Haas grinding centers can be found in state-of-the-art manufacturing facilities worldwide. Industries include medical engineering, precision tool manufacturing, gear manufacturing, the aerospace industry, the energy industry, and more.

multigrind.com

Allways Precision, LLC

Booth #236723

Allways Precision specializes in remanufactured Cincinnati Centerless Grinders. Allways Precision has a large inventory of machines and original Cincinnati components in stock. Complete turnkey packages and full CNC upgrades are available. Plus, a complete line of automation for any part-handling solution.

centerless.com

Basaran Grinder Corporation

Booth #236817

American-based and family-owned manufacturer of high-precision CNC internal radius grinders, external cylindrical grinders, creepfeed grinders, and vertical radial grinders for aerospace, automotive, and job shops.

basarangrinder.com

Broach Masters / Universal Gear

Booth #237275

Broach Masters and Universal Gear are a complete source for all your tooling and production needs. We will supply you with the highest quality products and services that you and your customers expect.

broachmasters.com

Achieving Digitalization through Data DiversityScott Lowen, Software Product Manager at Zeiss Industrial Quality Solutions In modern manufacturing, digitalization is key to overcoming many challenges and achieving continuous process improvement. Implementing a successful digitalization strategy involves using the right metrology technology to accurately digitize, analyze, and connect parts as they move across the product lifecycle. With different stages of the product lifecycle requiring different metrology solutions, understanding the specific advantages of each technology for specific applications helps to understand which to use to achieve digitalization efficiently and sustainably. This session will focus on helping the IMTS audience understand how to achieve digitalization for continuous process improvement across the product lifecycle by applying a connected and efficient approach to data acquisition and analysis. IMTS audience members will also understand how to strategically select the optimal metrology technology to collect accurate data to feed into digital twin and digital transformation initiatives efficiently. IMTS audience members will benefit from learning how to tap advantages driven by digital twin methodology. For example, they will learn to reduce costs and save time with digital assembly analysis powered by accurate 3D measurement data.

Thursday, September 12; 3:15 PM–4:10 PM LOCATION: W193-A |

Cincinnati Gearing Systems

Booth #236776

Cincinnati Gearing Systems (CGS) specializes in precision component gear manufacturing and design engineering. CGS has over 115 years of experience producing high-quality, reliable, and cost-effective component gearing and gear units for a wide range of power transmission applications.

cincinnatigearingsystems.com

Darmann Abrasive Products, Inc.

Booth #237218

Darmann Abrasive Products, Inc. designs, manufactures, and markets fine-grit, bonded abrasive products for superfinishing and precision grinding applications.

darmann.com

Dontyne Gears, Ltd.

Booth #237227

Dontyne Gears provides gear design and analysis services with prototyping and testing options.

dontynegears.com

DTR Corporation

Booth #237017

DTR is a global gear-cutting tool brand. As a total solution company, as well as manufacturing and sales of gear-cutting tools, DTR supplies production facilities, tool management services, coating services, and environmentally friendly machining technologies.

dtrtool.com

DVS Technology Group

Booth #236920

The DVS Technology Group brings together some of the most experienced and innovative mechanical engineering companies in Germany for high-precision gearing and ultra-fine surface machining, focusing on turning, grinding, skiving, gear cutting, and gear honing technologies. As a unit, DVS is a leading system provider in the global marketplace.

dvs-technology.com

EMAG L.L.C.

Booth #237047

If your company machines metal components, manufactures gears, and uses laser welding or electro-chemical machining, EMAG can provide automated machinery, from standalone pick-up turning machines to complete machining lines capable of manufacturing entire workpiece families.

emag.com

EST Tools America (Ever Sharp Tools)

Booth #237120

Custom gear cutting tools, broaches (round, helical, flat), hobs, skives, milling cutters, spline gages (functional and variable—ISO 17025 certified), industrial machining tools, annular cutters, drilling and milling tools, CNC broach sharpening and repair.

est-us.com

Excellence Gear Co., Ltd.

Booth #236060

Excellence Gear Company provides high-precision spiral bevel gears to a wide range of industries.

exce-gear.com.tw

Gear Technology (AGMA Media)

Booth #237314

Gear Technology, published by the American Gear Manufacturers Association, is the journal of record for the gear industry and includes technical articles and in-depth features about trends and technologies in gear design, manufacturing, inspection, heat treating, and much more. Power Transmission Engineering, the magazine of mechanical components, provides the latest product and technology news about gears, bearings, motors, and gear drives.

agma.org

geartechnology.com

powertransmission.com

General Broach Company

Booth #237229

Over 80 years in business as a designer and manufacturer of linear broaching tools, machines, and turnkey applications for the gear, turbine, hand tool, off-road, and firearm industries.

