The Role of Virtual Prototyping in Gear System Design and Manufacturing for E-Mobility

The combination of full-system simulation and gear-machining simulation ensures manufacturability

Apart from what Hollywood’s sound engineers have done to bring the vehicles of science fiction to life in film, there isn’t a common precedent of what an EV should sound like to us. There are many roads that can be taken toward that end, which could involve altering the real sounds of an EV into something as familiar as an ICE (not unlike the principle of ICE vehicles equipped with a sound symposer to make them sound even more like an ICE) or something entirely novel that manufacturers may develop into their signature sound of the electrification era.

NVH is a key metric in drive-system development for e-mobility. Careful design and manufacturing of gears are crucial to minimizing NVH, as tolerance variations can result in large differences between nominally identical components. Failure to factor for NVH will force manufacturers to adopt absorbent masking techniques that will add weight or cost or both—and likely reduce energy efficiency.

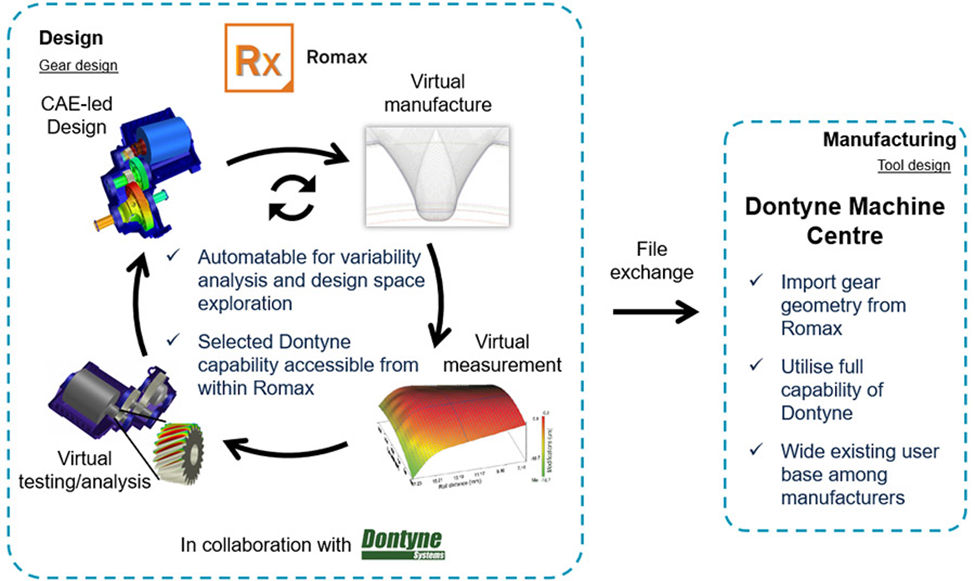

Hexagon is working to address NVH and other drivetrain issues, through a recent collaboration between their Romax toolset and Dontyne Systems, with virtual prototyping (VP) solutions that account for the manufacturing process at the design stage. Dontyne’s manufacturing simulation capabilities are embedded into Romax design products. Romax models interactions between key components (shafts, gears, bearings, housings) and the subsequent impact on shaft deflection, gear contact patterns, misalignment, transmission error, acoustic radiation, etc. Component measurement processes can be augmented through simulation to gain insight into system performance before sub-system and system testing. It is obviously far less expensive and far quicker to resolve design issues during the design rather than production stages, but engineers are rarely equipped with comprehensive tools and expertise to consider every aspect of manufacturing variability at the outset.

The combination of Romax’s full-system simulation and Dontyne’s gear-machining simulation ensures manufacturability. Romax can then export gear sets to Dontyne’s Machine Center for detailed tooling design and other manufacturing procedures. Kristian Kouumdjieff, product manager for Romax, said, “In their efforts to make the transition to e-mobility in a time- and cost-effective way, global manufacturers, OEMs and Tier 1s are investing heavily in new technologies and learning how to overcome new product development challenges.”

