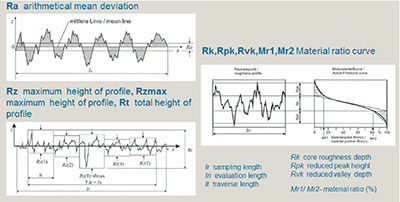

The most important roughness parameters

for flank measurements are shown

in Figure 5.

Figure 5 Roughness parameters according to DIN EN ISO 4287/13565.- Click image to Enlarge

The arithmetic mean roughness value

Ra is the ordinate value of the roughness

profile within a single measurement path

lr. The individual roughness depth Rz is

the sum of the distance between the profile

peak and profile valley within a single

measurement path lr. Like Ra, the averaged

roughness profile Rz is determined

as an arithmetic mean from the individual

measurement paths.

The total height of the roughness profile

Rt is the sum of the height of the largest

profile peak and the depth of the largest

profile valley within the measurement

path ln. The maximum individual roughness

depth Rmax is the largest individual

roughness depths Rz. The stock portion

Rmr is the ratio of the sum of the stockfilled

lengths Ml1-Mli for the total measuring

path ln as a percent value.

The core roughness depth Rk is the

depth of the roughness core profile. The

reduced peak height Rpk is the height

determined from the peaks projecting

beyond the core area. The reduced

peak depth Rvk is the height determined for the striations extending from the

core area into the stock. The parameters

Mr1and Mr2 of the stock percentage

curve characterize the stock content at

the limits of the roughness profile Mr.

Measuring Methods and

Measuring Equipment for

Roughness Measurement

In the VDI/VDE 2602 directive, and

the DIN EN ISO 4287 and DIN EN ISO

16610-21 standard, these are profile

methods that describe the properties of

the profile equipment and the generalcase

measurement conditions for roughness

measurements of surfaces.

Skid-less probing systems and instruments

with lateral skid (at the side off)

are typically used to measure flank

roughness (Ref. 1).

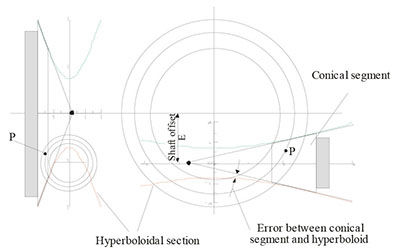

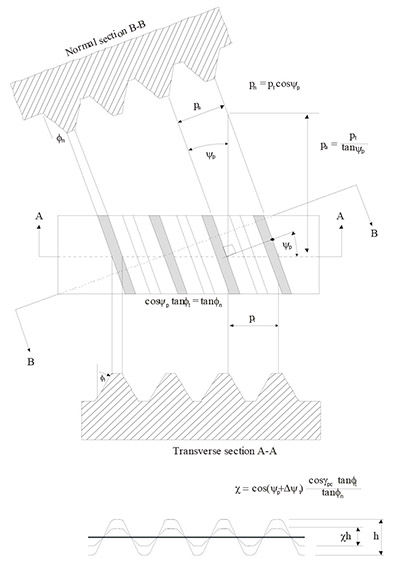

Figure 6 shows the tracing situation of

a skid-less probing system in the tooth

space. The profile here must be aligned

as parallel as possible to the tracing direction

of the test device. In the result, however,

there is always a difference between

the straight trace direction and the

curved flank. The overall profile must

therefore be corrected with a compensation

arc, or residual errors must be eliminated

with the lambda C profile filter.

The possible trace path is limited due to

the curved profile surface and the measuring

range of the roughness probe

Figure 6 Skid less probing system with plane reference.- Click image to Enlarge

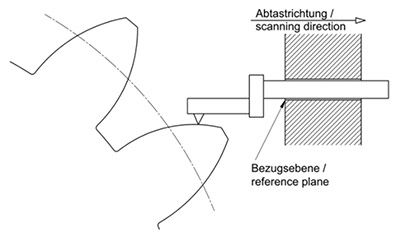

The probing conditions of a skid system

are shown in Figure 7. The sidemounted

probe skid follows the profile

of the tooth flank. A deviation due to

changing contact conditions during the

roughness measurement must be taken

into account here. The deviations are relatively

small, however, and are largely

eliminated due to profile filtering.

