In order to address this, it is imperative

that action is taken during the earliest

parts of the design and analysis

phase, widely identified as the key area

in which process improvements can be

made. Traditionally, the earliest stages

of production are carried out in isolation

with prototypes tested and problems

fixed later during the production process.

The fallout from this includes slow

development cycles, high development

costs, opportunity for miscommunication

and errors, and limited opportunity

for innovation.

Romax’s Right First Time approach

aims to update designs early on in the

design process, where changes can be made with comparative ease, and in turn

minimize late changes in the design and

production process. In order to achieve

this, the developers at Romax have identified

six critical development stages:

- Educate & Evangelize: Senior management

up to the highest levels need to

understand the benefits provided by

early analysis and its strategic importance

in design and development

- Assess: Firms must complete a full

audit of their design and development

process – to understand the scale of

the challenge and better target activity

- Identify: It’s important to find the

“quick win” areas where analysis can

add immediate value

- Implement: Organizations must

deploy appropriate analysis tools in

the area(s) identified – and do so with

commitment based on senior management

buy-in and sponsorship

- Focus: Firms must ensure they have

effective analysis tools at the concept

design stage that are able to consider

layout, center distance, gear and bearing

sizing, loads, packaging, NVH, etc.

- Improve: Firms must be prepared to

continuously monitor, update and

develop their processes – continuous

improvement will consolidate and

extend the gains being made

Providing more focused analysis during

the earliest planning stages enables

comparisons to be made with previous

designs and with competitive products

more easily. For the manufacturers, this

will help determine more realistic target

setting as well as allowing them to

ensure that any changes can be made

quickly and efficiently with minimal

long-term impact.

Addressing Demands for

Improved Performance

Modern-day consumers are conditioned

to constantly expect more power, better

performance, more features, a smaller

carbon footprint, and all for the same

cost or less. The result is increased pressure

to ensure that any potential design

targets and product criteria do not clash

Across an automotive transmission,

engineers have to balance conflicting

requirements of efficiency and noise,

while reducing weight without compromising

durability. All such requirements

are interdependent, and therefore

it’s imperative that before any actions

are taken, you are able to consider the

impact on other components within the

design chain.

One of the clearest examples of this

can be demonstrated when looking at

the hybrid and electric vehicle (HEV)

markets. As the demand for hybrid and

electric vehicles continues to grow, one

of the main challenges that manufacturers

struggle with is improving noise,

vibration, and harshness (NVH).

While the automotive sector has made

steps toward improving NVH — thanks

to improvements across design, analysis,

development and manufacturing

processes — challenges still exist for the

hybrid and electric vehicles sector. EV

and HEV design is altogether a more

complex process than designing traditional

drivetrains; EVs do not benefit

from the “masking” effect of the noise

from internal combustion engines, while

HEVs represent a particular challenge

because vibrations from both the engine

and the motor must be considered, along

with the interactions between them.

In order to address this, simulation

needs to be at the forefront when trying

to reduce NVH. Many manufacturers

work with finite element analysis and

multibody dynamics tools that try to

predict vibration response of the drivetrain

system. However, these processes

can prove to be so time-consuming that

they’re often only used too late in the

design process for the problems to be

resolved.

If manufacturers have access to software

that can simulate different solutions

in the earliest design phase before

they are produced, organizations can

save vast amounts of cost and time. To

support this it is important to ensure

companies have the right CAE tools and

development processes in place.

Putting this into Practice – GKN

Case Study

GKN Driveline has applied Romax

Technology software and consulting to

focus the optimization of gearbox efficiency

in electric motor-driven transmissions

without compromising noise

and durability.

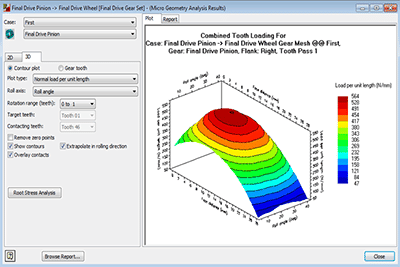

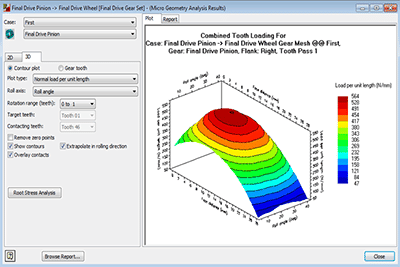

After identifying the main contributors

to power loss, investigating how

changes to macro- and micro-geometry

would affect efficiency, and optimizing

the geared system in RomaxDesigner,

GKN Driveline manufactured the resulting

gears and evaluated experimentally

the driveline efficiency. Results showed

improvements across the speed and

torque range of interest of up to 2 percent

without compromising on durability

and NVH. This provided valuable

insights into how GKN Driveline continuously

initiates performance improvements

in its customer applications.

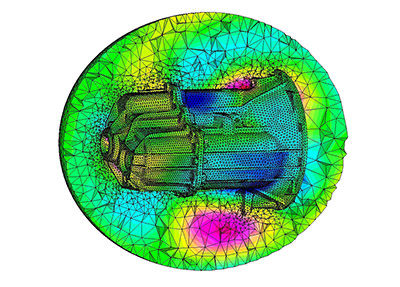

Figure 3 Tooth contact in RomaxDesigner.

