Distortion Study and Results

Case hardening as a heat treating process was chosen for gears of a new generation of six-speed, automatic transmissions. In order to meet automotive’s high quality demands, vacuum carburizing and high-pressure gas quenching are used as heat treating technologies. Due to the geometry and manufacturing process, these parts are susceptible to distortion during heat treatment. Therefore, an intensive process optimization program has been started where transmission manufacturers and furnace suppliers work in cooperation. To optimize the heat treatment process, it is important to differentiate between the distortion created by heat treatment and distortion created by the release of internal stresses resulting from the steps preceding the final heat treatment process. While the former can be minimized by optimizing the heat treatment process parameters, the latter can only be influenced by changes in the pre-processing route after an intensive study of the entire manufacturing chain of the part.

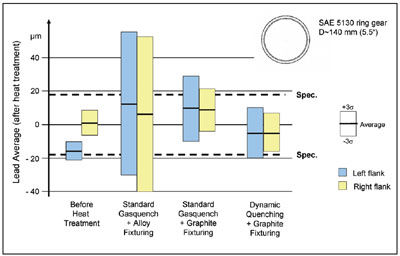

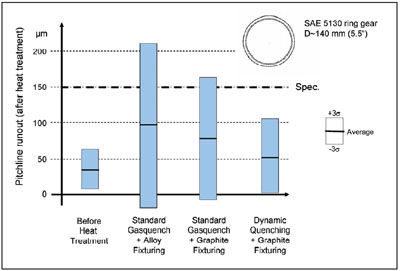

The results of the optimization of the heat treatment with particular focus on the gas quenching process are shown in Figures 4 and 5. Full loads with multiple layers of ring gears of SAE 5130 were heated in a ModulTherm system by using convection and vacuum heating. Convection heating was used to secure a fast but uniform heat-up of the parts and to keep heating-induced stresses to a minimum. After being properly heated, the parts were vacuum-carburized at 900°C to a case depth of 0.3 mm to 0.5 mm by using acetylene. After vacuum carburizing, the temperature was reduced to austenitizing temperature and the parts were then gas-quenched with helium by using different quenching procedures and fixtures. Although the ring gears have a small wall thickness and the base carbon is relatively high, it has been demonstrated in preceding comparison tests that distortion results were better for gas quenching with helium than with nitrogen. Dimensional studies were performed on 15 parts, which were located on different layers in the load. Lead and profile deformation and pitch line run-out were measured using a CNC gear checker.

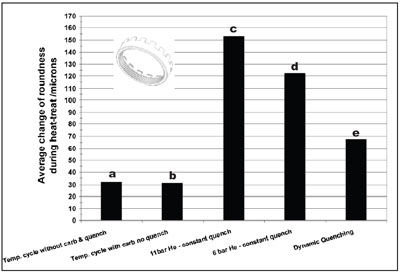

Figure 4 shows mean values and scatter of lead average after different heat treatments, compared with the green data. After heat treatment using standard gas quenching with constant gas pressure and velocity, the mean value of lead average increases moderately; but scatter increased significantly. By using the same quenching process—but changing from alloy to graphite fixturing—the scatter could be reduced by 50%. The best result was obtained by applying the dynamic quenching technique and by using graphite fixturing.

Figure 4—Lead average of ring gears before and after heat treatment.

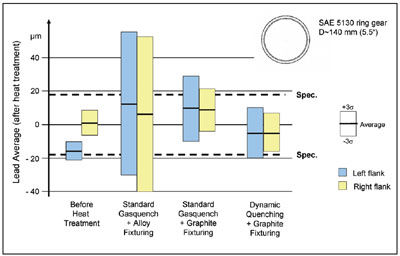

Figure 5 shows the results of the pitch line run-out after heat treatment. As with lead deformation, pitch line run-out could be significantly improved. The best result regarding mean value and scatter was again obtained by using dynamic quenching and graphite fixturing; with this technology, it is possible to reach the specified values. In all the performed tests, no influence regarding the position of the parts in different layers on the distortion behavior was observed.

Figure 5—Pitch line run-out of ring gears before and after heat treatment.

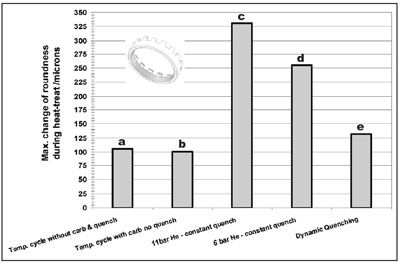

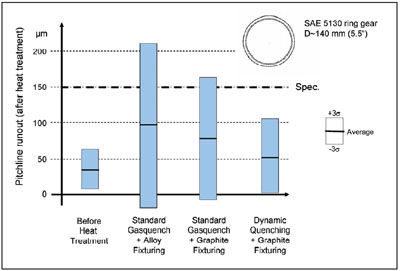

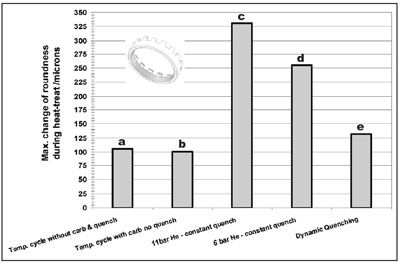

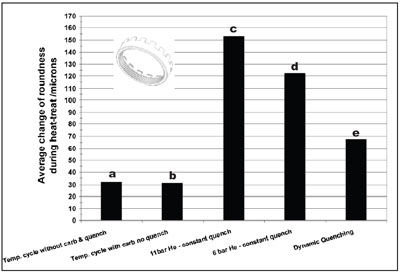

In a further test series, internal gears, also made of SAE 5030, were heat treated in a ModulTherm system by using different quenching process routes to investigate the distortion potential. The gears were convection-heated and vacuum-carburized with process parameters as described in the test series before. Graphite grids were used for fixturing in all tests. After the test, roundness measurements on 10 to 20 rings per load were performed using a DBB (distance between balls) machine. The resulting change of maximum and average roundness data before and after the test for the different heat treatment processes is given in Figures 6 and 7.

