Solvay Specialty Polymers for High-Performance Plastic Gears

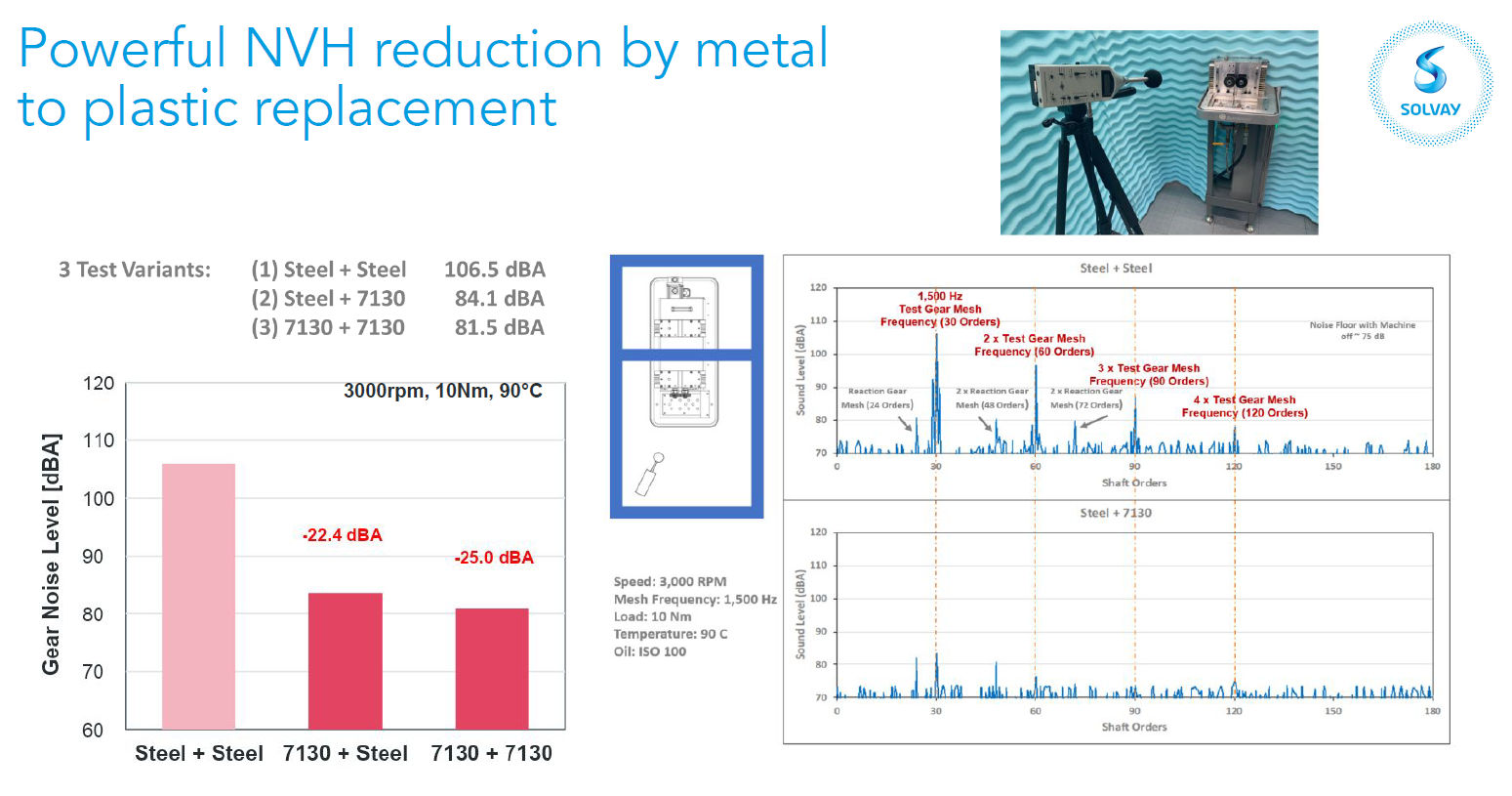

Thermoplastic injection-molded parts in automotive applications is growing and proving significant reductions in NVH issues

Solvay recently helped Allegheny Performance Plastics and Getriebe Technik GmbH (GETEC) explore the possibility of using their Torlon PAI plastic to replace a traditionally metal helical pump gear, which powers an oil pump that lubricates and cools the transmission. When the car is idling and during low engine speed, with RPMs from 800–2000, this gear is known to be the single largest contributor to system noise. The use of high-temperature, high-performance thermoplastic injection-molded parts in automotive applications is growing and proving significant reductions in NVH issues.

