Dr. Jürgen Greiner is the development

head of passenger car transmissions for

ZF. And while he agrees, “in principle,”

that “transmissions with higher transmission-

ratio spreads and more gears

with smaller gear steps… reduce fuel

consumption,” it is also his position that

, “Generally, the number of gears is not a

primary feature of a transmission for ZF.

When it comes to developing transmissions,

the relevant factor is not the number

of gears but the spread of gear ratios

and drivability that plays an important

role; the number of gears is simply the

result. Only with excellent shift quality

is a high number of gears perceived

as comfortable — with no tractive force

interruption.”

But of course the need for speed will

always exist for drivers of all stripes. As

Stadtfeld points out, “Although efficiency

is very important today, the higher

number of gears also manages an immediate

adjustment of the ratio to a point

where the engine is capable of the highest

possible power delivery in order to realize fast acceleration.”

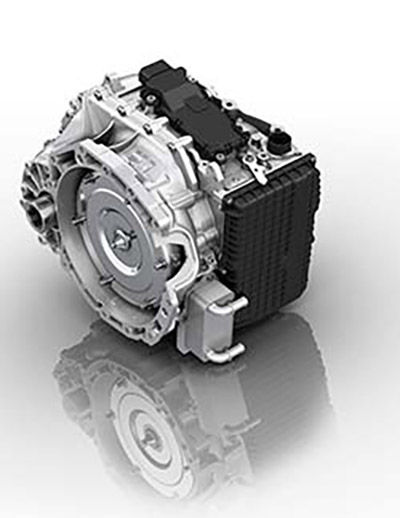

Premiere in the BMW 5 Series: The 520d is the first

production model to come off the production line with the

new ZF 8HP transmission generation (Photo courtesy ZF).

- Click image to enlarge

By the way — just what kind of transmissions

are we (or should be) talking

about? For our general purposes,

two — 1) the best-known-in-the-U.S.

automatic transmission (AT); and 2)

the continuously variable transmission

(CVT), well known and used in Japan.

Though others exist, the talk is mainly

about ATs vs. CVTs, along with some

“hybrid-type” transmission talk as well.

ZF’s Greiner begins some transmission

anatomy for us:

“An automatic transmission (AT) comprises

several (planetary) gearsets, in different

quantities and combinations. For

example, there are four planetary gearsets

in the new ZF 9-speed automatic

transmission. The various ratios — i.e.,

gears — of the planetary gearset are generated

by fixing one gear and by connecting

and disconnecting various

shafts. This is done using so-called shift

elements (friction shift elements such

as multi-disk clutches or multi-disk

brakes), and constant-mesh elements. In

the new 9-speed automatic transmission,

there are a total of 6 shift elements, two

sets of multi-disk clutches and brakes, as

well as two dog clutches — a first in passenger

car automatic transmissions.

“Most types of transmissions are

stepped transmissions. This means they

have a specific number of gear pairs

that offer a fixed number of gear ratios,

depending on the design. The power

range of the combustion engine cannot

be fully harnessed, however, with this

limited number of transmission stages.

In contrast, a continuously variable transmission

(CVT) is, as the name suggests, a

transmission that can change seamlessly

through an infinite number of effective

gear ratios. This is particularly beneficial

for the characteristics of a combustion

engine. Along the entire engine performance

graph, operation can be adjusted

with a continuously variable transmission

ratio to achieve optimum fuel

consumption or fastest acceleration on

request.”

But, as Greiner then adds, “Unlimited

speeds, like in the case of the CVT,

reduce efficiency since you need energy

for the transmission of power. The

system-related lower efficiency; limitations

when transmitting torques; the

maximum transmission ratio range to be

achieved; and the higher weight reveal

the physical limits of (CVT) design. The

CVT is the most demanding and most

expensive (to manufacture).”

“A ‘conventional’ gear transmission is

really region-specific,” Mack points out.

“In, say, North America, it (transmission)

would be a torque converter, planetary

automatic. In many other parts of

the world (e.g., most of Europe) it would

likely be a manual transmission.

“There are also many variants of

‘hybrid transmissions’ under consideration,”

says Mack. “Most current

hybrids in passenger cars today are electric

hybrids. With many possible variants

— from an inline electric motor

on the transmission input to the wellknown

input split transmission as used

in the Ford Escape, which has two electric

motors with an internal combustion

engine, with one motor operating across a planetary gearset — creating an (IVT).”

But, “Maybe the name ‘conventional’

automatic transmission becomes outdated,”

suggests Stadtfeld. “In the U.S.,

from the 1950s until the early 2000s, these

kinds of transmissions with three and later

mainly four-speeds were most popular.

Then even more speeds were introduced

in conventional ATs. In addition, CVTs

and double-clutch transmissions (DCTs)

had been introduced. For example, the

market share of CVTs in 2014 is around

19% of all automatic transmissions

(Source: EPA Technology Trends 2014).

“The gears transmit the power via

positive-form engagement, whereas the

clutches transmit the power via friction

contact. Nevertheless, due to the intelligent

use of other positive-engagement

units like dog couplings, lamellae brakes

can be replaced, helping to reduce friction

losses. An additional standard element

to improve the efficiency is the

lock-up clutch to bypass the torque

converter in situations when it is not

required and would only lower the efficiency

due to slippage.

