DVS Group Member Praewema Antriebstechnik Develops Precise Machining Solutions for Planetary Gearing

The DVS gearing specialist Praewema Antriebstechnik continues to expand its technological expertise in order to keep pace with the growing significance of planetary gear trains for automatic and particularly electric vehicles, with the associated need for even higher-precision production of toothed gear components. The company now offers holistic machining solutions for µm-precise production and optimization of both external and internal gearings. Here is a detailed look at the market and technology leader's extensive expertise when it comes to the complex production of inner-toothed ring gears for planetary gear trains.

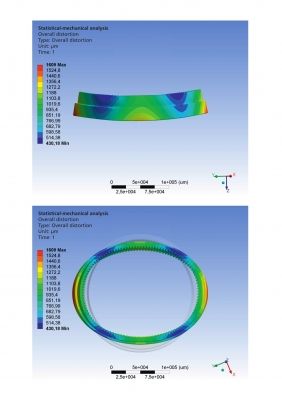

Planetary gear trains are predestined for installation in the powertrains of automatic and particularly electric vehicles. Compared to conventional spur gear stages, the planetary gear train makes it possible to divide the power flow into three or more strands. This permits higher transmission and reduction ratios to achieve greater performance density, while reducing weight and package aspects and improving running smoothness. As a result, they fulfill the existing need for higher torques with reduced package and weight for electric drives that stand out with higher motor speeds of up to 17,000 rpm.

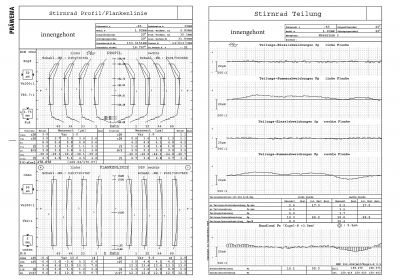

In terms of production, these factors lead to narrower geometrical tolerances and thus the complex demand for even higher precision NVH-optimized machining of corresponding planetary gear train parts, referring particularly to the quality of necessary gearings. Praewema Antriebstechnik fulfills these requirements with tailor-made technology, machinery and tool solutions for high-precision gear manufacturing and optimization.

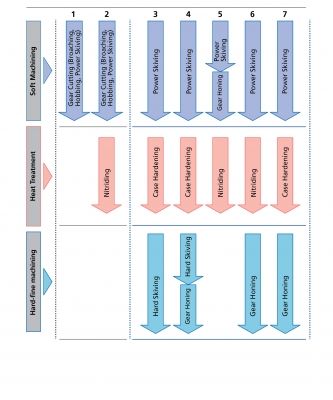

Based on a wealth of comprehensive expertise with its world-leading optimization technology known as Praewema gear honing for external gearing surfaces, the DVS gearing specialist has now refined this technology even further for the hard-fine machining of internal gearings. Supplemented by the use of the highly productive Power Skiving technology together with the possible integration of additional machining steps such as deburring, Praewema now offers an integrated package for high-precision soft and hard-fine machining of the simple planetary set - in other words, now also for inner-toothed ring gears as well as outer-toothed planetary and sun gears.

While in the past inner-toothed ring gears were not expected to reach the same high quality standards as outer-toothed planetary and sun gears, things have changed as a result of current powertrain developments. There were two reasons for the lower quality standards in the past. Tooth root bearing capacity is less critical than in planetary and sun gears due to more favorable geometrical conditions, and until recently, suitable highly developed machining technologies were simply not available due to comparatively small batch sizes of rings gears.

Up to now, manufacturers have enhanced the performance and NVH behavior of planetary gear trains almost exclusively through continuous improvements to the machining quality of planetary and sun gears with a sequence of both soft and hard-fine machining processes. These parts therefore offer high gearing qualities and strength values and allow for a large number of toothing corrections. By contrast, the inner toothing of ring gears typically made of tempering steel is usually just soft machined with no additional heat treatment as a rule after the gearing is finished. The result: limited correction possibilities and average strength values and toothing qualities, with a negative impact on wear and noise behavior and thus on the functional efficiency of the powertrain.