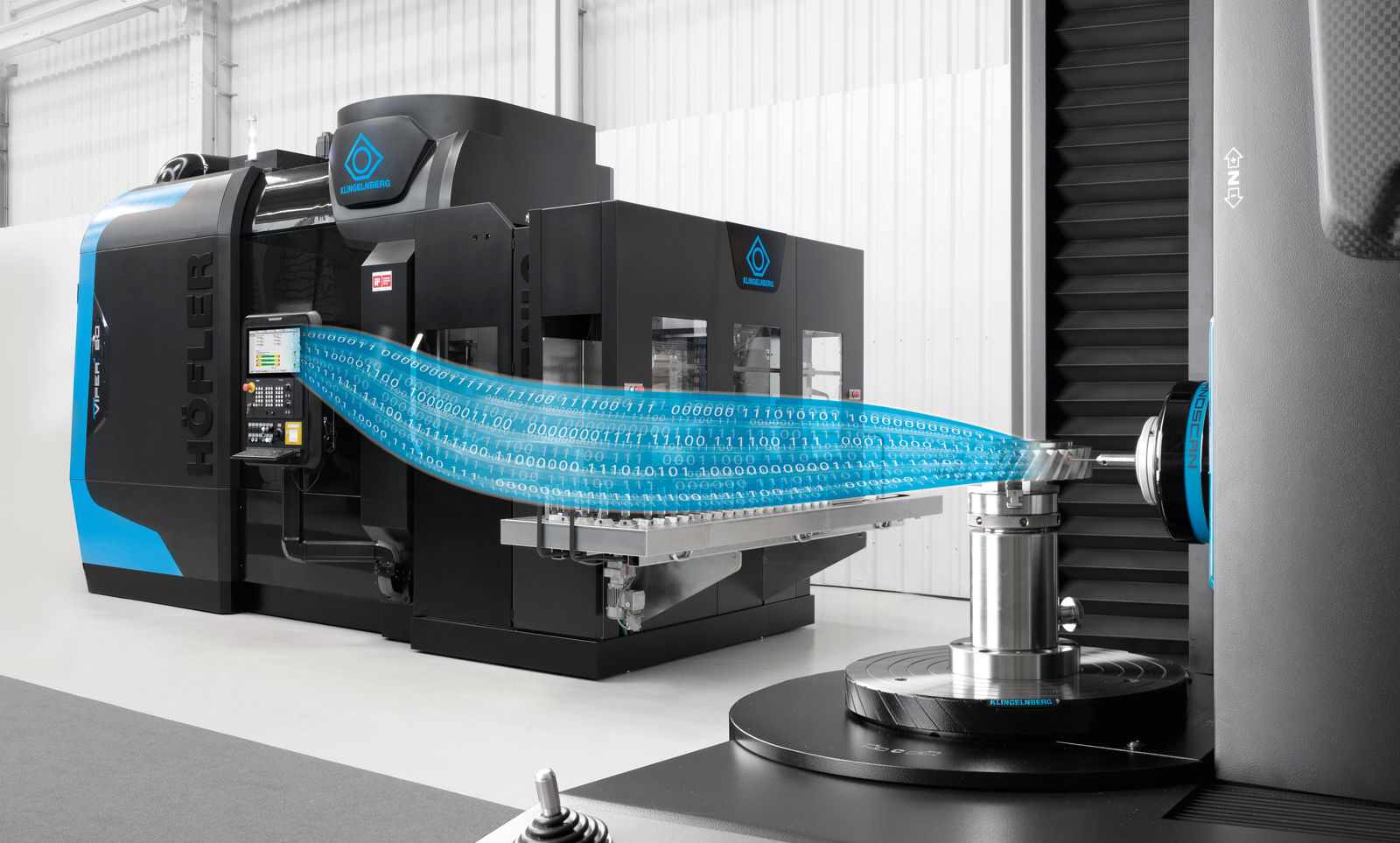

“As a result, we know what best available technology can guarantee the results we expect. When our DCT project required the purchase of a gear grinding machine, we looked for options that met our requirements,” Simental said. “Klingelnberg introduced us to the Höfler generating gear grinding machine, Speed Viper. Speed Viper is capable of maintaining quality standards in high-volume gear production. It guarantees the microgeometry that our gears need in order to meet the design requirements.”

