Training: Invest in Your Most Valuable Asset

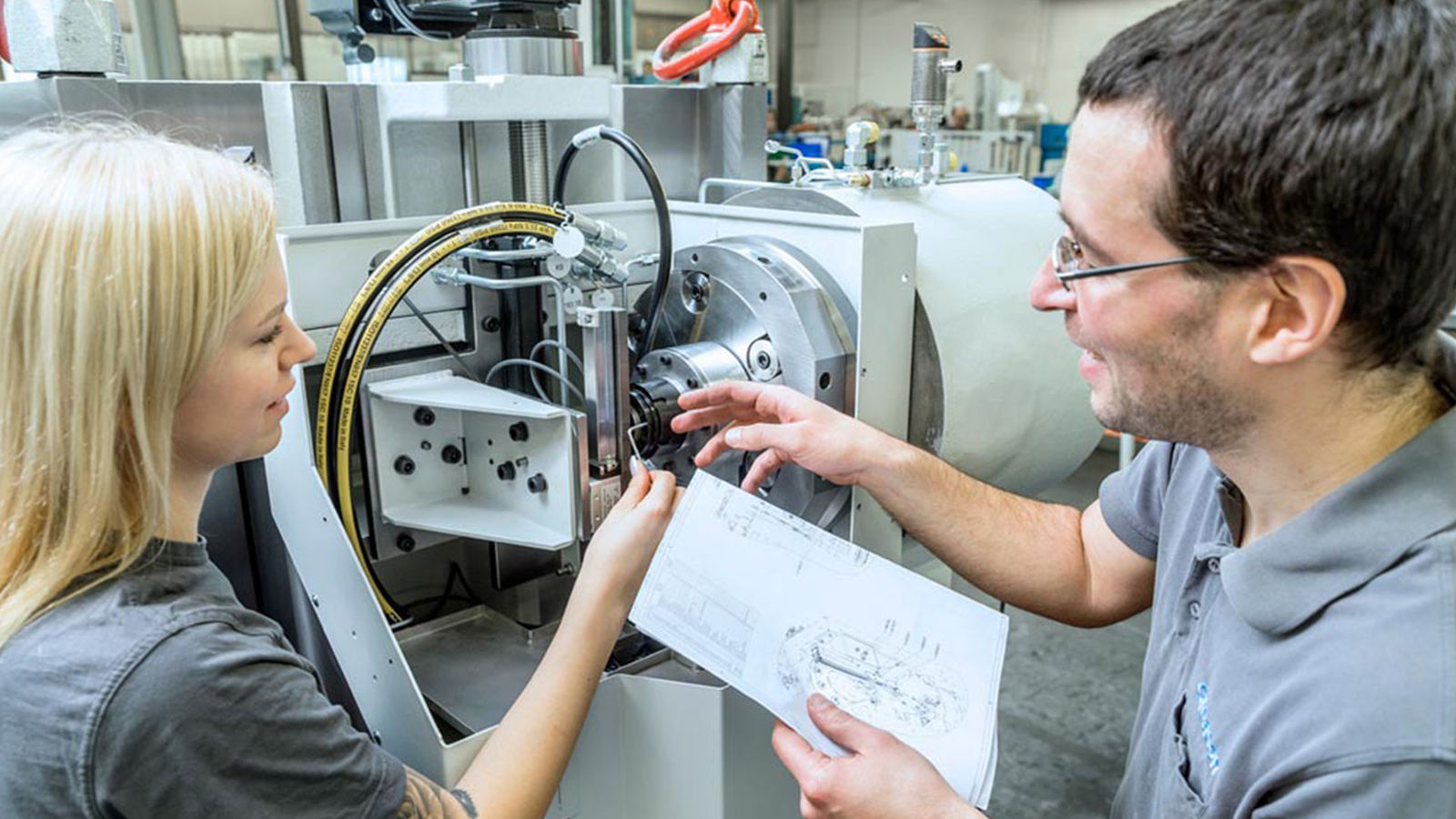

New training programs and digital training technologies are closing the gap between shortages in skilled workers and an increasingly complex manufacturing environment. People are your most valuable asset, and investments in training pay enormous dividends downstream.

In addition to scheduling training events on important topics throughout the year, Gleason also offers individualized Training Courses, constructed to meet specific participant requirements.

By 2030, it’s estimated that over 2 million manufacturing jobs in the US will be unfilled because of a lack of qualified talent. The CEOs of most manufacturers will tell you that their biggest challenge isn’t machines or materials—it’s manpower, and a global shortage of skilled workers. The gap between skilled technical positions and people with the training to fill them is perhaps at its widest since the dawn of the Industrial Revolution. Manufacturing technology, whether EV or AI, robots or cobots, is racing ahead at breakneck speed, and leaving older workers, and fewer, younger, and less skilled replacements behind.

Yet, for those manufacturers with the corporate cultures, work environments, and foresight to fully embrace training, there’s never been a better time, or more tools, to take learning to the next level. These companies view training as an investment in their most important asset, skilled workers—and the benefits are significant:

- More productivity: Today’s gear (and non-gear) production and inspection machines are designed to deliver exceptional productivity while relying less on the skills of the operator. Yet, the average machine operator or maintenance technician is today stretched thinner than ever. They must be more versatile than their predecessors, and able to manage a complex array of new technologies. With the right training, operators of these new technologies can help companies meet their ambitious production and quality objectives.

- Improved quality: Collaboration, and innovation, are byproducts of a strong learning environment. These workers are taught to strive for excellence and relish the challenges, and rewards, that come from high-quality efforts and outcomes.

- Greater safety: Today’s manufacturing environments are highly complex. Operating both efficiently and safely in these demanding workplaces requires that everyone from machine operators to maintenance technicians understands what’s at stake. Safety protocols, standards, and best practices can be deeply engrained in the workforce through training, thus helping avoid the cataclysmic costs of a safety-related accident.

- Exceptional employees: A company that nurtures learning as part of its culture has a decided advantage when hiring, training, and retaining skilled, highly motivated workers. These workers gain valuable skills faster and participate in a work environment that fosters greater satisfaction and a sense of accomplishment.

Train to Win

Traditionally, workers gained many of their technical skills over the years, whether in a technical trade school or apprenticeship and then on the job in close cooperation with older, more experienced tradesmen and technicians. This tried-and-true formula worked well when skilled labor was abundant, and a seemingly endless pipeline filled with eager applicants. Today, the Factories of the Future are, by design, much leaner, and the learning curve from novice to expert is considerably shorter. Nor are there nearly so many technical schools or skilled tradesmen to rely so heavily on.

As a result, training has quickly evolved in recognition of the new realities of the factory floor. The training tool kit has never been more diverse or effective. Training regimens today, at the best companies, are analogous to those of the most successful professional sports or Olympic teams. Instead of weight room, nutrition, and practice, workers use digital webinars, simulations, and classrooms. If modern training tools and techniques result in faster, higher, and stronger on the athletic field, they also produce faster, smarter, and better for companies seeking a competitive edge in the marketplace.

Knowledge Is Power

For Gleason, coupling training with technology, and sharing its deep know-how with all, has been a way of life almost since its inception in 1865. Who among the major automakers and their gear suppliers, for example, hasn’t sent a gear design engineer to the Gleason Gear School over the years? Today, Gleason now offers what is considered the industry standard for the training of engineering, production, purchasing, and administration personnel at those companies that produce and consume gears. These training programs are flexible, digital, comprehensive, global, and, perhaps most importantly, affordable (even, in many cases, free of charge). Consider all that’s now available to you: