A mapping is used to transform the rack coordinates (x,r, yr) to

polar gear tooth coordinates (uc, vc). This transformation can be

envisioned as wrapping a rack onto a pitch circle with the desired

pitch radius up. This transformation is the envelope of the rack as

it meshes with a circle of radius up. Depicted in Figure 5 is a rack

being wrapped onto a pitch circle with radius up.

Figure 5 Transforming or “wrapping” the rack onto the desired

pitch circle.

- Click image to enlarge

Cylindroidal Coordinates

A system of curvilinear coordinates is used to parameterize

the kinematic geometry of motion transmission between skew

axes. These curvilinear coordinates are based upon the cylindroid

determined by the two axes of rotation, $i and $o, and are

referred to as cylindroidal coordinates. Cylindroidal coordinates

consist of families of pitch, transverse, and axial surfaces. Pitch

surfaces are specified in terms of the axes of rotation $i and $o. $i

is the input axis (pinion) of rotation and $o is the output (ring)

axis of rotation. Pitch surfaces are a family of ruled surfaces, and

axodes are the unique pitch surfaces that depend upon a particular

I/O relationship. For this reason, the pitch surfaces are

referred to as the reference pitch surfaces.

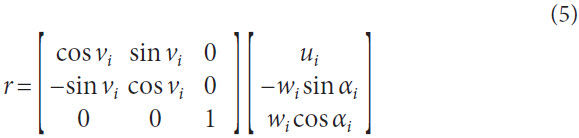

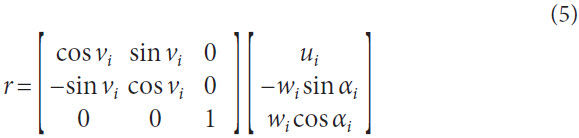

A system of curvilinear coordinates (u, v, w) is used to

describe spiral bevel and hypoid gears. The coordinates (u, v, w)

used to parameterize these families of pitch, transverse, and

axial surfaces are formulated using the cylindroid defined by

the input and output axes of rotation. A design methodology

for spatial gearing analogous to cylindrical gearing begins with

the equivalence of friction cylinders. Figure 6 shows two such

wheels along with candidate generators. The I/O relationship g

defines which generator of the cylindroid is used to parameterize

the input and output friction wheels. These generalized friction

surfaces are two ruled surfaces determined by the instantaneous

generator. The transmission of motion between the

two generally disposed axes $i and $o via two friction surfaces

requires knowledge of the instantaneous generator. The location

of the instantaneous generator relative to the two axes $i and $o

depends upon:

- Distance E along the common perpendicular to axes of rotation

$i and $o

- Angle Σ between axes of rotation $i and $o

- Magnitude of the I/O relationship g

Figure 6 Two friction wheels for motion transmission between skew

axes.

- Click image to enlarge

Motion transmission between the two skew axes $i and $o

results in a combination of an angular displacement about the

instantaneous generator and a linear displacement along the

instantaneous generator. The ratio h of linear displacement to

that of the angular displacement is the pitch associated with

the instantaneous generator. The pitch hisa associated with the

instantaneous generator is the instantaneous screw axis, or ISA.

A transverse surface is an infinitesimally thin surface used to

parameterize conjugate surfaces for direct contact between two

axes. Candidate generators for the reference pitch surface are

determined by the generators of the cylindroid ($i; $o). Given g,

each position angular vi and axial position wi define a unique

point p in space. Allowing g to vary from -∞ to ∞, the point p

traces a curve in space. Another value of the input position vi

defines the same cylindroid. There is an angular displacement

between these two cylindroids. It is this two-parameter loci of

points p that compose the transverse surface. The Cartesian

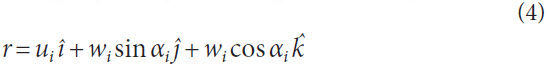

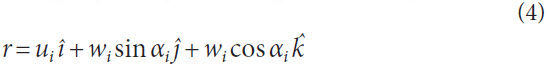

coordinates r for the single point p on the generator $ai are:

Rotating the above curve r about the zi-axis an amount vi

leads to:

