Precision measuring centers for gear

measurement, as shown in Figure 2, provide

the appropriate prerequisites:

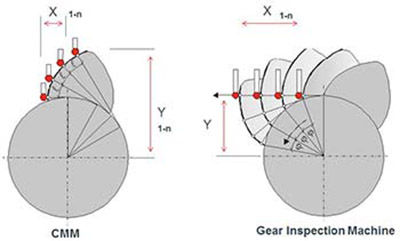

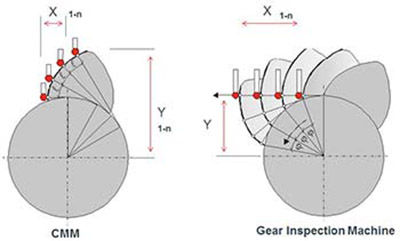

Gearing measuring centers as shown

in Figure 2 also have the advantage that

measured value recording takes place

for cylindrical gears with involute gearing

according to the generation principle

(Figure 4). The involute curve is generated

automatically through the coupled rotational

movement of the workpiece with

the tangential measuring axis, resulting in

stable measurement results, even in the

case of positional deviations of the probing

system due to environmental influences

in production, for example.

Figure 4 Measuring principle.

- Click image to enlarge

By contrast, profile measurement based

on polar coordinates, as is common in

general CMM, is significantly more sensitive

to positional variations.

Prerequisites for Reliable

Performance of Shop-Floor

Measurements

An important feature of shop-floor

measurement is that the operating staff

for the production equipment (hobbing

machines, grinding machines, etc.)

also carries out the gear measurements.

The purpose of the measurements is to

inspect gearing quality following a workpiece

change, for instance, or during

ongoing production.

This means that the measurements are

not carried out by trained measurement

technicians, but rather by machine operators.

Additional measures are therefore

required to perform reliable, accurate

measurements.

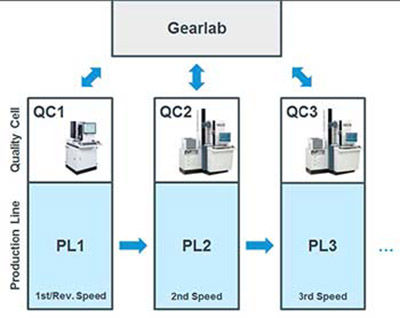

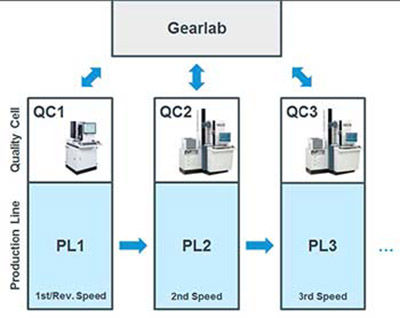

Figure 5 shows the layout of a shop

floor with an integrated measuring station.

There are production lines (PL1–

PLn) for the individual components of a

transmission. Each production line has

its own test station (QC1–QCn). Each

test station is also networked with a central

measuring chamber. In this central

measuring chamber, prototype measurements

are carried out, and the individual

measurement programs that will subsequently

be transferred to the test stations

in production are created. The measuring

results recorded on the shop floor are

then transferred back to the measuring

chamber, where approval will be granted

or additional evaluations, such as statistical

analyses, will be carried out.

Figure 5 Layout of a gear component factory.

- Click image to enlarge

The objective is to enable the operator

to carry out the necessary measurements

on the shop-floor measuring machine

with as much ease and reliability as possible.

This relies in part on a simple, precise

workpiece fixture. A workpiece fixture

between centers lends itself well for shafttype

workpieces. For disk-shaped workpieces

and internal gearing, a chuck is the

fixture of choice. The chuck should be

designed so that few or no exchange parts

are required for different workpieces.

An automatic probe change rack on the

measuring devices is recommended when

using different probe elements for gearing

measurement. The probe change rack

enables all necessary probe elements to

be calibrated automatically at fixed intervals

(once per day or once per shift).