With the closed loop technology that connects Tremec’s measuring machines to the Speed Viper, the system calculates and analyzes the results automatically and suggests the required corrections where necessary in order to keep the process within the previously defined parameters. And the operator always has the freedom to accept the suggestions made by the system, or not.

“The Speed Viper also has one of the most user-friendly graphical user interfaces that we have available. On the touchscreen display, it is extremely easy to switch between applications during the settings. And during the setup process, the software guides the operator step-by-step through the application. With the Speed Viper, we are able to avoid quality problems associated with over-adjusting the process,” Simental added.

From left to right: Adrián Hernandez, managing director, Klingelnberg México S.A. de C.V., Javier Rivera, DTC gear production manager at Tremec, Hector Simental, operations manager at Tremec.

From left to right: Adrián Hernandez, managing director, Klingelnberg México S.A. de C.V., Javier Rivera, DTC gear production manager at Tremec, Hector Simental, operations manager at Tremec. Simental mentioned four factors that illustrate why the Speed Viper works so well in this production environment.

“First, the

Gear Designer software that we use to create programs and simulations to optimize the results of the microgeometry, cycle times, tool life, etc. Second, the closed loop system to keep the process under control. Third, an orderly sequence of steps when setting up the machine helps avoid human error – and trains the operators at the same time. Fourth, the machine’s rugged design is a key advantage,” Simental said.

The closed loop system, in fact, has exceeded expectations in terms of process control. The Speed Viper integrated seamlessly, so to speak, into the process landscape with flat hierarchies and a continuous material flow. As a result, Tremec was able to meet customers’ requirements for quality and delivery times.

The biggest project challenge was the extremely brief period of time they had available to develop the process and start production.

“Klingelnberg was at our side throughout the entire development phase up to start of production, which we achieved in record time. Technical support was always available whenever we needed it, both remotely and on-site. This was true for both the machine and the tools. For us, it’s not just about buying machines. Instead, we aim to form technology-based alliances with our suppliers that will enable us to grow together,” Simental said.

Meeting Mass Production Demands

Adrián Hernandez, general manager of the Mexican subsidiary at Klingelnberg, discussed how the Speed Viper can evolve in the IIoT environment.

“We offer a future-oriented platform achieved through software solutions on the one hand, but also through clear user interfaces on the other. Our customers have different automation systems, and we must be able to integrate our machines into any automation solution,” Hernandez said. “That is why the Speed Viper features a universal interface and can be combined with any automation system. The Speed Viper is ideally suited to meet the demands of mass production and was developed primarily to achieve minimal cycle times, minimal tool costs and high energy efficiency.”

Closed Loop Data Flow for Cylindrical Gears

As a result of the development, data records are released for production and stored in a database. This data record contains a virtual twin of the cutting machine and the manufactured component, according to Hernandez.

“The operator uses the Gear Operator software on the Speed Viper to retrieve the data record for production. This is where the tool geometries and process kinematics are stored. It is also where process data, such as the cutting speed and the feed rate, are defined,” Hernandez said. “This ensures that a gearing will always be ground using the same parameters, regardless of which Speed Viper and which operator. When a gear is measured on a P-machine, this result is stored in a database. At the same time, the operator of the Speed Viper is notified that a new measuring result is available. A wizard helps the operator to correct the process.”

This results in a faster, more efficient production process that can be fine-tuned and upgraded in the future to meet the changing needs of the customer.

