The Next Chapter in Heat Treatment

Low Pressure Carburizing Benefits EV Market, In-House Heat Treating, Energy Initiatives and Automation

The challenges discussed in our recent “State of the Gear Industry Survey” follow a similar pattern across the entire manufacturing sector. Skilled labor issues, stricter energy regulations, and a desire to upgrade equipment are just as relevant in heat treating.

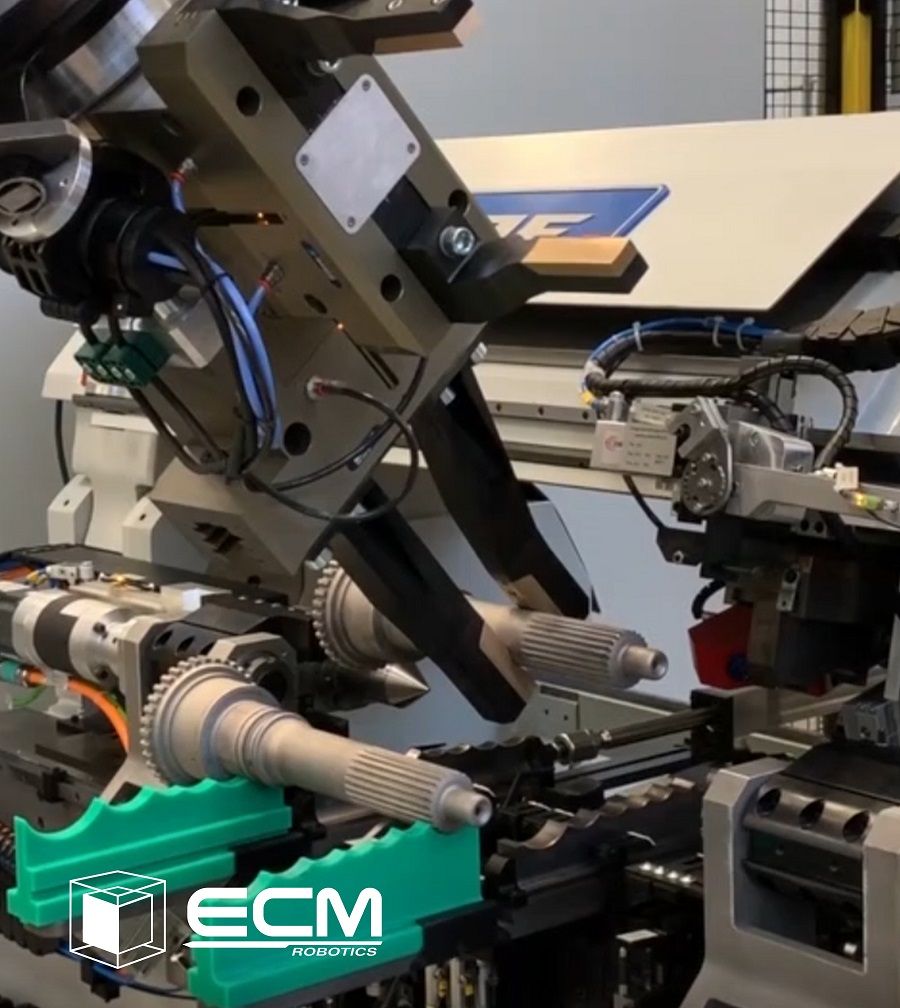

Today, gear manufacturers would like to replace costly subcontract work for in-house capabilities, and provide additional robotic, automation and green energy benefits to their customers. Low pressure carburizing (LPC) provides a path to these technologies.

“Because low pressure carburizing (LPC) is highly repeatable and the recipes just run and run with very little adjustments or tuning, we’re seeing a lot of this technology going in-house at GM, Ford and Stellantis,” said Bill Gornicki, director of sales at ECM USA, Inc.

“In addition, thanks to all the new players in the global electric vehicle (EV) market, we’re seeing new production in China, Europe and India all going to LPC as well,” said Dennis Beauchesne, general manager at ECM USA, Inc. “LPC technology provides a better environment to operate in. It’s more like a machine tool with processing that provides precise and repeatable results, capabilities everyone is looking for in the EV sector.”

Clean and Green

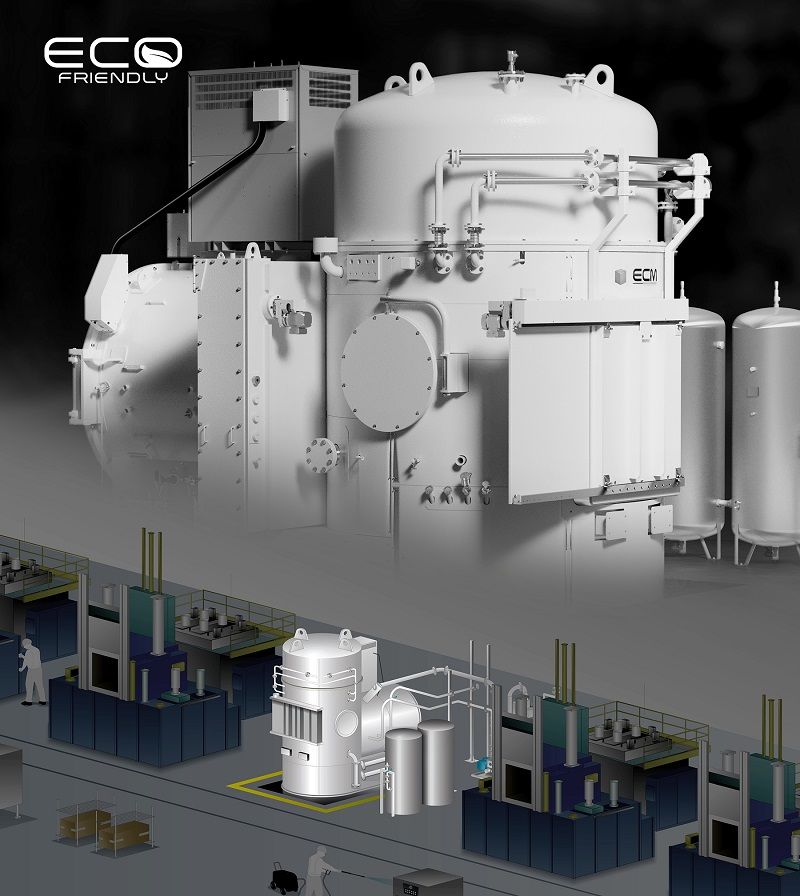

ECM Technologies developed Infracarb in the 1980s. The Infracarb process is fulfilled under low pressure. The carbon donator gas is Acetylene C2H2 – used during the enrichment phases, and nitrogen N2 is used during the diffusion phases. The process temperature is generally higher than traditional carburizing, between 880 and 1,050°C thanks to the vacuum technology. The high temperature processes help reduce carburizing cycle time in comparison to traditional atmosphere carburizing.

Gornicki said the technology opposes everything most people think about when they consider the history of heat treatment.