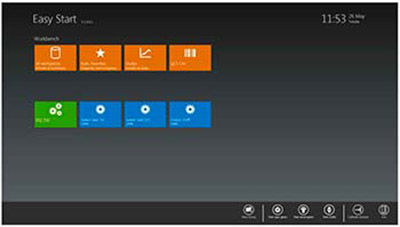

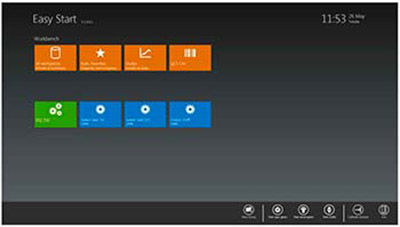

The individual measurement programs

are accessed by means of a simply

designed graphical user interface, as

shown in Figure 6. All measurement programs

needed for a measuring station or

specific transmission components can be

programmed into this page as on a desktop

and launched as necessary.

Figure 6 Software HMI.

- Click image to enlarge

The system also includes measurement

program retrieval via a barcode scanner.

As already mentioned at the out-set, workpiece cleanliness is important

for obtaining accurate, reliable measuring

results. The measuring station should

therefore also have a workpiece washing

station nearby. The advantage of a coldwater

washing station is that the workpieces

are not warmed, thus obviating temperature-

induced measurement variations.

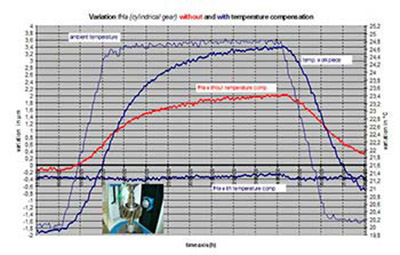

Workpiece temperature is generally a

consideration for accurate measurements.

In gear measurement, certain measurement

parameters are insensitive to temperature,

while others respond with

greater sensitivity.

Due to the relatively small gearing

dimensions in the automotive industry,

temperature-induced changes in length

are relevant here only for certain parameters.

The relative test parameters for profile,

tooth trace, pitch and concentricity

measurements are rather insensitive.

Large, temperature-induced variations

can occur, however, when determining

tooth thickness or dimension over balls,

when the temperature of the workpieces

deviates from the reference temperature

of 68°F. In this case, a measuring device

with workpiece temperature probes is

used for compensation.

Maintenance and Calibration of

Shop-Floor Measuring Devices

Use of a measuring device on the shop

floor generally requires slightly more

maintenance and calibration.

Fixed procedures should therefore be

specified for individual measuring stations

as follows, for example:

Daily maintenance

- Inspection of traversing paths of measuring

device axes

- Monitoring of the device for unusual

noises during the measuring procedure

- Calibration of the probe elements used

(once per shift)

Weekly maintenance

- Inspection of the measuring device for

measuring accuracy by means of comparative

measurements against the reference

standard

- Compressed air supply check

- Cleaning of workpiece fixture components

Quarterly maintenance

- Replacement of filter elements in the

control cabinet

- Emptying of condensate from the compressed

air service unit

Annual maintenance

- Inspection of the measuring device by

an OEM service employee

As regards measuring accuracy, a comparative

measurement against a reference

standard across all measuring devices is

also needed at regular intervals.

Of course, the manner in which the

operating staff handles the measuring

device is an essential factor in maintenance

expenses and in ensuring consistent

measuring accuracy. It is certainly an

advantage if staff members receive basic

training in the proper handling of highprecision

measuring devices.

Summary

Quality monitoring of gearing workpieces

carried out on the shop floor offers a

number of benefits:

- Variations in measuring results are

identified more quickly, thereby reducing

the number of rejects.

- When changing tools on the machining

equipment, the operator can immediately

verify the settings by measuring

the workpiece and can make any necessary

corrections without lengthy production

breakdowns.

- The machine operator is thus directly

involved in the quality assurance process

and consequently performs with a

greater overall focus on quality.

- The number of complicated measuring

chambers can be reduced.

To successfully introduce quality assurance

on the shop floor, however, appropriate

prerequisites must be in place.

Careful planning is absolutely necessary.

Exchanges of experience with other

companies that have successfully introduced

this production structure can certainly

be helpful.

About Author

Dipl.-Ing. Günter

Mikoleizig currently

heads the Product

Management and

Application Engineering-

Department for gear

inspection machines at

the Klingelnberg GmbH,

Germany. For more than 30 years he is working

in the field of gear inspection technology and

he is well experienced with the design and

development of inspection machines and the

product management. He developed a product

line of inspection machines for all kind of gears

and other related parts with small dimensions

up to very big sizes. Mikoleizig presented

papers about gear inspection worldwide

and is also an active member of national and

international standardization committees.