Gear Expo Preview: Star SU Booth 901

Star SU plans to expand its role as an integration solutions expert for machine tools including workpiece holding, perishable tooling, gaging and automation, according to David Goodfellow, president, Star SU LLC. In Indianapolis, Star SU will feature the Bourn & Koch 100 H horizontal hobbing machine at Gear Expo. The Bourn & Koch 100 H can hob splines and geared shafts up to 100 mm in diameter. Mount tools in combinations to cut different gearings on one workpiece or to mill keyways and slots in one tool setup without reclamping. Since the chip conveyor is located directly under the tool spindle, chips are evacuated immediately from the machine to avoid any thermal distortions. In addition, the 100 H can be ordered with automation for machining larger lots. The extended version of the 100 H with a NUM Flexium control can accommodate a workpiece up to 916 mm (36") long and 126 mm (5") in diameter.

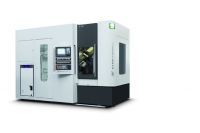

The Samputensili G 250 has been especially developed for very low cycle times and for top-quality and efficient mass production of gears with outside diameters up to 250 mm and shafts with lengths up to 500 mm. The secret behind the machine’s efficiency is the dual work spindle concept, which eliminates non-productive auxiliary times almost completely. By means of the dual work spindles, the loading/unloading process of a workpiece is carried out in masked time, while simultaneously the manufacturing process proceeds on another workpiece. The G 250 can equally use form and worm grinding wheels, both in ceramic and in electroplated CBN. A video presentation of the G 250 will be available at the Star SU booth.