Where

u radius of hyperboloidal pitch surface (at throat)

v angular position of generator on pitch surface

w axial position along generator of pitch surface

α angle between generator and central axis of pitch surface

The axial surface provides the relationship between successive

transverse surfaces. For each value of vi, the axial surface

is the loci of generators determined by g, where -∞ < g < ∞. The

curves defined by holding two of the three parameters u, v, and

w constant are coordinate curves. Two parameters used to define a surface are the curvilinear coordinates

of that surface: the pitch surface by vi and

wi (ui = constant), the transverse surface by

ui and vi (wi = constant), and the axial surface

by ui and wi (vi = constant). Depicted

in Figure 7 are the pitch, transverse, and

axial surfaces determined using cylindroidal

coordinates (ui, vi, wi). Three surfaces

are used to describe the geometry of gear

elements.

Figure 7 Pitch, transverse, and axial surface for uniform motion transmission..

- Click image to enlarge

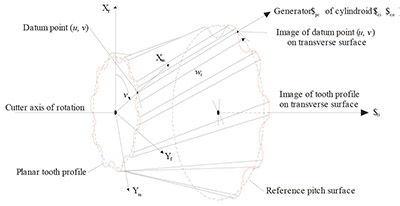

The curvilinear coordinates (uc, vc, wc)

used to parameterize the proposed cutters

are defined by introducing a cutter-cylindroid

($ci; $co). This enables cutters to be

designed in pairs analogous to the design

of gear pairs where two cutters are proposed

for the fabrication of spiral toothed

bodies. One feature of the cutter cylindroid

is that expressions involving the cutters

are obtained by simply changing the

trailing subscripts in existing expressions

involving the input gear from “i” to “c”.

In order to minimize the notation necessary

to distinguish the input cutter from

the output cutter, only a “c” subscript is

used with no indication as to whether it

is the input cutter or the output cutter.

Implicit in the cutter designation will be an “o” subscript when

describing the input gear. Likewise, when describing the output

gear body, it will be assumed that associated with the cutter is an

“i” subscript to identify that it designates the input cutter. The

above reasoning is that two toothed bodies in mesh involve an

input and an output body. The three possibilities being:

- Input gear body and an output gear body

- Input gear body and an output cutter

- Input cutter and an output gear body

The two twist axes $ci and $co are the two screws of zero

pitch on the cutter cylindroid ($ci; $co). The generators $pc are

determined by also introducing a cutter I/O relationship gc.

Expressions for the radius uac and the angle αac are identical to

those for uai and αai, except E, Σ, and g are replaced by Ec, Σc, and

gc, respectively.

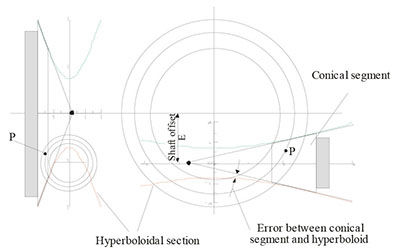

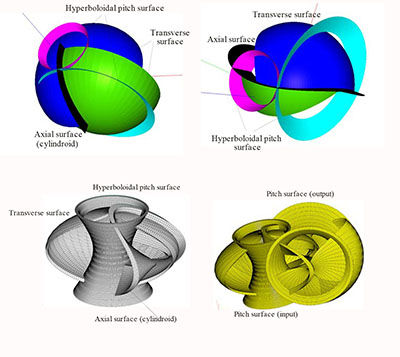

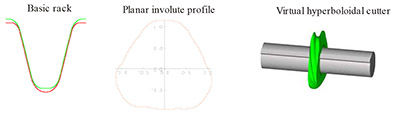

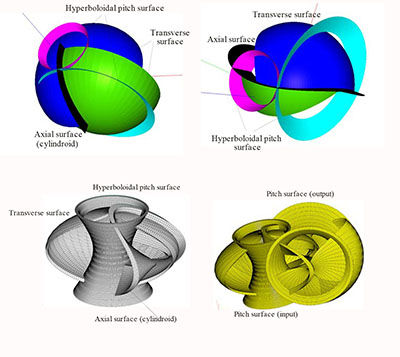

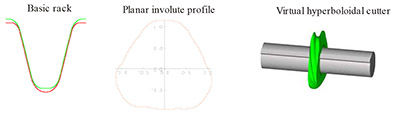

Hyperboloidal Cutter Coordinates

General hyperboloidal cutter elements are defined by introducing

a mapping within a system of cylindroidal coordinates.

