Therefore, using advanced CAE tools

focusing on gear and bearing analysis, an

engineer with drivetrain design responsibilities

is able to predict certain performance

behaviors well ahead of any

design-freeze dates, and preferably well

before the tooling is ordered. In fact, the

CAE tools are now advanced to the point

where it’s possible to simulate a virtual

dynamometer, which is able to evaluate

the NVH, durability and efficiency

performance within the same software

environment, for not only a nominal

design, but also factoring in manufacturing

variation.

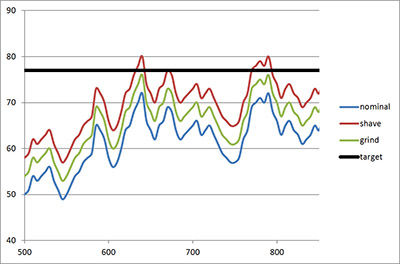

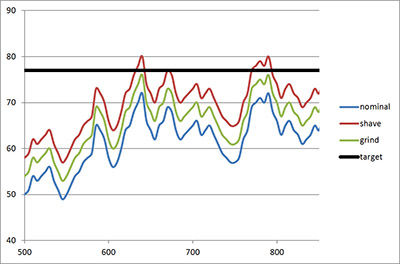

Taken a step further, various manufacturing

processes may also be evaluated

within the context of mass-production.

Figure 3 shows such a gear whine prediction

exercise, factoring in gear microgeometry

variation due to both a shaving

and grinding process, and comparing

the results to a tonal noise target directly

related to passenger compartment subjective

ratings.

Figure 3 Radiated Gear Noise vs. Tonal Target

- Click image to Enlarge

A quick review of the plot shows why

gear whine issues may emerge during

the critical launch phase. Note the nominal

designs all reside below the defined

tonal noise target. This is a normal

expectation, since prototype gears are

often watchfully ground or shaved with

non-production tooling, with the intention

of producing gears as close to the

print design as possible.

But, if the effects of the manufacturing

variation are factored in for the shaving

process, it’s clear that even with all

dimensions well under control, a certain

percentage of the production population

will exceed the allowable tonal noise

limits. Alternatively, the predicted noise

performance of the population using the

grinding tolerances will be under the

target.

The purpose isn’t to show that grinding

is required; the purpose is to show

a methodology factoring in relevant population performance when making

critical design and manufacturing process

decisions, as early as possible. If the

program direction from the example is

to use shaving, a re-design to improve

transmission error is easier to implement

before the design freeze and toolordering

dates. This variation information

is practically impossible to acquire

using test or, within a certain range of

uncertainly, using “experience” only. The

advanced CAE tools improve the OEM’s

ability to make smarter choices for prototype

builds and subsequent testing by

pinpointing critical features and identifying

worst-case production assemblies,

in addition to predicting nominal performance,

so the testing can better represent

the full range of production possibilities.

Troubleshooting 101

Invariably, despite the best efforts of

both the experience-based approach and

the up-front-CAE approach, transmission

and axle gear whine issues will often

emerge. Complicating the engineering

challenge is the trend towards development

of traditional multispeed automatic

transmissions, with complexity well

beyond previous hardware generations,

and of single- and two-speed transmissions

for electric vehicles, with pitchline

velocities approaching or surpassing

those usually associated with superchargers

and other high-speed gearing

applications. Understanding how the

advanced CAE tools can best be used

for addressing a current production

gear whine issue will help both product

and manufacturing engineering teams

resolve the issue at hand by using a physics-

based approach for developing effective

countermeasures.

But first, when presented with an

automotive transmission gear whine

problem, for instance, the intelligent

investigator will ask a series of questions,

intended to help focus on the area

of greatest concern for development of

robust, representative CAE drivetrain

models. The questions for an automotive

application are provided here for consideration,

and can easily be adapted for

any gearbox in any industry.

Automotive Transmission/

Transaxle Gear Whine

Standard Troubleshooting Questions

- What is the nature of the NVH problem?

Is it tonal noise?

- If yes, does it track with engine speed

or wheel speed?

- FWD, RWD-based?

- If you completely disconnect the shift

cable from the transmission/transaxle,

does the noise diminish? Show data.

Be careful not to run anyone over!

- Is the tonal noise present in all gears

or just some gears?

- Drive, coast or cruise/float conditions?

- Is it sensitive to throttle position (gear

train load)?

- Is this a current production vehicle,

pre-production/prototype?

- URGENCY

- How urgent?

- Holding up launch?

- Warranty costs?

- All vehicles or some vehicles?

- If this is a current production vehicle,

was the gear whine quiet at launch,

then it came on recently? Or, was it

always present?

- For the current gear whine issue, are

the gears made to print? Show data.

13. Can you identify a “best of the best”

(BOB) and “worst of the worst”

(WOW) vehicle?

- Swap transmissions. Does the

whine follow the transmission or

the vehicle?

- If it follows the transmission, tear

down the noisy transmission and

re-build it. Is the noise still present

at the same levels? If so, swap out

the suspect gears. Is the noise still

present?

- Tell me about the transmission/transaxle

configuration

- Manual

- Automatic

- Dual-clutch transmission

- Are you sure the noise is not:

Power-take off

- Are you sure the noise is not:

Transfer case

- Are you sure the noise is not: Axle

- Are you sure the noise is not:

engine accessory related

- Does the noise get worse/better/same

with temperature?

Is the same transmission/transaxle

used in another application? Such as

a different model, etc. Is the WOW or

noisy transmission also noisy in this

other application?

- For FWD, if the noise emerged

recently and not always, something

changed. Was it the half-shafts?

