A New Level of Added Value

Market changes and mutual dependencies between value creation stages require both new technical and economical solutions. How can companies face these challenges with greater resilience? How can we exploit the benefits of increased cost-effectiveness? These questions are being posed by the transnational "EuProGigant" project. The aim is to ensure smart, sovereign use of data for production and bring this to Europe.

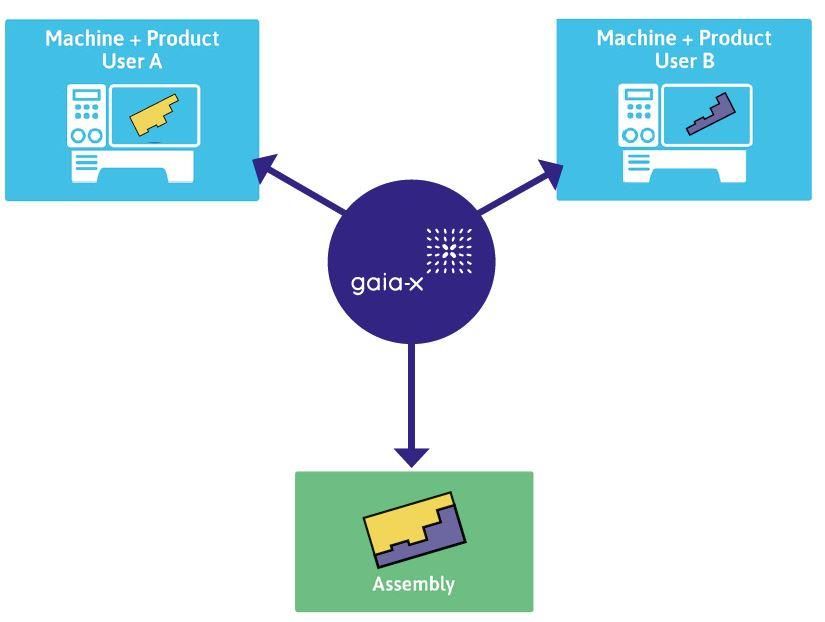

Perfect component matching: This working group is planning an automated comparison of individual parts, taking account of tolerance deviations. Information from different data sources is brought together here, enabling optimized grouping of assemblies. This creates added value which is reflected in the reduced amount of time for manual installation, as well as fewer rejects.

Perfect component matching: This working group is planning an automated comparison of individual parts, taking account of tolerance deviations. Information from different data sources is brought together here, enabling optimized grouping of assemblies. This creates added value which is reflected in the reduced amount of time for manual installation, as well as fewer rejects. In the “EuProGigant” project, production-related data is identified, extracted, and organized. Through Gaia-X (a sovereign data infrastructure for Europe), a data sovereignty rule is established, communication structures are considered part of a European data cloud environment, and these concepts are carried over into the area of production. An initial demonstrator was presented at the Hannover Messe in May 2022, featuring data trading, data sovereignty aspects, and data protection-related issues. This is mapped in the structure, information data, and technical mechanisms. The next step is about projecting this technology onto actual use cases and bringing it into production. WFL is one of the key implementation partners in the project.

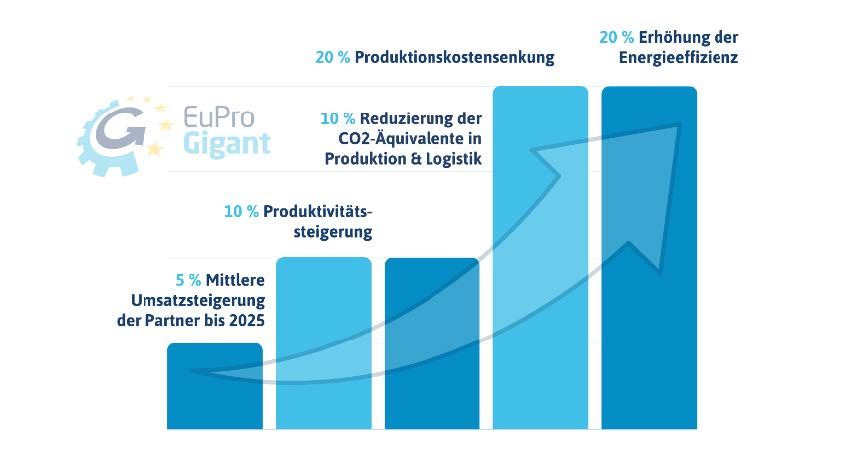

EuProGigant aims to achieve the following, quantified effect.

EuProGigant aims to achieve the following, quantified effect.In order to obtain meaningful data, users of WFL machines are part of the consortium. Plasser & Theurer, for example, bought a WFL machine with automation in 2022. The machine is supposed to run without human interference and use process monitoring to move data from the machine to a control level. The assessments will be made in-house, but thanks to the communication standard Gaia-C, this is set to take place beyond the company’s borders to enable integration in a production network and the exchange of information—on tolerance values, for example. Other machine manufacturers in the consortium include Heller and Arburg. At Heller, a WFL machine is in spindle production, where it performs the essential turning machining process. Arburg has other machines which perform the essential turning/milling processes for hydraulic functions when introducing the subsequent injection molding tools. At the IFT (Institute for production technology) in Vienna, there is an M35, which is used to perform tests and evaluations. The aim is to transfer the results to its partners’ production sites.

Perfect component matching

The M35 MILLTURN, which is at the IFT at Vienna University of Technology, is integrated into a data communications network as part of a collaboration line. There is also an application/working group called ‘Perfect component matching’. It poses the following questions: How can we ensure that the function of an assembly is guaranteed following the assembly process? How can we influence production steps and assembly processes here? And how can we skillfully bring together finished components with the right join partners so that they meet the functional requirements straightaway? After all, this saves having to perform a goods inward inspection. It saves on infrastructure, as testing infrastructure is used by both suppliers and customers. Ultimately, it speeds up the assembly process. You no longer need to search for the right component or perform rework, as this is considered from the outset in terms of functional fulfillment and fed back to the production steps.

In the laboratory of the Institute of Production Engineering at the TU Vienna, an M35 MILLTURN is used for research in the field of Industry 4.0.

In the laboratory of the Institute of Production Engineering at the TU Vienna, an M35 MILLTURN is used for research in the field of Industry 4.0.What can we specifically do now to ensure that the right counterpart is found for an existing component? This is a real issue that is currently being performed with manual intermediate or storage work steps. This brings to mind, for example, the recurring grinding of spacer rings, which need to be machined with high precision in the tenths to hundredths of μ range. Approaches to this are provided by means of intelligent support in the form of a component matching service. This helps with the batch that is delivered by customer A: do such and such components match the components from supplier B with the exact type number? We already have this information before the parts even reach installation. Accelerated support through digital processes and thereby faster value creation are the clear outputs here. However, behind it all, there must be a data infrastructure that facilitates this type of service.