Profile: Gleason Plastic Gears (GPG)

In this interview, we learn about Gleason Plastic Gears (GPG), a division of Gleason Corporation that specializes in designing and manufacturing plastic gears using their proprietary no-weldline technology. GPG has diversified its customer base and serves various industries such as automotive, medical, electronics, home and leisure, marine, education, and hobby. The interview covers topics such as the advantages of the no-weldline technology, surprising applications where plastic gears are replacing metal gears, promising materials and methods for the future of plastic gears, challenges faced by plastic gear designers, and recent developments in services, software, and manufacturing technology. The interview concludes with an overview of GPG’s plans for the future, including the potential utilization of a Gleason P60 Gear Hobbing Machine for precision hobbing of polymer gears and their focus on biomaterials for environmental reasons.

Gleason Plastic Gears as such was established in 2015. What markets have been the focus of the division and how have the division and its markets evolved?

GPG continues to diversify its customer base and expand into different markets. Automotive and medical have always been key customers, but GPG also provides services to industries such as electronics, home and leisure, marine, education, hobby, etc. It’s not just the molding work either—there are plenty of customers looking for gear and system engineering as well as gear inspection services. Being part of Gleason Corporation, and having KISSsoft AG in Switzerland as well as Gleason Metrology Systems as sister companies, makes GPG excel in design and engineering as well as gear inspection services and differentiates us well in the plastic gear’s market.

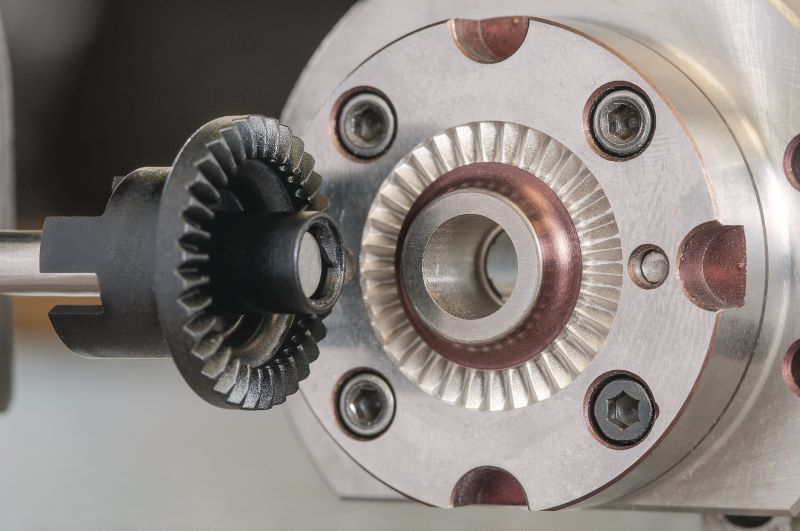

Is the proprietary no-weldline technology still at the heart of GPG? What distinguishes this from other processes?

The no-weldline technology benefits customers in many ways. From a quality standpoint, it allows the gears to be very round and measured at a very high gear quality because the shrinkage is isotropic and close to the material data sheet. From a performance standpoint, we do not have to worry about the integrity of the material strength being compromised at the weldlines, nor residual stresses molded into the gears. From an overall process standpoint, we very rarely have to correct the gear geometry in the tools to account for weldlines. This translates to fewer tooling groom iterations; reduced costs for customers; and fewer headaches from non-round gears that require compensation in the tooling. Overall, we are usually able to hit the tolerances and dimensions for the gears the first time. It is not uncommon to achieve between an ISO A6 to A10 or AGMA Q7 to Q11, depending on the customer’s needs.