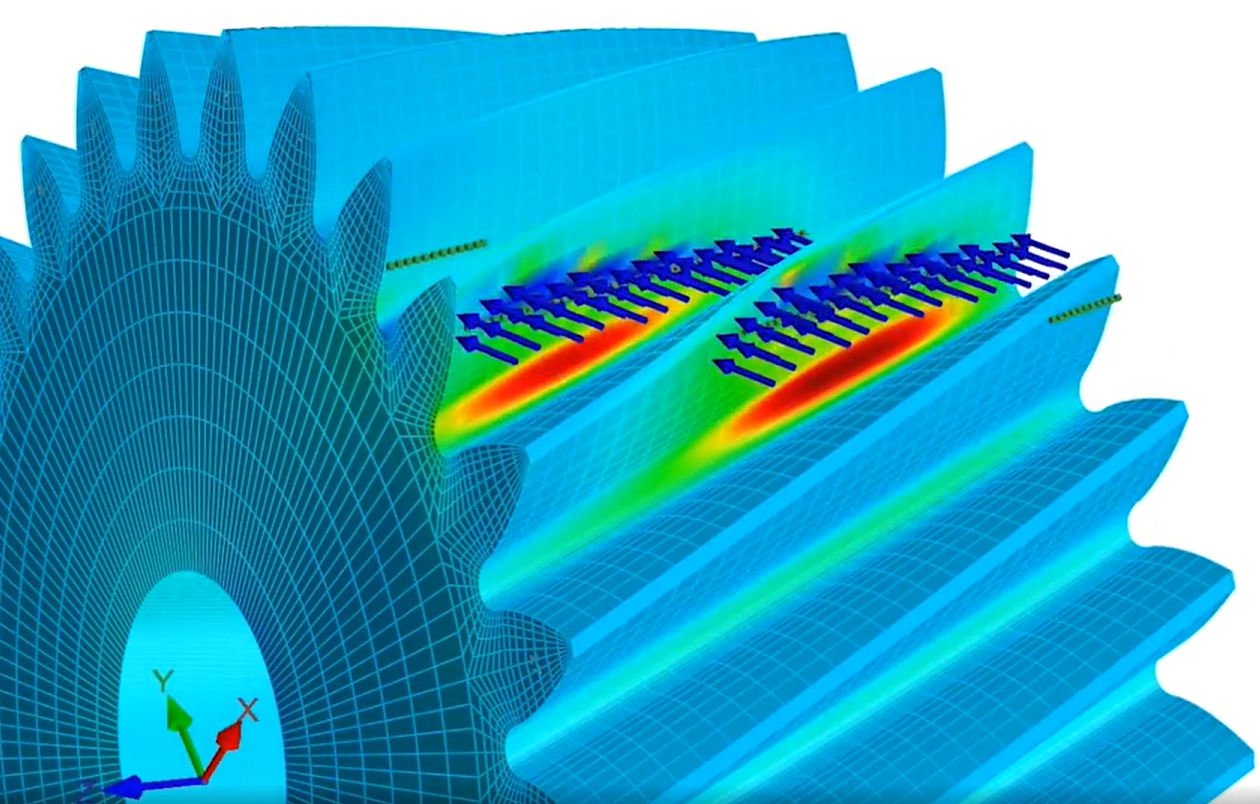

Courtesy of Hexagon

Courtesy of HexagonSince tooling parameters are automatically estimated based on the designed geometry, it is not necessary to have a deep understanding of gear manufacturing to use the software. However, it is possible to view all the details of the tooling and the gear finishing simulation performed by Dontyne and to have more manual control over the settings.

Gear measurements provide very useful data about the achieved gear profiles, which can be fed directly into full-system simulation models like the ones used for design and analysis earlier in the process. The designed gear geometry undergoes tooth contact analysis is considered in the context of the overall drive system for durability, NVH, and micro-geometry-based efficiency analysis.