Feel the Burn

Heat Treat 2023 is right around the corner

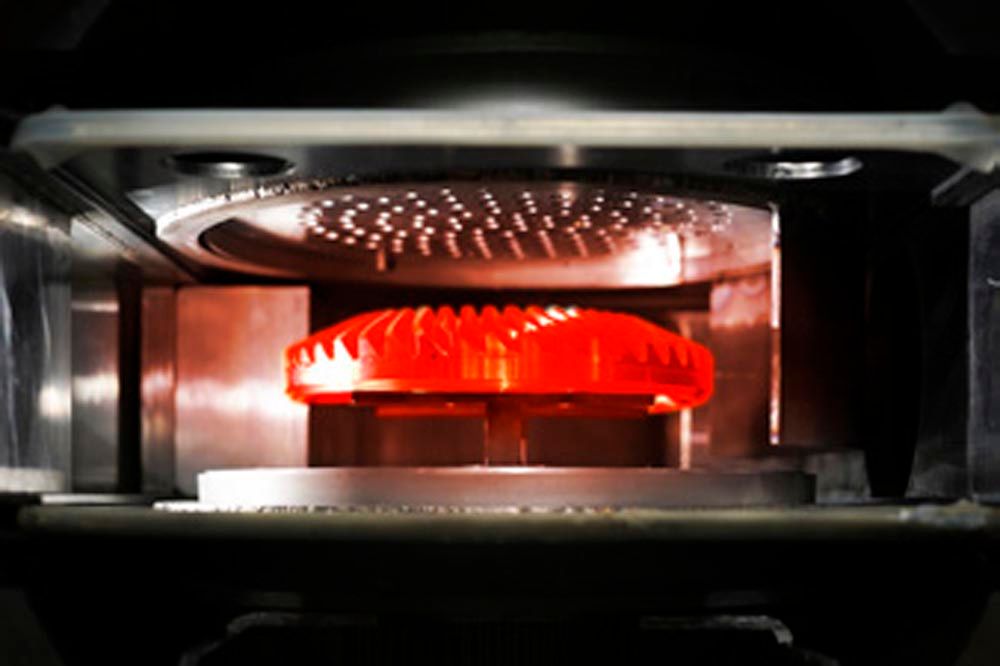

Credit: SECO/Vacuum

Heat Treat 2023 is the Heat Treating Society’s 32nd conference and expo for heat treating professionals featuring three days of face-to-face networking opportunities with approximately 200 heat treat exhibitors/companies. All the top heat-treating companies will offer the latest research and industry insights during more than 100 technical programs. This year’s show includes a VIP-guided industry tour, as well as student/emerging professionals initiatives, including free college student registration, Fluxtrol Student Research Competition, and the ASM Heat Treating Society Strong Bar Student Competition. Heat Treat 2023 is colocated with Motion + Power Technology Expo 2023 with access to additional exhibitors. The event takes place October 17–19, 2023 at Huntington Place in Detroit.

The largest of its kind in North America, the Heat Treat Conference and Expo bridges the gap between research with industry—bringing together heat-treating professionals, materials experts, global innovators, researchers, influencers, and decision-makers from around the globe. Below are a few booth previews along with a sidebar featuring some select networking and educational opportunities to look out for.

Networking and Educational OpportunitiesThe show features 100+ technical presentations and networking opportunities —(please note that details and times are subject to change)— including the following: |