Figure 7 Probe system with side mounted skid probe (VDI/VDE 2612 Sheet 5).- Click image to Enlarge

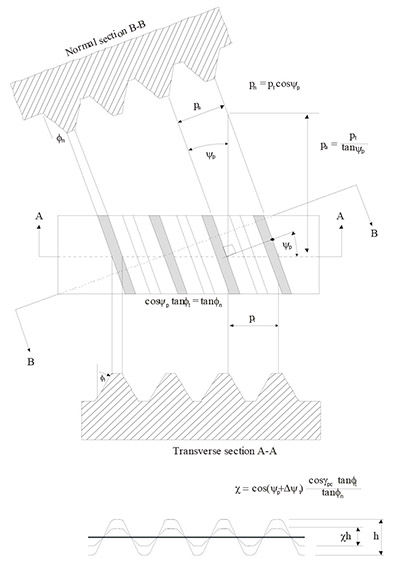

For roughness measurement on cylindrical

gear flanks, measuring devices with

an involute reference (Fig. 8) offer certain

advantages. Logging of measured values

in profile generation mode on the tooth

flank (involute) ensures that the probe

tip is always aligned perpendicular to the

surface; thus the roughness can theoretically

be scanned over the entire profile

length. The disadvantage of this type of

contact operation, however, is that the

scanning speed for measured value logging

is not constant, nor is a uniform

measuring point distance ensured. But this is a minor disadvantage, resulting in

measured value differences of up to 10%.

Figure 8 Skid probe system with involute reference (VDI/VDE 2612 Sheet 5).- Click image to Enlarge

On current gear measuring centers, the

involute reference is generated via CNC

path control and can be used in principle

in conjunction with skid-less systems

and skid systems. For special profiles and

bevel gear flanks with other profile forms,

for instance, the CNC-guided path control

can also execute reference profiles.

Roughness Measurement Procedure in

Practice

The measuring conditions (Ref. 1)

must first be defined in order to achieve

generally comparable results. The following

points must be taken into account to

avoid measurement deviations:

- Probe system

- Profile filter

- Alignment of test specimen

- Environmental influences

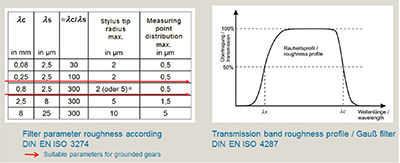

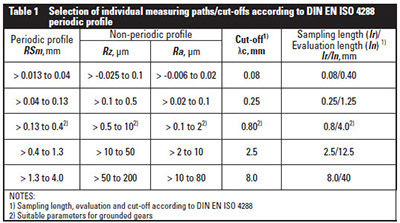

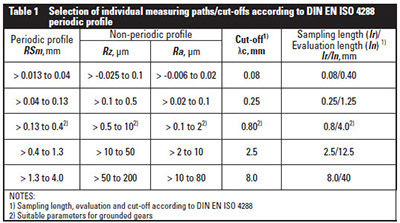

Refer to Table 1 to select appropriate

individual measurement paths and cutoff.

As finish-machined surfaces on tooth

flanks in particular must be tested, the

highlighted values should be used preferentially.

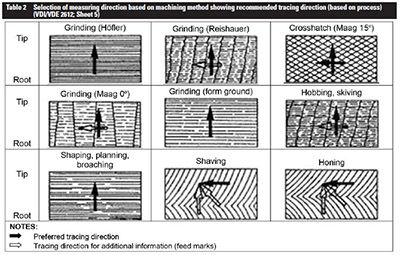

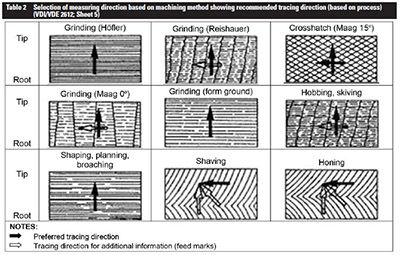

The measuring direction for

the roughness measurement should be

selected according to Table 2, based on

the machining method and the resulting

structures.