generalbroach.com

German Machine Tools of America

Booth #237126

Sales and service organization and distributor for various German machine tool companies. Specialized in turnkey solutions and over 25 years in business supplying the automotive industry with sales and service locations in the USA and Mexico.

gmtamerica.com

Gleason Corporation

Booth #236909

Gleason is a global leader in gear technology ranging from gear and transmission design software to the development and production of gear manufacturing machines and related accessories, gear metrology equipment, and automation systems. Gleason products are used by customers in the automotive, commercial vehicle, aerospace, agricultural, mining, energy, construction, power tool, marine, and many other industrial equipment markets. Gleason has manufacturing facilities in the U.S., Brazil, Germany, Switzerland, India, China, and Japan, and operates sales and service offices in North and South America, Europe, and Asia Pacific.

gleason.com

Haller Intelligent Equipment Co.,Ltd.

Booth #237072

Haller Intelligent is a manufacturer of high-precision CNC machines, providing solutions for tool and parts processing. They have different series of CNC machines, such as tool grinding machines, cam grinding machines, and gear chamfering machines. Widely used in automobile, aviation, electronic, medical, etc. fields.

szhaller.com

Hammond Roto-Finish Co.

Booth #237020

Hammond Roto-Finish has adapted to new developments in manufacturing as well as pioneered many innovations in the polish-and-buff and mass-finishing sectors of manufacturing. Today, Hammond serves multiple industries with a wide range of capabilities for both robotic deburring and finishing (including painting) and offers new applications in mass finishing for vibratory finishing, centrifugal energy, and the development of finishing processes.

hammondroto.com

Heinz Berger Maschinenfabrik GmbH & Co. KG

Booth #237117

The Berger Gruppe produces machines and robotic cells for grinding, polishing, edging and profile-generating workpieces, and steel strips. The product range consists mainly of approximately 250 mostly CNC-controlled machine types as well as more than 950 robot integrations.

bergergruppe.de

Helios Gear Products, LLC

Booth #236906

Helios Gear Products crafts personalized machine, cutting tool, and abrasive tool solutions to equip gear manufacturers for profitable production.

heliosgearproducts.com

Inductoheat

Booth #237030

Inductoheat brand induction heat treating equipment utilizes patented technology for today’s automotive, aerospace, agriculture, off-highway, railroad, and renewable energy industries. From high-speed copper tube annealing to stationary camshaft heat treating, Inductoheat induction heat treating equipment offers a solution.

inductothermgroup.com

KADIA Inc.

Booth #237118

Kadia specializes in high-precision bores and burr-free workpiece surfaces. Kadia develops high-end honing technology for small to medium-sized bore diameters and mechanical deburring and finishing of surfaces. Kadia offers turnkey systems for the processing of complex workpiece contours.