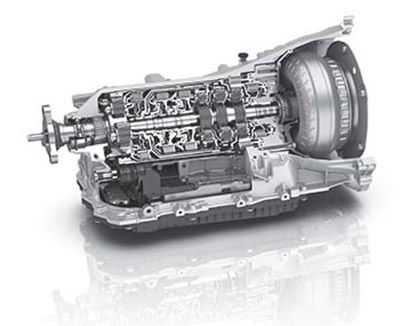

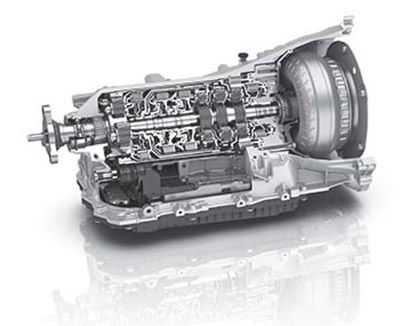

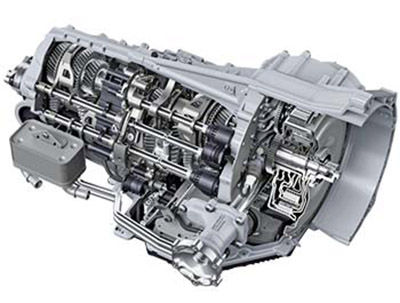

ZF’s enhanced second-generation, eight-speed automatic

transmission (8HP) is designed to provide effective support for

automotive manufacturers in meeting the ever-stricter legal CO2

standards — and in a cost-effective manner in combination with

conventional or hybridized drives (Photo courtesy ZF).

- Click image to enlarge

“CVTs require, next to their variable

transmission unit,

either a lamellae

clutch or a torque

converter as a startup-

element. The

power is then transmitted

to one of

the variable coneshaped

pulleys.

This pulley transmits

the power via

a metal push belt to

the other pulley that

transmits the power

to the output shaft.

The required ratio

is generated by an

adverse variation

of the two pulley

diameters. The power is transmitted via

friction contact. For this reason the pressing

forces between the pulleys and the

belt need to be high enough to avoid slippage

at the required torque. This leads in

general to a high power consumption of

the internal hydraulic system and the friction

between the belt joints, lowering the

efficiency of the system.”

Well what then of the ballyhooed (gasand-

electric-powered) hybrids?

Says Stadtfeld, “Today there is a large

diversity, with increasing numbers of

automatic transmissions based on different

concepts. The tendency is that

the market share of conventional automatic

transmissions is going to decrease

in certain segments, like medium and smaller vehicle classes, and the diversity

increases. Other forms will appear — like

DCTs, or more exotic transmissions like

IVTs — and will deliver the torque and

efficiency requirements while having

lower costs and acceptable comfort.”

Is it harder to design these new transmissions

for Cadillacs than Fiats, for

example?

As Mack explains it, “The role of the

transmission is to most effectively integrate

the requirements of the vehicle to

the characteristics of the engine. It is

really all about transferring the power

from the internal combustion engine

to the wheels. The transmission ratio

essentially defines the speed at which

the engine operates, and we need to get

the engine into its most efficient zone

of operation. If the engine torque is

reduced and the vehicle requirements

remain the same, the transmission will

need to be “longer lever” — i.e. more

ratio coverage. We also need smooth

transitions from one discrete ratio to the

next and sufficient refinement. The level

of challenge in designing for a powerfulluxury

vehicle or a smaller segment is

very much the same.”

Greiner believes that, “In principle, it

makes sense to use transmissions with

higher transmission-ratio spreads and

more gears with smaller gear steps to

reduce fuel consumption.”

But with increasing ratios come, it

would seem, greater complexity.

Greiner responds that, “If we could fit

even more gear steps in the space currently

available, it is initially technically

possible for the number of gears to reach

double-digit figures. Gradually, we are

reaching the boundaries of what is sensible.

For example, the transmission’s

spread of gear ratios is now so wide that

engines are at the limit of being drivable.

Electric motors and combustion engines

need to be combined to work together

in harmony. Integrated electronics as

well as an intelligent drive management

embedded in driver assistance functions

are necessary to achieve this.”

While it is hoped the above back-andforth

has brought some clarity to the

discussion of newest-technology, CO2-

friendly automobile transmissions, the

question arises: If there were no air pollution,

would we even be having this discussion,

or is this transmissions evolution

simply a marketplace inevitability?

What a stupid question to ask engineers.

“In our nature as humans, essentially

we always want to improve upon the

status-quo, and strive for a competitive

advantage,” says Mack. “The competitive

marketplace drives the need for more

features, more performance, driving ‘fun’

and, of course, higher value. The government

regulations are merely accelerating

the rate of development with certain criteria

in mind. The drive for lower CO2

emissions or higher MPG can also be

viewed as wasting less energy. Over the

prior century we have constantly evolved

the science of transmission engineering

with a common goal — to increase efficiency,

transfer more of the torque, and

waste less.”