- Click image to enlarge

Hybrids and EVs: a Market

Opportunity

GKN Driveline develops the latest driveshaft

and geared component technologies.

“During first hype of electrification four to five years ago, everyone talked

about quick introduction of batteryelectric

vehicles,” says Theo Gassmann,

vice president of Advanced Engineering.

“The reality was that the technology

wasn’t ready — for instance, battery technology

is too expensive — and customers

aren’t ready, particularly regarding range

limitations. So the EV market experienced

a slow start.” He says this led companies

to change strategy, embracing a

hybrid approach to develop the marketplace.

“GKN Driveline, as market leader in

driveline technology, is growing fast in

conventional and electrified driveline

systems. Coming from AWD systems,

we successfully launched transmissions

for hybrid and electric vehicles in the

last years. Transmission has not been

our core business but we utilized our

driveline expertise and technologies to

expand our portfolio successfully.”

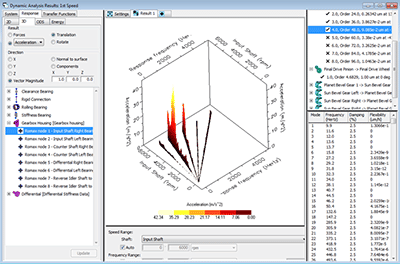

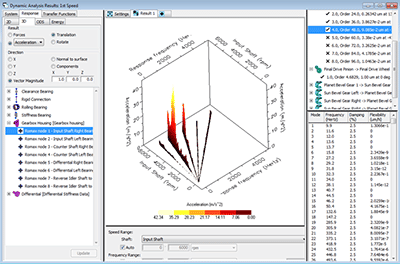

Figure 4 Vibration response calculation in RomaxDesigner

- Click image to enlarge

Gassmann says transmission issues for

EV and HEV are broadly similar to nonelectric

applications: “Powertrain efficiency,

durability and NVH. Differences

come regarding the duty cycle and loads,

between coast and drive. The driveline is

different. And when you have to invest

in battery capacity, you don’t want to

waste energy in the transmission. The

biggest challenge is arguably NVH.

Missing masking noise from combustion

engine and lightweight-design leads to

an early focus on NVH improvements.”

The Value of the Right Analysis

System

Conventional methods to increase transmission

efficiency can have adverse

effects on durability and quiet running;

lack of engine noise in EVs renders current

design practices unacceptable. In

addition, the pressure to improve efficiency

of the eDrive gearbox in GKN

Driveline’s all-wheel drive hybrids

required a new approach. “We’ve worked

with Romax for several years, in a stepby-

step process that started in Japan

then moved into Germany and Sweden,”

says Dr. Artur Grunwald, supervisor of

Advanced Geared Systems Calculations.

“We saw the value of analyzing the

whole system, to identify where the

greatest benefits could be gained, then

working to balance efficiency, durability

and NVH across the entire system.

RomaxDesigner provided the accuracy in

modeling and analysis, and we worked

with Romax people on a project and

consulting basis to learn how to best use

the software and apply our engineering

expertise.

“We use RomaxDesigner for problem

solving and for system optimization

from concept to production design.

Perfect components don’t always equal

a perfect system when combined. That’s

why we use RomaxDesigner: it shows

where you can have the most impact and

where the benefits lie. It’s one of the few

software systems capable of this type of

system analysis. Our goal is, systematically,

to separate the useful parameters

from the possible in order to enable the

biggest benefit at acceptable cost level.”

Taking a Whole System Approach

to Optimize Design

Romax’s abilities to improve efficiency

were tested in a project that saw an

eDrive gearbox connecting an electric

drive to the rear axle of a PSA Peugeot

Citroen passenger car, with a conventional

internal combustion drive connected

to the front wheels. The original

gearbox was analyzed using

RomaxDesigner, which explored potential

improvements to gear geometries,

comparing predicted NVH and durability

with the original design.

GKN Driveline manufactured a redesigned

set of gears, with extensive tests

confirming overall efficiency improvements

and, in the all-important coast

condition that determines energy recuperation

performance, the 1–2 percent

gain across the speed and torque range

required. “The efficiency of the gearbox

was assessed by calculation of the component

losses from gears, bearings, seals

and oil churning,” Dr. Grunwald says.

“Efficiency results from the simulation

are compared against frictional

torque measurements taken during

testing under a range of torques and

speeds. The methodology used allows

advanced parametric studies to be carried

out in an all-in-one approach with

RomaxDesigner to consider the effect of

a wide range of design changes on efficiency

at the same time as durability and

NVH performance.”

He adds, “We also have several years’

experience of working with Romax people,

who have been extremely reliable

and professional. We clearly benefit from

that valuable experience. As a business,

we want to develop a common understanding

of simulation issues and use

consistent methodologies from concept

to production. Our requirement to take

a whole-system approach will increase

with future projects and applications,

and across different regions and product

ranges. The way RomaxDesigner integrates

with other software packages also

saves us time. Its ability to provide interfaces

and to share results for interpretation

by our engineers is another reason

we use it internationally.”