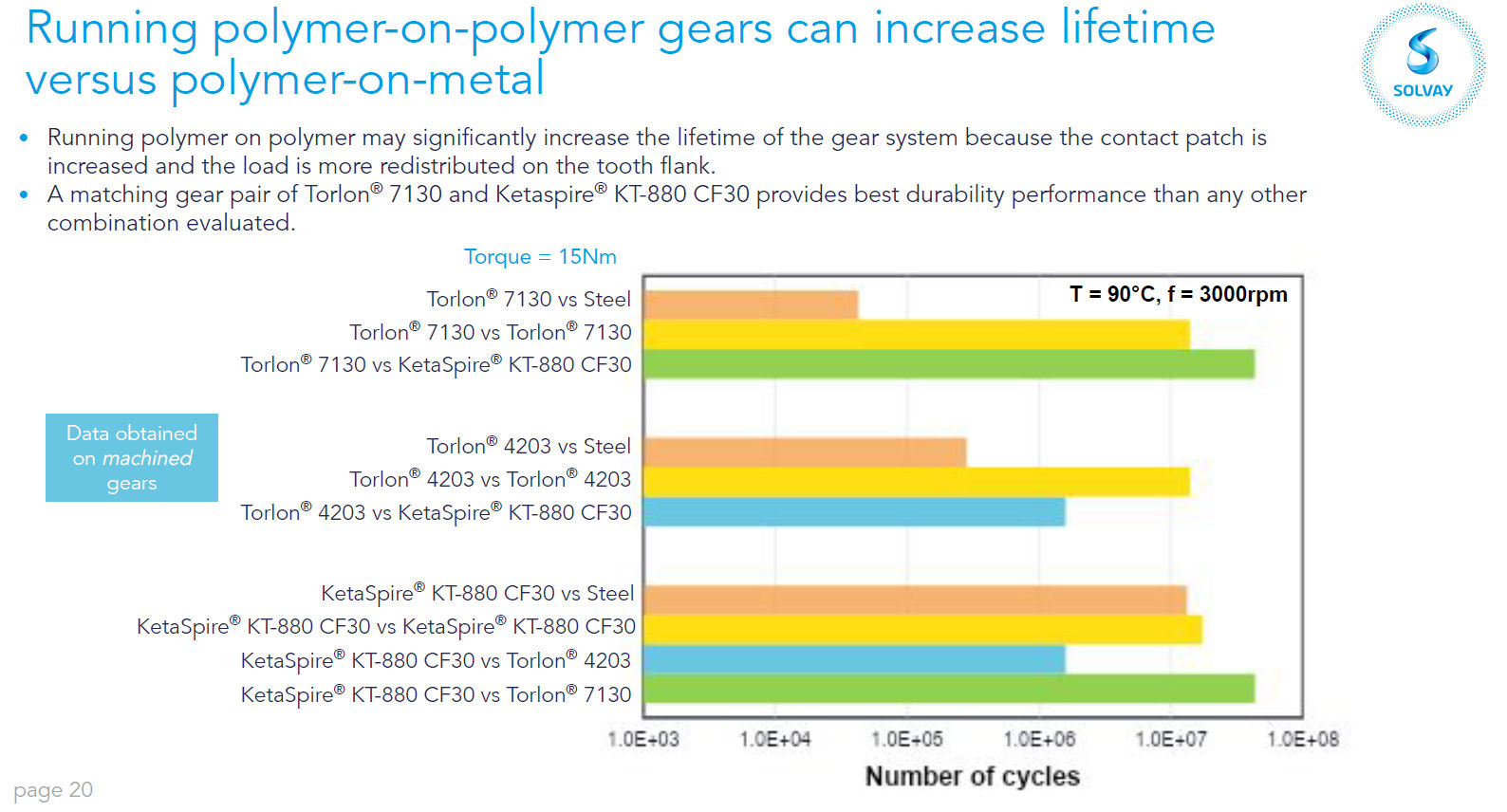

Finite element analysis is a challenging task when dealing with gear applications, and this is especially true since different software is providing different sets of answers. Solvay continues to perform tests on actual plastic-gear prototypes using different material combinations for both machined and molded plastics. The bending and contact stress data for different materials are being updated to simulate gears in KISSSoft and Abaqus. Most notably, relevant data is available for Torlon 4203, Torlon 7130, and KetaSpire KT-880 CF30.