- Click image to Enlarge

- Click image to Enlarge

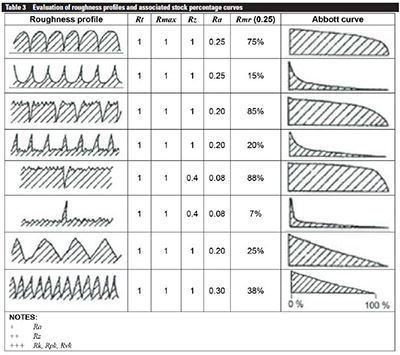

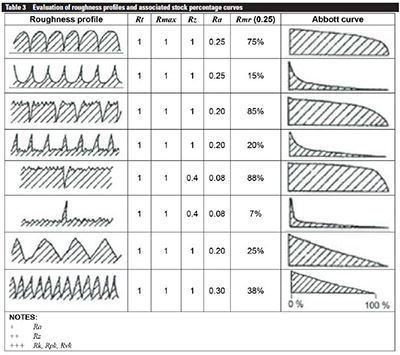

When selecting the appropriate parameters

for the roughness measurement on

tooth flanks, the stress on these surfaces

due to compression and sliding must be

taken into account. The parameter Rmax

has little meaning for this stress, as individually

projecting peaks, which are of

little relevance for the load capacity, are

taken into account here. The arithmetic

mean raw value Ra is greatly distributed,

but correlates the least with the function

parameters and therefore should not be

used. The preferred parameter for roughness

on flank surfaces is Rz, as it provides

a high degree of clarity and makes it possible

to draw accurate conclusions about

the height of the roughness profile.

In addition to the parameters that

describe only the vertical expansion of

the roughness profile, it is important to

determine the roughness structure in

order to determine the wear behavior or

load capacity of a tooth flank. The stock

percentage curve (Abbott-Firestone)

and the resulting parameters Rk, Rpk

and Rvk are appropriate for determining

the structure of the roughness profile. A

nearly S-shaped pattern in the stock percentage

curve is ideal. Another appropriate

parameter for the stock percentage is

Rmr (c). See Table 3 for a comparison of

roughness parameters and stock percentage

curves.

- Click image to Enlarge

A standard roughness testing device

(Ref. 3) is shown in Figure 9. In addition

to a feed mechanism with a microprobe

system, the device also features a

cross-slide to position and test the workpiece.

An additional clamping fixture is

generally needed to test toothed gears.

According to the figure detail, compact

reference area probe systems with an

application range from module 0.5 can

be used here. A PC computing system

with high-performance software is available

to control and evaluate the roughness

measurements. The evaluation software

takes into account a large number of

established roughness measurement standards.

A report printout of the measuring

results can be custom-designed.

Figure 9 Standard roughness test device — example stationary surface measuring station for

gears (Mahr catalog).- Click image to Enlarge

One advantage of the device presented

is that general workpieces can also be

tested, and a higher standard overall is

provided for roughness measurement. It

does, however, require more set-up for

flank measurements and the device is not

suitable for large and heavy workpieces

(500 mm in diameter, for example).

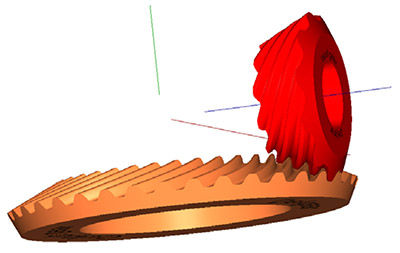

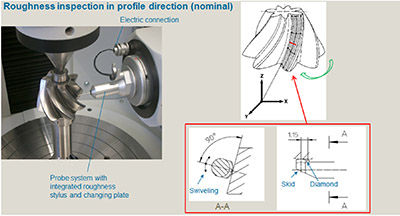

Application example: cylindrical gear/

bevel gear measurement on gear measuring

centers. Gear measuring centers

are typically equipped with a rotary

table for testing rotationally symmetrical

workpieces and are suitable for measured

value logging on small to very large workpieces, in conjunction with a model

series. As previously described, the measuring

method used here is the involute

reference in combination with a skid system.

For roughness measurement a special

probe system on the adapter plate of the

measuring machine’s macro probe system

is adapted (Fig. 10). An additional electrical

connection is provided for transferring

the measured values from the integrated

micro-probe system for the roughness

measurement. For measured value

logging in the profile direction, the probe

skid rests on the flank to be tested and

executes a movement similar to a normal

profile measurement for the macrostructure

of the flank. As it does so, a diamond

needle located in front of the probe skid

logs the measured values for the roughness

measurement. The probe system

represented here is also suitable for measured

value logging in the tooth trace

direction. The roughness probe system

also features an adjustment mechanism

enabling the probe needle to be aligned

perpendicular to the surface for helical

cylindrical gears as well.