“Pollution is only one aspect why we

have this transmission evolution,” says

Stadtfeld. “Besides the cost of gasoline

for the consumer, also the production of

gasoline is connected to certain environmental

implications. Vehicles with auto-matic transmissions newer than model

year (MY) 2010 already consume, on

average, the same or less amount of gasoline

than their manual counterparts,

while offering other advantages. For

example, current and future automated

driving systems would be impossible

with manual transmissions. In addition,

more gears deliver a smoother driving

experience with better capability to

use the engine’s power. But more gears

require the transmission to be automatic

because only a very few people would

accept shifting through 9 or more gears

in a car while constantly watching the

optimal shift timing to achieve smooth

and efficient driving.” Here’s one last big

question: Which of the new technologies

has the best chance of replacing “conventional”

transmissions? Is there a logical

endgame?

It depends. Good luck defining “conventional,”

for instance, when describing

transmissions.

“This is not an easy question to

answer, and I wish I had a crystal ball,”

Mack admits. “The definition of a ‘conventional

transmission’ is not standing

still, and is regionally defined. There are

two primary factors to consider. First,

from a propulsion system viewpoint, we

need to attain an optimum system efficiency,

which includes using the transmission

to “move” the operating point

of the engine into its sweet-spot; and

secondly, the transmission itself, regardless

of architecture chosen, will evolve

to constantly improve the state of art.

Gears have been and will likely remain

the most efficient method of transferring

torque. Amongst the ‘new transmissions’

we would include DCTs and

many hybrid electric variants. With

recent developments in some CVT technologies,

there may be a challenge on

the horizon. There are multiple technologies

with promise and the potential

means to effectively achieve the goals.

We continue to see an evolving mix

of technologies — with no single winner.

Consumer demand will also play a

role in the proliferation of technologies

on our roads. Pros and cons are unfortunately

not based merely on technical

merit, but also on many other market

drivers; e.g. — legislation, consumer

acceptance, cost, manufacturing investment,

etc.”

“We see new focal points” Greiner

allows — if not so much for gears — “in

the field of power electronics, the intelligent

driving strategy, the development

of ever improved electric motors, or

the integration of the electric drive in

the installation space which before was reserved exclusively for the transmission.

The further you go in the direction of

hybrids or electric vehicles in the future,

the less gears will be needed, dependent

on to what extent combustion engines

make up the drive. Electric motors and

combustion engines need to be combined

to work together in harmony.”

We had to ask for predictions of what

kind of transmission will be used in the

first truly popular car with an all-electric

engine? Will torque control still rule?

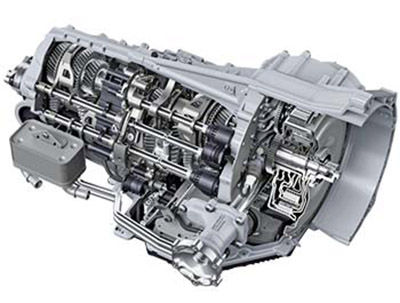

ZF’s 7-speed DCT. Direct-drive and rapid

gear changes with no interrupting shear

force make for very sporty driving. This

DCT also achieves better fuel economy

than that of a manual transmission thanks

to enhanced fuel engineering.

- Click image to enlarge

Gleason’s Strunk: “Due to the significant

difference in power output characteristics

between ICEs and vehicles

with electric motors that deliver instant

torque over a wide RPM-band, theoretically

no transmission is required to

fulfill standard requirements regarding

drivability and efficiency.

“Of course the development of transmissions

for ICE engines showed soon

that “standard” is not enough. From an

objective point also electric motors have

a peak point of efficiency which can only

be utilized over a wide range of driving

conditions with a multiple speed

transmission. Based on the limited and

expensive battery capacity it seems even

more important to save precious energy

onboard the electric vehicle by optimizing

the drivetrain.

“Recent developments show that a two

to four speed transmission in an electric

vehicle will contribute to achieve higher

efficiency levels, higher top speeds and

even higher performance levels with better

packaging. But apparently there is

also a subjective component of being the

first to offer a multi speed transmission

in electric vehicles similar to the raise

in 8, 9 and 10 speed automatics in fuel

burning vehicles.”

Says Riccardo’s Mack. “With the

nature of the torque-generating capability

(the torque curve) of an electric

motor, a single-speed transmission

should be adequate in a small passenger

car-type application. When applied

to a larger or more luxurious vehicle, a

single reduction ratio will either limit

the lower-end torque or the higher-end

speed capability. To overcome this, a

two-speed transmission will be utilized

to provide more low-end torque at the

wheels while being able to operate at a

higher top speed. A two-speed transmission

will also allow the electric motor to

spend more time operating at or near the

motor’s area of optimum efficiency. We

would predict that we will still use multiratio

transmissions with many of these

electric vehicles.”

About Author

Jack McGuinn, Senior Editor, has a diverse,

20-year history in manufacturing, including

management-level positions in quality assurance

and testing; product development; marketing and

promotion; and industrial journalism. He has been

with Gear Technology since 2005. [10 years in the

gear industry]