The purpose of this mapping is to utilize knowledge of conjugate

curves for motion transmission between parallel axes and

apply it to conjugate surfaces for motion transmission between

skew axes. A visual representation of this mapping is shown in

Figure 8. There exists a single generator within a system of curvilinear

coordinates as part of the cylindroid ($i; $o) that is coincident

with each point (u, v). For an arbitrary axial position wc

along this generator, a transverse surface exists. Each value (u, v)

defines a different generator. The distance wc along each of these

generators from (u, v) to a single transverse surface is constant.

It is the image of these datum points (u, v) upon a given transverse

surface that defines the mapping. This mapping is valid for

Figure 8 Mapping of planar gear profile onto transverse surface.

- Click image to enlarge

any type of cutter tooth profile (viz., involute, cyclodial, circulararc,

and convuloid).

The planar coordinates (u, v) used to define conjugate curves

are polar coordinates where v is an angular position about the

“z-axis” and u is the corresponding radius. Use of coordinates

(u, v) to specify conjugate curves in the plane are fashioned

such that conjugate surfaces in space are obtained using the cylindroidal

coordinates (uc, vc, wc). This is achieved by assigning

a value to the axial position wc and defining uc ≡ uc and vc ≡ v.

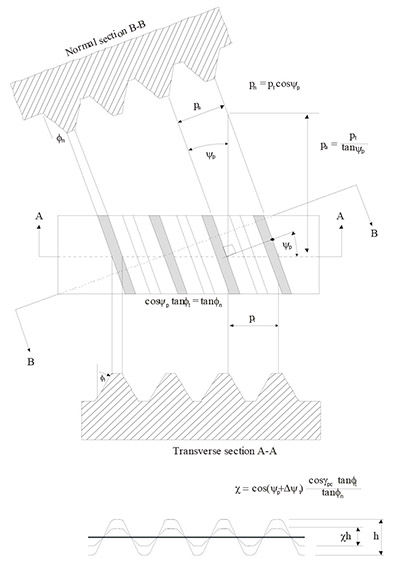

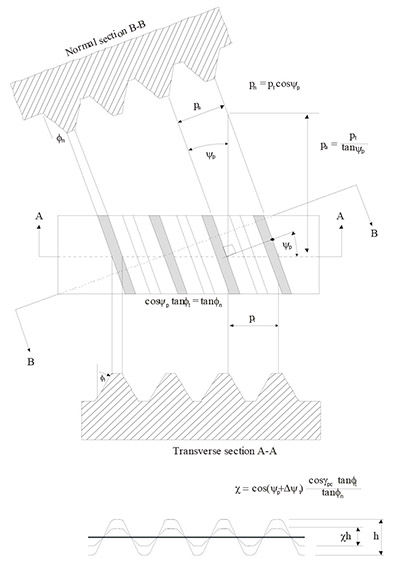

Cutter coordinates must be “scaled” to satisfy the appropriate

transverse pitches. Such scaling is illustrated in Figure 9 and is

obtained by recognizing that the virtual length of the striction

curve spc is the component of its length perpendicular to the

tooth. This scaling is performed prior to the “wrapping” of the

rack onto the circular disk depicted in Figure 3 and depends on

the diametral pitch. The diametral pitch Pd used to parameterize

the cutter teeth depends on the size or radius of the input and

output cutter. The x-scaling or stretch along the x-axis is shown

in Figure 9 and depends on the cone angle αpc; thus, for an arbitrary

angle vc, the corresponding parameter xr used to evaluate

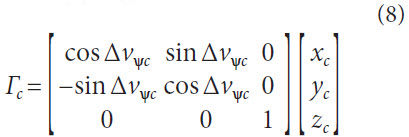

the expressions for the tooth profile becomes:

Figure 9 Scaling of tooth profile on cutter element.

