Micro Waterjet Bridges Gap Between EDM and Micro Laser

Cutting narrow incisions with ultra-high precision in high density materials using waterjet technology requires a specific waterjet cutting process: The Fine Abrasive Waterjet process (FAWJ). The first FAWJ cutting head was developed by Water Jet Sweden in 2008.

Fine Abrasive Waterjet bridges the gap

Waterjet cutting is a common method for processing parts in high density materials such as aluminum, stainless steel, titanium and carbon composites. The FAWJ cutting process bridges the gap between micro laser and EDM cutting and brings water jet cutting into the field of micro part processing.

To enable such levels of precision you need two things: (1) a cutting head and cutting process for FAWJ cutting, and (2) a machine built for extreme accuracy. The NCM 10 Micro from Water Jet Sweden fulfils both of those requirements.

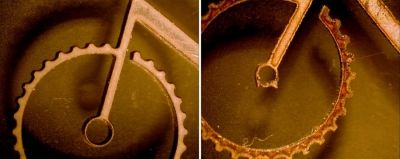

FAWJ cutting process for 0.2 mm incisions

The first micro waterjet cutting head was developed by Water Jet Sweden in 2008. It is a high precision cutting tool producing one of the most precise abrasive water jets in the world. The unique cutting head enables an abrasive jet diameter down to 0.2 mm. The FAWJ cutting process requires very fine abrasives of 230-240 mesh and a special CNC controlled dosage abrasive feeder.