Figure 6—Maximum change of roundness (Dmax –Dmin) during heat treatment (Distance Between Balls [DBB] measurement).

Figure 7—Average change of roundness (Dmax –Dmin) during heat treatment (DBB– measurement).

The first set of parts had an original temperature cycle—but without carburizing. Afterwards, the parts were slow cooled in the furnace (a). This so-called “dead run” releases the internal stresses from the preceding manufacturing processes and forms a baseline for the effort of any quenching optimization for the subsequent heat treatment process. This test was repeated, but the parts were carburized (b); this had no influence on the result. For the next test, the parts were carburized and standard-gas-quenched by using 11 bar helium (c). This led to a significant increase in the maximum and average change of roundness after the heat treatment. Because core hardness after quenching of the parts was well within the specification, the quenching pressure was reduced to six bar in the next trial (d) to minimize distortion. The result was an improvement of the change-of-roundness data. In the last trial (e), the parts were carburized and quenched using the dynamic quenching technology, resulting in a further significant improvement of roundness data. Compared to the data of the dead run, maximum change of roundness is only increased by 25%. Compared to the data of the test using the standard gas quenching practice with constant parameters, distortion could be reduced by almost 60% with dynamic quenching technology. The results shown above are only a small portion of the complete optimization program performed together with the end-user in the automotive industry. However, they demonstrate the potential for distortion optimization using a proper quenching system and process technology, as well as fixturing. As a result, vacuum carburizing and gas quenching in this case were determined as the key technology for the heat treatment of a new generation of 6-speed, automatic transmissions worldwide.

Summary

The proper control of distortion after thermal treatment of powertrain components in the automotive industry is an important measure to ensure high part quality and to minimize subsequent hard-machining processes, thereby reducing the overall production costs. Vacuum carburizing (low-pressure carburizing) with subsequent high-pressure gas quenching represents an innovative heat treatment technology to reduce distortion in surface-hardening processes.

A series of heat treating tests, including distortion measurements on internal gears of a new 6-speed automatic transmission, were performed. It was demonstrated that by using innovative heat treating technologies—i.e., vacuum carburizing and high-pressure gas quenching, distortion of the gears can be effectively controlled. Optimum results were achieved by using proper furnace technology, graphite fixtures and application of dynamic quenching technology.

References

1. Gupta, C., G.Willet and A.Volkmann. “Flexible Vacuum Carburizing Systems.” Industrial Heating, September, 2003, pp. 87–90.

2. Hippenstiel, F., W. Bleck, B. Clausen, F. Hoffmann, R. Kohlmann and P. Pouteau. “Einsatzstähle als Mabgeschneiderte Werkstofflösung zur Hochtemperaturaufkohlung von Getriebekomponenten,” HTM Z. Werkst. Wärmebeh, Fertigung 57 (2002) 4, pp. 290–298.

3. Schmidt, G., E. Hägele, F. Preiber and P. Heilmann. “Getaktete Vakuum-Durchlauf-Wärmebehandlungsanlage- mit Hochdruck-Gasabschreckung.” Haerterei-Techn. Mitt. 54 (1999) S. 39-44.

4. Minarski, P., F. Preisser and R. Zenker. “Quenching Steel Parts in 20-Bar.” Advanced Materials & Processes, April, 2000, pp. 23–26.

5. Lübben, Th., H. Surm, F. Hoffmann and P. Mayr. “Mab-und Formänderungen beim Gasabschrecken.” HTM Z. Werkst. Wärmebeh, Fertigung 58 (2003) 2, pp. 51–60.

6. Löser, K. and V. Heuer. “Neue Entwicklungen auf dem Gebiet der Hochdruck-Gasabschreckung.” HTM Z. Werkst. Wärmebeh, Fertigung 58 (2003) 2, pp. 74–82.

7. Heuer, V. and K. Löser. “Entwicklung des dynamischen Abschreckens in Hochdruck-Gasabschreckanlagen.” Mat–Wiss. U., Werkstofftech, 34 (2003) pp. 56–63.

Dr.-Ing. Klaus Loeser studied mechanical engineering and received a Ph.D. as scientific assistant at the Institut of Materials Science of the Technical University in Darmstadt. He is director of the R&D department of ALD Vacuum Technologies GmbH, Hanau.

Dr.-Ing. Volker Heuer studied metallurgy and materials technology at the RWTH Aachen. He received his Ph.D. as a scientific assistant at the TU Bergakademie Freiberg. He is development engineer in the R&D department of ALD Vacuum Technologies GmbH, Hanau.

Donald R. Faron studied metallurgy and materials engineering at the New Mexico Institute of Technology (BS) and Northwestern University (MS). He is lead materials engineer of the central manufacturing department at General Motors Powertrain (automatic transmissions).