Star Cutter Acquires Tru Tech Systems

Star Cutter Company has acquired Tru Tech CNC grinding systems from Resonetics (Nashua, N.H.), assuming all design and manufacturing of the Tru Tech high precision CNC grinding machines currently performed at the Michigan facilities in Mt. Clemens and Lewiston. Additionally, Star Cutter secures the service, training, and spare parts support for Tru Techs’ vast installation base across North America and Europe.

“Tru Tech is a strategic purchase that perfectly complements our existing business,” said Brad Lawton, Star Cutter Company chairman and CEO. “It expands our technology offering to address earlier operations in the tool grinding process. New capability in blank preparation and cylindrical grinding, as well as Tru Tech’s large install base, will create synergies with Star Cutter Company’s existing business units. This is a true win-win that benefits both our company and, most importantly, our customers.”

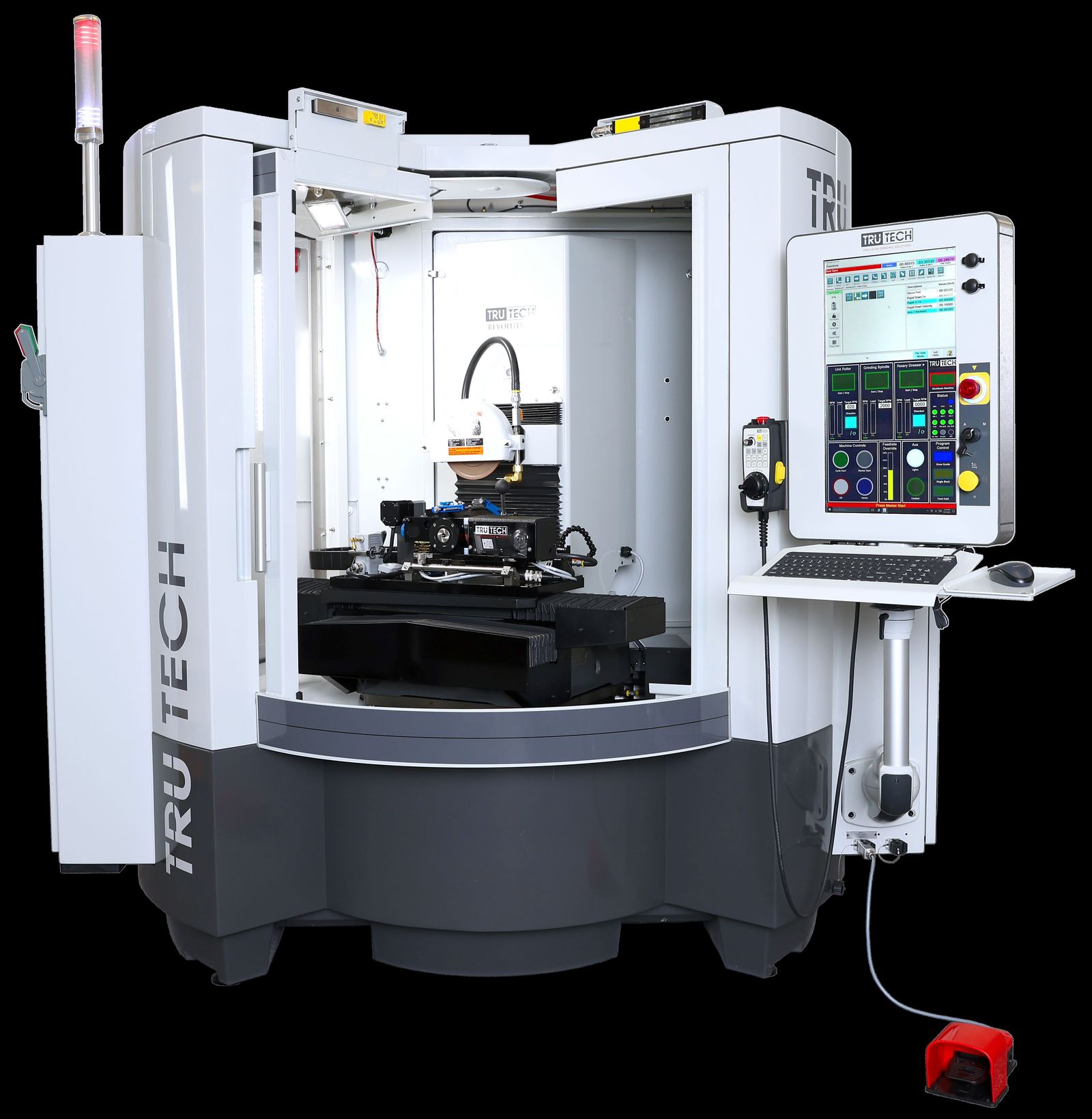

A key differentiator of the Tru Tech systems is their ease of use and ultrafast set-up while delivering great accuracy and repetitive results. Tru Tech’s Perimetric™ grinding technology and CNC Pick-N-Place™ software enable these machines to achieve extremely high accuracy suited for high precision and micro components in the medical, aerospace, electronics, and other industries. These systems are also capable of handling diverse needs from one-piece, small lot runs through lights-out production.

Star Cutter’s experience in carbide pre-forms, high-end custom tool production, tool grinding, reconditioning services and customer services, backed by a global 700-employee deep and financially strong global organization, ensures continued investment in Tru Tech’s people, machine platforms and service capabilities. For the near future, all Tru Tech employees will continue to function as they have at the Mt. Clemens and Lewiston operations with the Tru Tech machines and offerings ultimately becoming part of Star Cutter’s Machine Tool business unit.