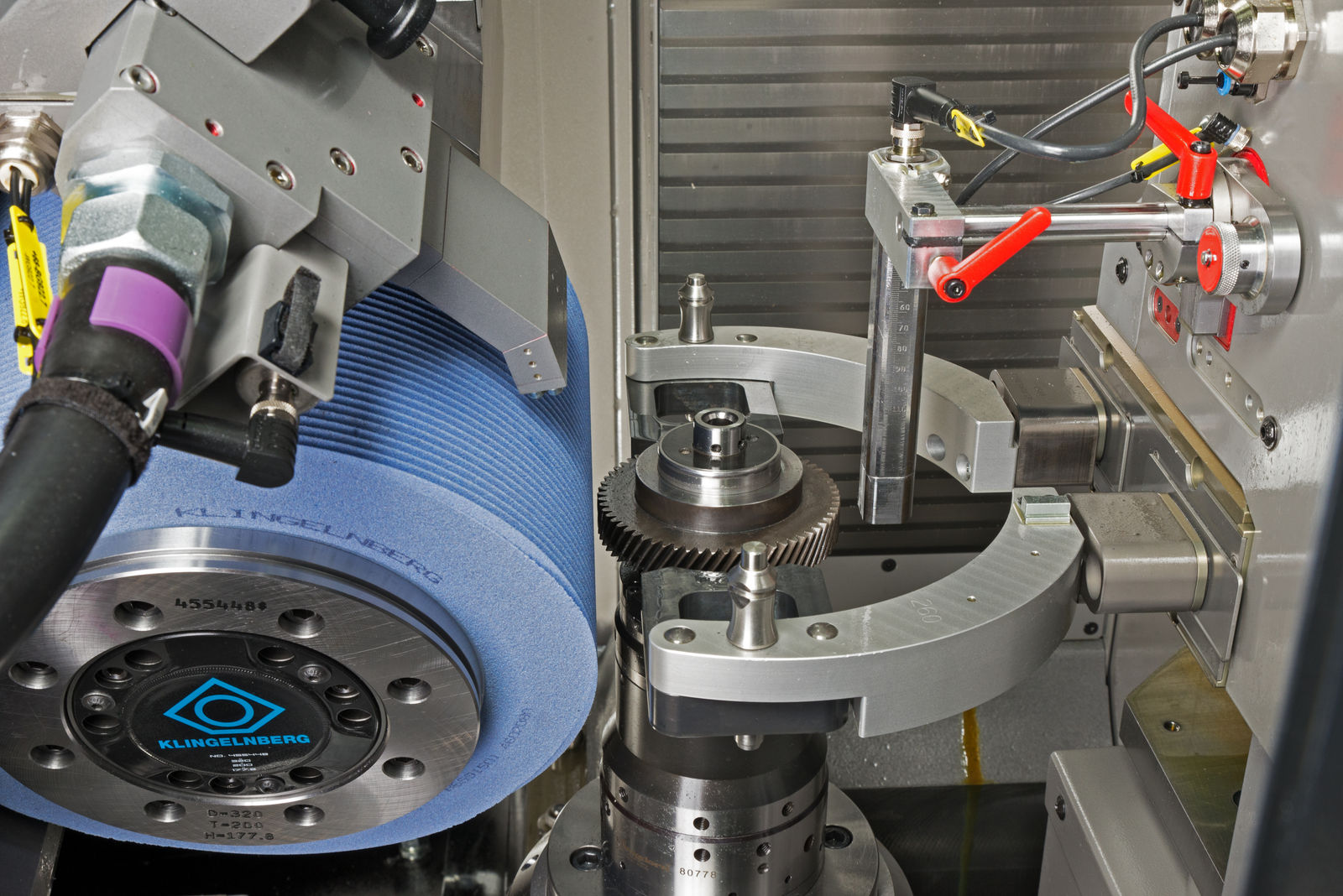

Closed loop technology on the Speed Viper.

Closed loop technology on the Speed Viper.