Gassmann adds, “We’re moving into

a new era of hybrids and electric cars.

Genuinely high-performance products

demand the effective application of system

know-how from concept to production,

so you can find the best possible

balance.”

Meeting the Demands of a New

World

Calls for innovation can be triggered by

a variety of factors. It could be from a

demand to keep up with competition,

a demand to incorporate technology

enhancements, or even a demand to satisfy

compliance and legislative changes.

In line with this, it is important to

understand the impact on not just the

internal design process, but also the need

to account for external variables.

Probably the best example of this can

currently be seen in Europe, notably the

EU’s plans for addressing growing carbon

emissions amongst all passenger

vehicles. Currently, the EU has put in

place a comprehensive legal framework

designed to reduce CO2 emissions from

new light-duty vehicles as part of efforts

to ensure it meets greenhouse gas emission

reduction targets under the Kyoto

Protocol and beyond. Car manufacturers

are obliged to ensure that new fleet cars

do not emit more than an average of 130

grams of CO2 per kilometre (g CO2/Km)

by 2015 and 95g by 2021.

The fallout of this has seen major

OEMs, led by some of the industry’s biggest

car manufacturers, actively developing

low-carbon, electro-mechanical

drivelines and vehicle technologies to

address consumer demands while still

meeting the requirements of the EU.

While it is reassuring to see positive

actions being taken, what often

isn’t considered is the impact of realworld

variables on those early design

phases. Earlier this year, a study carried

out by Romax in collaboration with

Loughborough University in the U.K.

revealed that fuel consumption in the

automotive industry can differ by as

much as 20 percent when comparing

real-world drive cycles to that of rig and

simulated tests based on legislative drive

cycles. This demonstrates the significant

variances which exist when it comes to

fuel efficiency.

The findings, which stemmed from

the impending EU legislations, were part

of a three-year investigation into the factors

that influence energy consumption

across hybrid electric vehicles, and how

real-world driving differs from legislative

test cycles. The interesting point of

note is that the findings clearly demonstrate

that while traditional design tools

used by manufacturers tend to focus on

efficiency against a single drive cycle,

they don’t account for the robustness of

a vehicle’s performance against a set of

drive cycles or against external factors

such as locational influence.

Tests are carried out in a very regimented

environment and rarely account

for outside influences

and as a result, the

data achieved from this

is rarely put to effective

use. In light of this, it

is imperative that organizations

start to make

the most of data streams

available to them, and

doing so at the earliest

points of the concept

design stages. Embracing

this would dramatically

smooth the transition

from one drive cycle to

another, with significant

cost reductions being

seen through greater fuel

efficiencies.

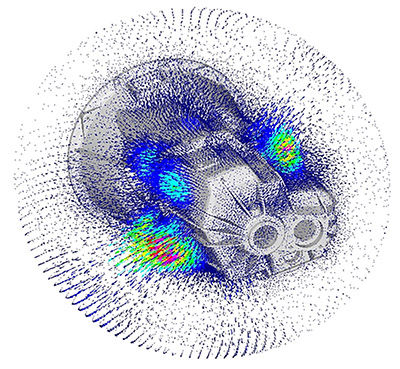

Figure 5 Mode shape analysis in RomaxDesigner.

- Click image to enlarge

As a final thought, it is

important to recognize

that OEMs have and will continue to use

a wide array of individual software tools

and methods to simulate and design

driveline components. The problem that

arises is that no matter how good these

standalone tools or individual analysis

processes are, they often fail to account

for unforeseen problems or external

variables, when combining components

into the complete system.

As demand for faster, smarter and

more cost-effective design increases, so

does the need to provide innovative simulation

tools, which can encapsulate the

entire driveline system, allowing for it to

be modeled and simulated quickly, accurately,

repeatedly and as early in the process

as you want.

As a company, this is what we at

Romax are committed to providing our

customers. Our solutions are designed

with the intentions of being integrated

into the overall design and development

process, with end-to-end tools designed

to address all elements from product

planning to manufacturing.

This quarter, Romax is announcing

its new comprehensive gear design tool,

embedded into its Concept product. This

will enable gear design to be part of a

fully integrated system-level design and

development process which includes

system durability, efficiency and NVH,

rather than being the standalone activity

which it often is today. See Romax at

booth #1402 at Gear Expo 2015, October

20–22 in Detroit.

About Author

Dr. Jamie Pears

Dr. Jamie Pears is

the Head of Product

Management at Romax

Technology. He has a M.Sc.

and Ph.D. in Physics from

Nottingham University,

UK. He joined Romax

Technology in October

2000 as a software developer working on

the RomaxDesigner analysis code and the

RomaxNVH software. Since then he has

been involved in engineering projects as the

NVH Team Leader, performing consultancy

for many worldwide customers. He has also

served as R&D Manager and Software Team

Manager. His current role involves setting the

overall direction of the Romax Technology

software products, communicating with

customers and directing the software

development team.