- Click image to enlarge

Where

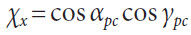

The angle apc = ypc at the throat (i.e., wc = 0). It is the diametral

pitch at the throat that is used to specify the pitch of the cutter

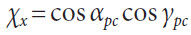

profiles. The cutter is expressed using the Cartesian coordinates

(xc, yc, zc) as follows:

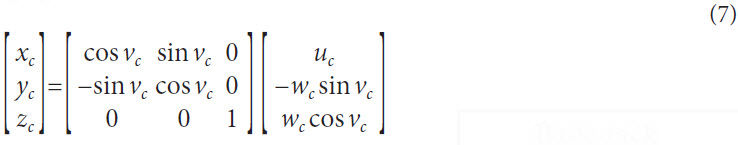

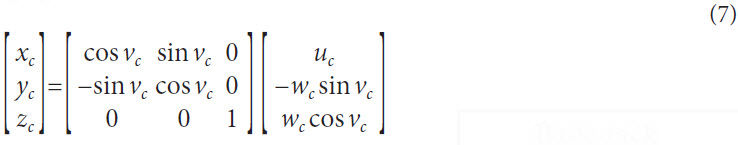

The image of the coordinates

(xc, yc, zc) upon the transverse surfaces

must account for the cutter spiral.

Consequently, a transverse angular

displacement Δvѱc is superimposed

on the mapping as follows:

The cutter spiral depends on the ratio between the axial displacement

Δwѱc and the angular displacement Δvѱc. The displacement

Δvѱc is based on a constant lead for a given transverse

surface and the spiral angles ѱc for each radii uc are different.

Note that the displacement Δvѱc is based on the lead for the reference

pitch surface and the spiral angles ѱc change for each

radius uc.

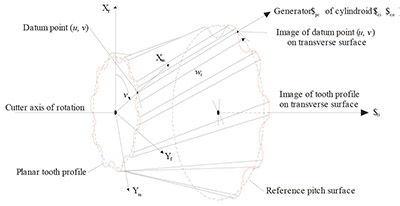

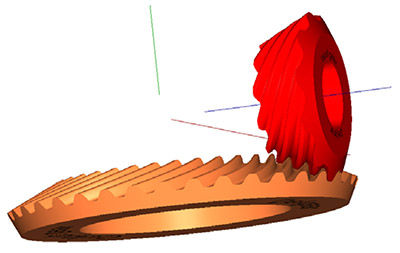

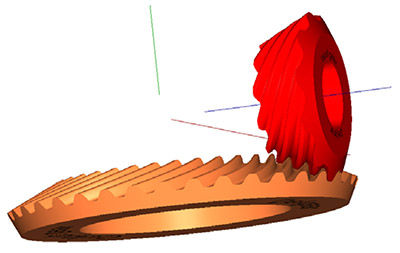

Illustrative Example

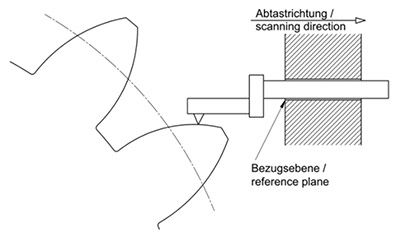

This example presents a spiral hypoid gear set for motion transmission

between skew axes using Delgear software (Ref. 16).

The shaft angle is 90° and the shaft offset is 25 mm. The speed

ratio 3.27; 11 teeth on the pinion and 36 teeth on the ring gear.

The face width is 35 mm, the axial contact ratio is 3.0 and the

nominal spiral angle is 61°. The tooth profile is a standard invo-

Figure 11 Input and output gears with involute teeth.

Figure 10 Rack, transverse profile, hyperboloidal cutter.

Figure 9 Scaling of tooth profile on cutter element.

60 GEAR TECHNOLOGY | May 2015

[www.geartechnology.com]

technical

lute tooth profile. The normal pressure angle is 20°, the transverse

contact ratio is 1.25, the addendum constant is 1.0 and the

dedendum constant is 1.2. The variable diameter cutter has three

teeth and the nominal lead angle is 10°. Figure 10 shows the rack

tooth, a transverse segment of the cutter, and a virtual model of

the cutter. The gear pair is depicted in mesh in Figure 11.