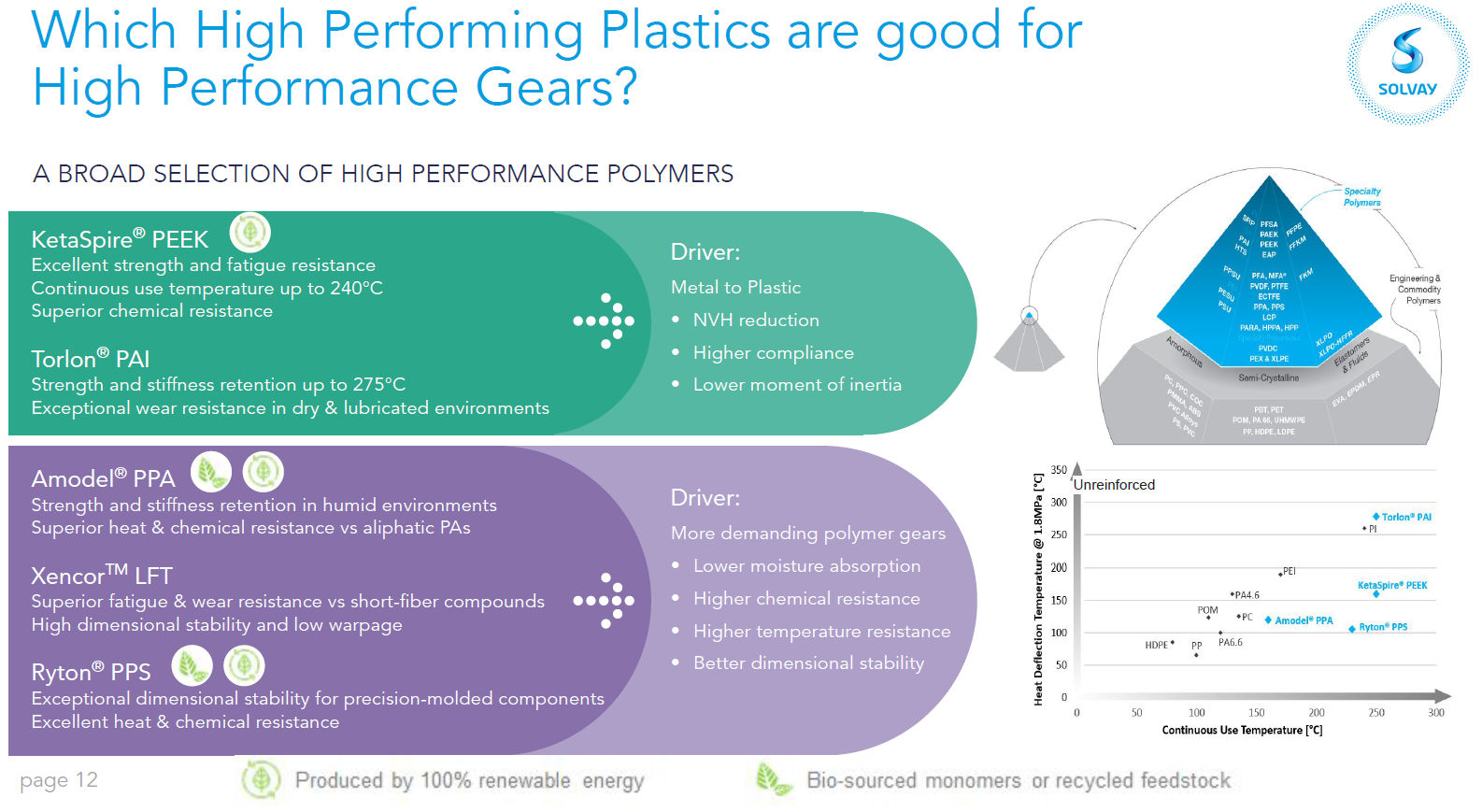

KetaSpire PEEK and Torlon PAI are excellent candidates for gear use not just for their continuous-use temperature properties but for their friction and wear performance in challenging gear mesh conditions. KetaSpire is semicrystalline and Torlon is amorphous. These metal alternatives offer a significant reduction of weight, NVH, and moment of inertia.

In testing, they show excellent performance but in different loading regimes. KetaSpire has improved life over conventional materials at higher load cases, whereas Torlon offers potential for extremely high cycle counts and continuous use, but at moderate loads.