kadia.com

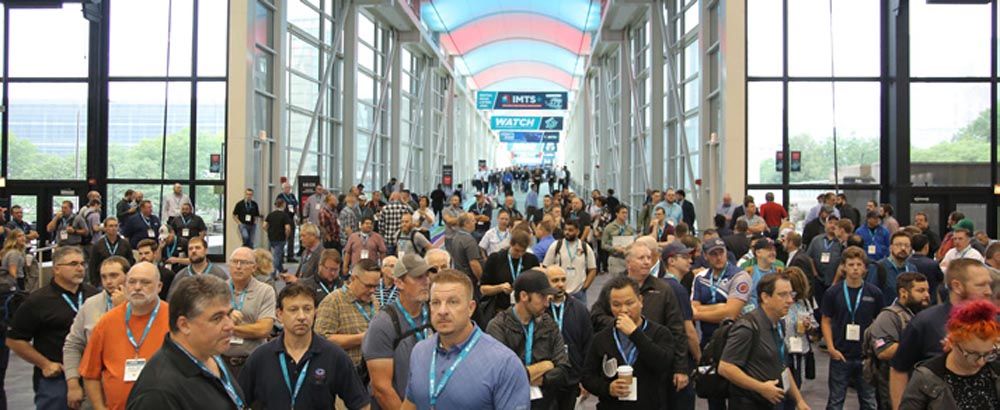

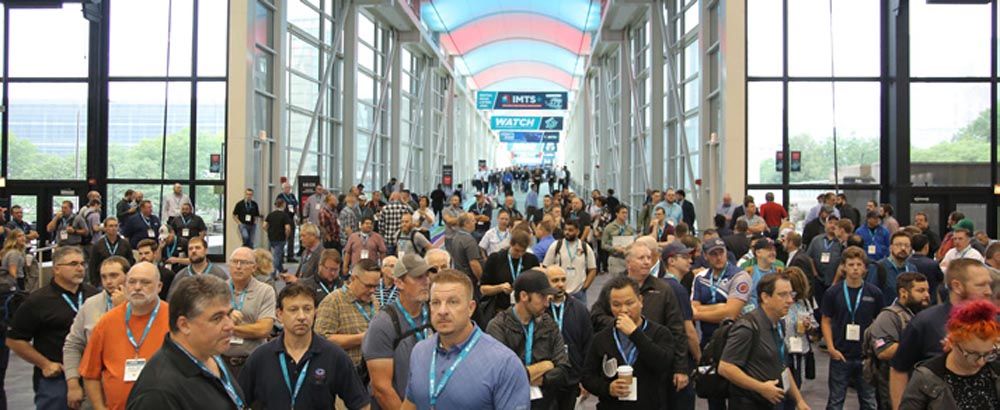

Chicago will be the epicenter of the manufacturing world as an estimated 100,000 people will attend IMTS which runs from Sept. 9–14 at Chicago’s McCormick Place with more than 1.21 million sq. ft. of exhibit space hosting over 1,800 exhibitors.

Kapp Technologies, LP

Booth #237024

Kapp Niles is a global market leader guaranteeing precise and cost-effective technology for grinding and inspecting parallel axis involute gears and other sophisticated components. With our purpose-built machine series, we meet the needs of every gear application and noninvolute precision profile.

kapp-niles.com

Liebherr Gear and Automation Technologies, Inc.

Booth #236914

Liebherr Gear and Automation Technologies, Inc. offers a complete program of gear technology and automation solutions. Liebherr manufacturing machines include gear hobbing, shaping, skiving, chamfering, gear grinding machines, and gear metrology solutions. Liebherr automation systems range of solutions are cost-effective, user-friendly, high-quality, and offer the flexibility to expand retrospectively.

liebherr-us.com

Matrix Machine Tool (Coventry) Ltd.

Booth #236744

Worm thread grinding machine, hob sharpening machine, gear grinding machine, external/internal thread grinding machine, and gear tools.

matrix-machine.com

Nidec Machine Tool America

Booth #237238

Nidec Machine Tool America manufactures gear-cutting and finishing machinery, broaching machinery, gantry and boring mills, OD grinders, 5-axis machining centers, 3D printing machinery, wafer bonding technology, gear-cutting tools, and broach tools and tooling. Featuring in-house sales, service, and parts support.

nidec-machinetoolamerica.com

NUM Corporation

Booth #236609

Manufacturer of CNC automation solutions. Products include servomotors, servo drives, switching cabinets, drives, and CNC controls. Services are also provided for retrofitting, design, and training. Headquartered in Switzerland, NUM currently has more than 35 global sales and service locations.

num.com

René Gerber AG

Booth #236918

René Gerber AG is a Swiss precision technology company in brush deburring, edge honing, and polishing solutions. They offer 65 years of experience in the process development and construction of brush deburring machines, edge-honing machines, and polishing equipment.

gerber-maschinen.ch

Rotec Tools Ltd.

Booth #237223

Representing: Affolter—Gear Hobbing Machines; pL Lehmann—Rotary Tables; Greber—High Precision Centers; Fisso—Articulated Arms; and FN Niederhauser—Precision Chucks.

rotectools.com

S.L. Munson & Company

Booth #237240

S.L. Munson & Company is a distributor of precision diamond dressing products and conventional and super-abrasive grinding wheels. They are also a manufacturer of conventional internal grinding wheels and a producer of vacuum-brazed abrasive products for a wide range of applications.

slmunson.com

Star Cutter Company

Booth #237013

Headquartered in Farmington Hills, MI, and originally founded in 1927, the Star Cutter Company is a global leader in the cutting tool industry with over 700 employees working in 15 manufacturing facilities. Each facility specializes in producing a specific type of product or service: carbide blanks and preforms, solid carbide cutting tools, gundrills, PCD tooling, gear cutting tools, and 5-axis CNC tools and cutter grinding machines. Star SU LLC is the marketing, sales, and service partner in North America, South America, Europe, and the Far East.

starcutter.com

Ty-Miles, Inc.

Booth #237106

In 1958, Ty Miles Inc. started manufacturing a complete line of broaching systems. Today, the range runs from 2–50 ton and 12–90 in. stroke (vertical, horizontal, and table-up) machines. They build special machines that can include broaching with other secondary operations. They provide broach tooling, reconditioning, and production broaching services in-house.

tymiles.com

United Grinding North America, Inc.

Booth #236802

United Grinding North America, Inc., a subsidiary of the United Grinding Group, represents a union of leading companies in grinding and ultra-precise finishing solutions for the manufacturing industry. Through its surface and profile grinding, cylindrical grinding, and tool grinding technology groups, the company sells and supports precision machines for grinding, eroding, laser ablation, combination machining, and measuring under the Mägerle, Blohm, Jung, Studer, Schaudt, Mikrosa, Walter, and Ewag brands. Headquartered in Miamisburg, Ohio, United Grinding North America is ISO 9001 certified to ensure quality in product development, production, shipping, and support operations.

grinding.com