Corrected Lead Hobs

Understanding their use cases and machine settings

During our interactions with customers, we find the common challenge faced by customers about getting incorrect component parameters using corrected lead hobs.

To address the challenge, we will talk about what corrected lead hobs are, why it is necessary to design such hobs, and how to set up the hob on the machine depending upon the type of hobbing machine (manual, semiautomatic CNC, or CNC).

What Is a Corrected Lead Hob

The module and pressure angle of corrected lead hobs are different from the module and pressure angle of the component. If the pressure angle of a hob is less than that of the component, then it is a short lead hob and if the pressure angle is greater, then it is a long lead hob.

Why It Is Necessary to Design Corrected Lead Hobs

When the true involute form (TIF) diameter and fillet radius of a component is not achieved with a standard design, then the pressure angle of the hob is reduced or increased to obtain the correct TIF and fillet radius of the component. This can be explained with the below example.

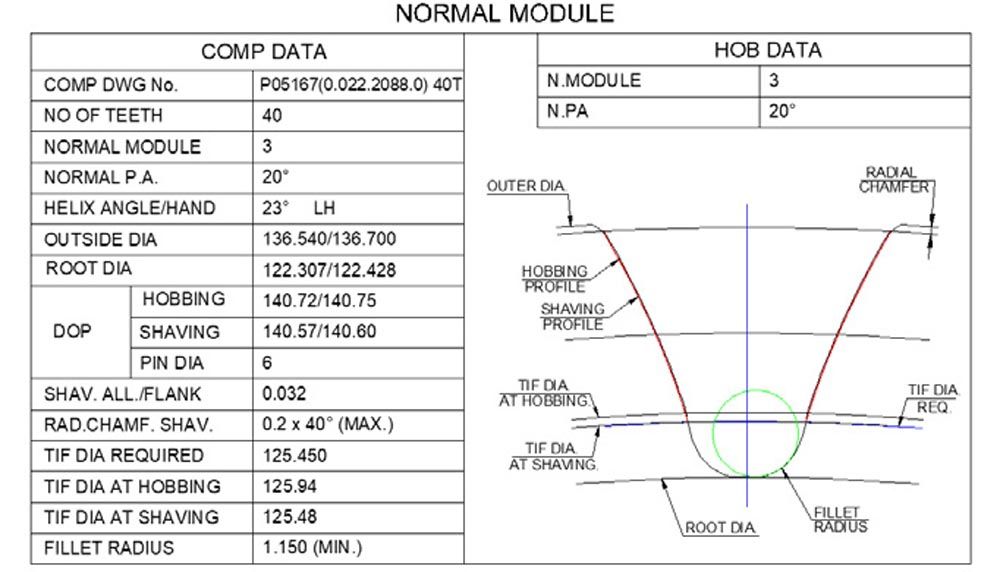

Figure 1—Component generated profile with standard design. Figure 1—Component generated profile with standard design. |

Standard Hob Design

Principally, TIF shaving should be below the required TIF diameter. However, when the hob is designed with the standard method, TIF required and TIF shaving are almost at the same values. Please refer to the component generated profile in Figure 1.

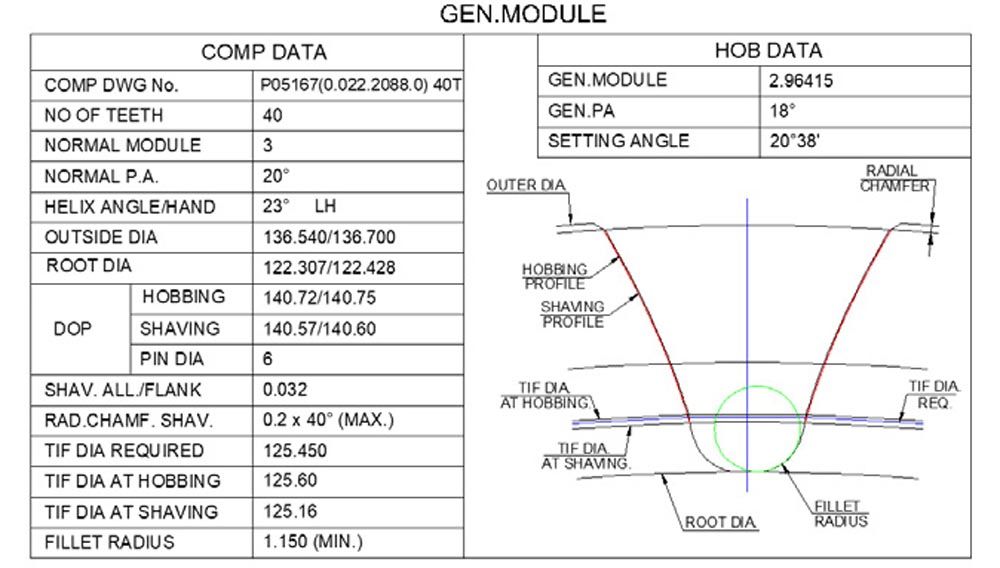

Figure 2—Component generated profile with corrected design. Figure 2—Component generated profile with corrected design.

|

Corrected Lead Hob Design

To achieve the principal requirement of getting TIF shaving below TIF required, the pressure angle of the hob is reduced from 20 degrees to 18 degrees. Please refer to the component generated profile in Figure 2.