Figure 10 Rack, transverse profile, hyperboloidal cutter.

- Click image to enlarge

Figure 11 Input and output gears with involute teeth.

- Click image to enlarge

Summary

Demonstrated is the specification of involute gear teeth on hypoid

gears. This process involves the specification of a classical

involute rack, a mapping that transforms this rack to a planar

circular profile. A system of cylindroidal coordinates is used to

define hyperboloidal cutters. Another transformation is used

to map the planar circular profile to a hyperboloidal cutter with

suitable geometry for specifying general spiral bevel and hypoid

gear pairs. An example of an automotive rear differential gear

set is presented to illustrate the process.

- Shtipelman, B.A. Design and manufacture of Hypoid Gears, 1978, John Wiley

& Sons, New York.

- Stadtfeld, H.J. Handbook of Bevel and Hypoid Gears, 1993, Rochester Institute

of Technology, Rochester.

- Litvin, F.L. and A. Fuentes. Gear Geometry and Applied Theory, 2004, 2nd

Ed. Cambridge University Press, London England.

- Wu, D. and J. Luo. A Geometric Theory of Conjugate Tooth Surfaces, 1992,

World Scientific, New Jersey.

- Wang, K.L. and S.K. Ghosh. Advanced Theories of Hypoid Gears, 1994,

Elsevier, Amsterdam.

- Radzevich, S. P. Theory of Gearing: Kinematics, Geometry, and Synthesis,

2012, CRC Press, Taylor and Francis Group.

- Kapelevich, A.L. Direct Gear Design, 2013, CRC Press, Taylor and Francis

Group.

- Xiao, D.Z. and A.T. Yang. “Kinematics of Three-Dimensional Gearing,” 1989,

Mechanism and Machine Theory, Vol. 24, Issue 4, pp. 245-255.

- Figliolini, G., H. Stachel and J. Angeles. “The Computational Fundamentals

of Spatial Cycloidal Gearing,” 2009 Proceedings of 5th International Workshop

on Computational Kinematics, Dusseldorf Germany, May, pp. 375-384,

Springer.

- Hestenes, D. “Old Wine in New Bottles: a New Algebraic Framework for

Computational Geometry,” 2001, Geometric Algebra with Applications in

Science and Engineering, E. Bayro-Corrochano and G. Sobcyzk, Eds. pp.

1-16, Birkhauser, Boston, MA.

- Ito, N. and K. Takahashi. “Extension of the Euler-Savary Equation to

Hypoid Gears,” 1999, MSME Mechanical Systems, Machine Elements, and

Manufacturing, Series C, Vol. 42, No. 1.

- Grill, J. “Calculating and Optimizing of Grinding Wheels for Manufacturing

Grounded Gear Hobs,” 1999, 4th World Congress on Gearing and Power

Transmission, Paris France, Mar. 16-18, pp. 1661-1671.

- Baozhen, L., H. Lowe and W. Xumwei. “A New Approach to the Theory

of Gearing Using Modern Differential Geometry,” 2013, International

Conference on Gears, Munich Germany, Oct. 7-9, pp. 1379-1390.

- Phillips, J.R. Geared Spatial Involute Gearing, 2003, Springer, Berlin.

- Dooner, D.B. Kinematic Geometry of Gearing, 2012, 2nd Ed., Wiley, London.

- http:\\www.delgear.com.

This paper was originally presented at the 2014 International Gear Conference, Lyon Villeurbanne, France. It is republished here with the author’s permission.

About Author

David Dooner graduated from the University of Florida

in 1991. Afterwards, he was a visiting scientist with the

Russian Academy of Sciences in Moscow and joined

the University of Puerto Rico-Mayaguez (UPRM) in 1994.

Since joining UPRM, he has been involved with teaching,

services, and research. His research focus involves a

mathematical approach for the design and manufacture

of general hypoid gear pairs. He currently teaches

mechanism design, machine design, and senior capstone design. He is

currently a member ASME, ASEE, and AGMA.