Figure 10 Roughness testing device (cylindrical gear) on gear measuring centers — roughness

inspection in profile direction (involute reference).- Click image to Enlarge

Thus in conjunction with an automatic

probe change rack, a fully automatic process

can be carried out for the roughness

measurement in combination with other

gear measurements. Because the measured

value logging is controlled by the

CNC-guided measuring axes, this results

in highly precise positional accuracy and

reproducibility for the measuring positions.

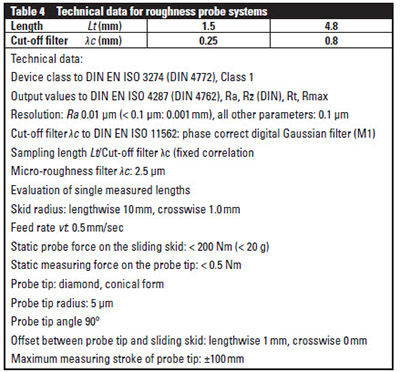

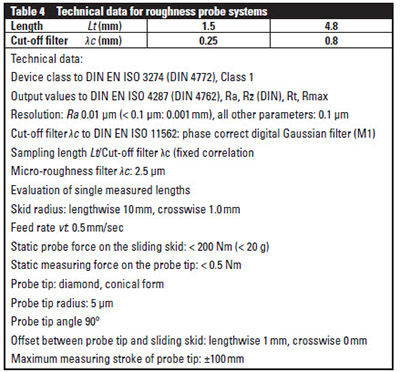

The most important technical data

for the integrated roughness test equipment

are shown in Table 4.

- Click image to Enlarge

To document the measuring results,

the roughness parameters can also be

documented on the standard measuring

sheet for profile and reference tooth

traces, or they can be printed as a separate

measuring sheet including diagrams

(Fig. 11).

Figure 11 Results output: roughness measurement on gear measuring centers.- Click image to Enlarge

Comparable to measured value logging

on cylindrical gears, roughness measurements

can also be conducted on bevel

gears. The profile measurement here

takes place based on the calculated nominal

data, which are available in high resolution

for measuring the macrostructure.

Various probe systems are used for

measured value logging, depending on the design of the bevel gears pinions/

ring gears. For pinion shafts a straight

probe system is used — exactly like

the probe system for cylindrical gears

(Fig. 12) — and an angled system is used

for ring gears.

Figure 12 Roughness testing device (bevel gear) on gear measuring centers.- Click image to Enlarge

A fully automatic test sequence can

also be specified via the software operator

guidance. Measuring positions, measuring

paths, and the number of flanks to

be tested, etc., can be programmed individually

(Fig. 13). The measuring results

are displayed numerically on the screen

for the selected flanks (Fig. 14); measured

values can also be printed out with diagrams

(Fig. 15).

Figure 13 Operator guidance: roughness measurement on gear measuring centers.- Click image to Enlarge

Figure 14 Results output: roughness measurement on gear measuring centers.- Click image to Enlarge

Figure 15 Roughness bevel diagram.- Click image to Enlarge

Thus the device presented here offers

a reliable, convenient measuring method

for roughness measurement on spiral

bevel gears with spatially pronounced

curves. Large-module bevel gears can

also be tested in conjunction with suitable

probe systems.

Concluding Remarks

These important measured values can be

carried out quickly and easily in conjunction

with conducting roughness measurements

of tooth flanks on gear measuring

centers using the equipment presented

here.

Measurements on both smaller and

larger gear teeth can be taken in a single clamping in conjunction with standard

test parameters.

The measurement conditions for

standardized roughness measurements

are largely met by measured value logging

in the profile direction with CNCcontrolled

contouring in generation

mode for each tooth profile.

References

- VDI/VDE 2612; Sheet 5. Measurement

and Testing of Gearings: Surface Roughness

Measurement of Cylindrical Gears and Bevel

Gears by Means of Stylus-Type Instruments

(Release 2014/2015).

- Jenoptik publication.

- Mahr publication. “Mar Surf XR 20 Roughness

Testing Device

About Author

Dipl.-Ing. Günter Mikoleizig currently heads the product

management and application engineering department for gear

inspection machines at Klingelnberg GmbH, Germany. With more

than 30 years in the field of gear inspection technology, he is

fully experienced with the design and development of inspection

machines and their product management. He in fact developed

a product line of inspection machines for an array of gears and

related parts, with small dimensions up to the very large-sized.

Mikoleizig has presented papers about gear inspection worldwide and is also an

active member of national and international standardization committees.