Wheel hubs? Mounts? Sound package?

Shift cable? Change suppliers/

materials on any of the above? Are

you sure? Sometimes a part may be

assigned the same number, and look

the same, but tolerancing/materials

could be different.

- Any End-of-line control in transmission/

transaxle plant? Gear quality

SPC charts? Gear inspections?

- What is the gear manufacturing process?

Did anything change?

- IMPORTANT: what is the noise path

from the gear mesh to the passenger

compartment? Are you sure? Show

data.

- NPA techniques: inverse matrix,

dynamic stiffness

- Poor man’s NPA: various disconnects/

wraps

- Are sidebands present? Spacing?

- Does the noise occur at a single

speed/frequency (“peaky”), or is it

present across all speeds/frequencies,

or both?

- If you perform a neutral engine runup,

is the noise present?

The responses to the questions above

will dictate the type of CAE model the

investigator needs to create, and, actually

establish if the tonal noise is even

related to the transmission in question.

Often, tonal noise from other sources

is confused with transmission noise. If

the NVH issue is indeed gear whine,

and is present in all transmissions, and

not just a few, then the fundamental

issue could very well be related to the

basic gear design. If limited to only a

few transmissions, then the issue could

be a special cause in manufacturing,

such as an emerging tooling or assembly

issue, excessive heat treatment distortion,

material quality issues, etc. The

CAE approach would be quite different

either way.

Likewise, the issue could be related

to a changing vehicle path, such as a

transmission mount re-design for durability

issues, resulting in less isolation

for housing vibration; many gear manufacturing

engineers have spent many

long hours “fixing” gears due to vehicle

issues and the application of “ear to gear”

engineering as previously explained. The

questions above help the troubleshooting

team focus on the physics of the problem,

not the politics.

A few basic guidelines for creating a

robust and representative CAE model of

the transmission for gear whine analysis:

-

Model what is tested; never test what

is modelled: A drivetrain CAE tool

capable of analyzing the entire transmission

system, including gears, bearings,

and housings should be used,

especially for planetary-based or

multi-mesh drivetrains (Ref. 5). This

includes full tooth topologies from

multiple teeth from each gear, in order

to perform an accurate non-linear gear

contact analysis. All flexible elements

should be properly modelled with

dynamics-quality meshes, including

the housing, carriers, ring gears, and

shafts for planetary-based transmissions.

Carrier pinion spacing errors,

gear pitch errors, component eccentricities

and concentricities related to

assembly variation, and accurate bearing

geometries are all critical pieces of

information required to build a representative

drivetrain dynamics model

with proper gear and bearing contact

mechanics.

-

Boundary Conditions: The drivetrain

CAE model should include representations

of the boundary conditions

that match the actual hardware

(Refs. 6, 7). If test-based evaluations

are to be performed in-vehicle, on a

dynamometer, or in some cases, using

the end-of-line test system, then the

CAE model needs to perfectly reflect

the upstream and downstream hardware

in order to properly capture the

drivetrain dynamics. The extent of

the required boundary conditions will

vary, depending on the system under

investigation. See Figure 4 for an

example.

Figure 4 Mode Shape Analysis in RomaxDESIGNER

- Click image to Enlarge

-

Customer-Derived Metric: The CAE

predictions should tie in directly with

customer-derived metrics based on

an NPA study, such as radiated noise,

mount vibration, or output shaft torsional

vibration, used in conjunction

with derived tonal noise targets based

on passenger compartment response.

Knowing the magnitude of the

required reduction in noise or vibration

is important to the development

of effective countermeasures.

- Click image to Enlarge

If used effectively in a transmission

product development process, the same

up-front CAE tool used for establishing

the fundamental design can also be used

for troubleshooting unexpected hardware

issues. This assumes the investigator

knows the correct questions to ask,

and like Tesla suggested, is able to properly

interpret the responses in terms of

energy, frequency and vibration.

References

- Zwicker, E. and H. Fastl, Psychoacoustics: Facts

and Models, Springer-Verlag, 1990

- Blommer, M. and M. Clapper, “Masking

Perception Analysis Software (MPAS) for Tonal

Noise Setting in Powertrain NVH,” SAE 2003-

01-1500.

- Williams, J. S., G.C. Steyer and J. Ditman,

“Transmission Tonal Noise: Experimental

Analysis of the NVH Characteristics Which

Influence Vehicle Sound Quality,” Proceedings

of the IMAC XIV, Feb. 1996.

- Abe, T., Y. Cheng, K. Nowaczyk and B.K.

Wilson, “Practical Methods for Managing the

Gear Whine Phenomena,” Proceedings of ASME

2007 10th International Power Transmission and

Gearing Conference, Las Vegas, Nevada, USA.

- Abe, T., Y. Cheng, M. Felice, J. Pears, M.

Platten, A. Smith and B.K. Wilson, “Predicting

Variation in the NVH Characteristics of an

Automatic Transmission using a Detailed

Parametric Modeling Approach,” SAE 2007-

01-2234.

- “Boundary Conditions Affecting Gear Whine

of a Gearbox Housing Acting as a Structural

Member,” SAE Paper 2009-01-2064.

- Wilson, B., G. Peterson, A. Kulkarni and A.

Kanase, “CAE Techniques for System Analysis

of Hypoid Gearset Vibration,” SAE Technical

Paper 2011-01-1502.

About Author

Brian Wilson is Chief

Technical Officer of the

Americas, as well as the

Global NVH Technical

Specialist for Romax

Technology. He has 25 years

of experience in test and CAE

for rotating machinery, with a

specialty in gear whine and rattle.