WAFIOS and Gehring Offer e-Mobility Innovations for High Performance Production

The medium-sized mechanical engineering companies Gehring, NAGEL and WAFIOS as well as Lambda Resins GmbH will be presenting their latest developments in the field of e-mobility at the Reutlingen E-Mobility Days 2024 (RED). The renowned specialist forum, initiated by WAFIOS and held this year for the first time on the new e-mobility campus, will take place from October 15–17, 2024 and is regarded as the central platform for innovations in e-mobility.

Around 12 co-exhibitors will also be on site to present a wide range of e-mobility solutions. Top-class presentations by experts on the latest trends and developments in electromobility will round off the program.

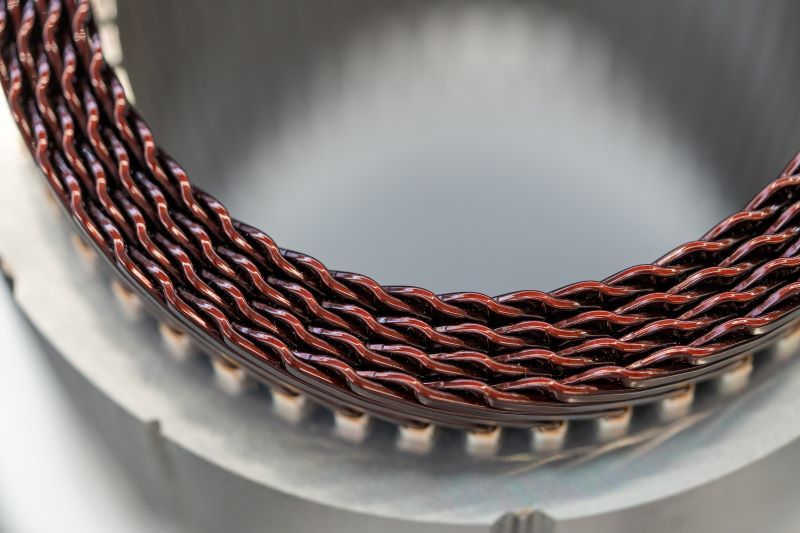

Gehring and WAFIOS will be presenting comprehensive turn-key production lines and individual exhibits for the manufacture of electric motors at the REDs. These include high-precision stators and bent pins produced on the latest CNC bending machines.

Dr. Uwe-Peter Weigmann, CEO of WAFIOS, explains: "With its hairpin bending technology, which is fully controlled via CNC axes, WAFIOS combines maximum flexibility with high production output for the first time. This makes it possible to produce hairpins with different geometries and wire dimensions using one production system in automatic mixed operation."

Since April 2021, Gehring and WAFIOS have been combining their expertise to offer the automotive industry turnkey production lines for the manufacture of electric motors worldwide. The two companies rely on innovative technologies and their many years of experience in automotive manufacturing.

A special highlight at the trade fair will be the presentation of two FMU E 40 machines from WAFIOS and a SpeedFormer. One of the FMU E 40 machines will be used to demonstrate the development of hairpins in a continuous hairpin, while the other machine will showcase a new slide feed and HQ bending, a new bending technology. To produce the shaft winding, WAFIOS is drawing on its well-known expertise in meander production in the tube sector and developing it further based on the latest hairpin bending technology. SpeedFormer demonstrates the latest advances in bending technology, such as the production of different geometries without changing tools. In addition to the broad portfolio for hairpins, the BMF 60 busbar machine will also be on show. It presents mechanical stripping and can be integrated into automated systems.