Tuesday, October 17 7:00 am–9:00 amASM Women in EngineeringBreakfast (Joint with IMAT and AGMA)9:00 am–10:00 amApplied Technology / Processesand Applications: EnergyConsumption and EfficiencySession Chair: Mr. Dennis BeauchesneAtmosphere Technology andSurface Engineering ISession Chair: Prof. Mei YangMicrostructural Development /Characterization ISession Chair: Prof. Robert L. Cryderman10:30 am–11:30 amApplied Technology / Processesand Applications: Quality ControlMicrostructural Development /Characterization IISession Chair: Prof. Robert L. Cryderman1:00 pm–1:40 pmNew Trends in Global HeatTreating1:00 pm–2:20 pm“Green” Heat Treating / Low Carbon I“Green” Heat Treating / Low Carbon IIVacuum Processes and Technology2:30 pm-4:30 pmKeynote, Dr. Stefanie Tompkins,Defense Advanced ResearchProjects Agency (DARPA)4:00 PM–5:30 PMFLUXTROL STUDENTRESEARCH COMPETITION—PHASE 1—POSTERPRESENTATIONSHTS STRONG BAR STUDENTCOMPETITION—PHASE 1—POSTER PRESENTATIONSSession Chair: Mr. Robert C. Goldstein6:00 pm–9:30 pmASM ANNUAL AWARDSRECEPTION AND BANQUET(Marriott)9:30 pm–11:00 pmASM PRESIDENT’S RECEPTION(Marriott) | Wednesday, October 18 9:15 am–10:00 amKeynote, Dr. Iver Anderson,FASM, Ames Laboratory presents“Heat Treatment Effects on Sinteringof Highly Grain-refined Dy-free Nd-Fe-B Anisotropic Magnets”10:30 am–11:30 amFLUXTROL STUDENTRESEARCH COMPETITION—PHASE 2—ORALPRESENTATIONSSession Chair: Mr. Robert C. Goldstein11:45 am–12:30 pmHTS STRONG BARCOMPETITION—BENDTESTING1:00 pm–2:40 pmSimulation & Modeling I:Process Simulation (CFD/FEA)Session Chair: Mr. Andrew L. Banka, P.E.1:00 pm–3:00 pmMaterials Durability /Mechanical Testing / Non-Destructive TestingSession Chair: Mr. Jason OroszResidual Stress / Panel SessionSession Chair: Dr. Lesley D. Frame3:30 pm–4:50 pmIndustry Internet of ThingsSession Chair: Ms. Trisha RouseQuenching Technologies I:High PressureSession Chair: Dr. Mohammed Maniruzzaman3:30 pm–5:10 pmHeat Treating: InductionHeat TreatingSession Chair: Mr. Robert J. Madeira,President6:00 pm–9:00 pmNetworking Event at theWaterview Loft | Thursday, October 19 9:15 am–10:00 amKeynote, Dr. Marvin Barnes,NASA presents“Ordinary Materials, ExtraordinaryApplications”10:30 am–12:10 pmAtmosphere Technologyand Surface Engineering II:Nitriding and CleaningSession Chair: Dr. Olga K. RowanQuenching Technologies IISession Chair: Mr. David A GuisbertSimulation & Modeling II:Process Simulation (CFD/FEA)Session Chair: Mr. Stefan Habean |

SECO/Vacuum—Booth 2101

At the ASM Heat Treat Show, SECO/Vacuum will feature technologies for “the future of heat treating”:

Vector Single-Chamber High-Pressure Gas Quench Vacuum Furnace

Vector is SECO/Vacuum’s single-chamber gas quenching vacuum furnace using high-pressure quench (2 to 25 bar) which can be applied to a wide variety of heat-treating processes and applications. It provides important capabilities for producing high uniformity in heat-treated parts, high consistency in workloads, and high speeds in batch processing with low consumption of power and process gases.

Casemaster Evolution Multichamber Gas or Oil Quench Vacuum Furnace

SECO/Vacuum offers two configurations of its CaseMaster Evolution. The two-chamber furnace, called D type, is a dual-chamber furnace with one chamber for vacuum heat processing and a second chamber for oil or gas quenching. The three-chamber furnace, called T type, provides the same chambers as the D type plus a third pre-heating (and/or pre-oxidation chamber) which increases productivity through semi-continuous batch processing. In the three-chamber approach SECO/Vacuum’s PreNitLPC process can be added for even higher productivity.