NCSIMUL CAM Streamlines CNC Programming

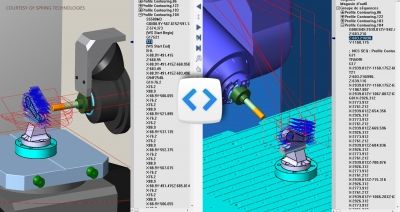

Spring Technologies, vendor of software that optimizes the use of NC Machines, recently announced the worldwide launch of NCSIMUL CAM. This new product delivers CNC programming to streamline the current CAM process and provides increased flexibility on the shop floor.

Fully integrated in the new unified NCSIMUL SOLUTIONS V10 platform (including NCSIMUL MACHINE, NCSIMUL TOOL, and NCSIMUL DNC), it embodies Spring Technologies’ response to today’s issues in CNC machine programming: removing the typical organizational method of tool path generation (CAM), post-processing, G-code verification and simulation and streamlining the conventional CNC programming process.

“This is a major new step forward for the company’s product strategy and in the manufacturing industry,” said Philippe Solignac, corporate marketing director for Spring Technologies.

NCSIMUL CAM directly generates verified and optimized CNC programs, while factoring in the physical resources available on the shop floor, including tools, cutting conditions, kinematics and machine controllers.

With this new solution CAM data (APT neutral file / CL-data) and existing CNC programs can be used to generate a valid new CNC program in just a few clicks for another machine using different kinematics and controller. This will enable manufacturers to adapt their existing programs to new resources when retrofitting a machine, buying a new one or when a machining process is repurposed.

If the target machine initially planned for the CAM program is no longer available for maintenance reasons or is already being used to meet production, it will take one click with NCSIMUL CAM to switch programming to another machine.

NCSIMUL CAM provides a direct access to 3D tool data and cutting conditions and automatically reconfigures the tool magazine. This will provide manufacturers with the level of flexibility they need to achieve rapid switching of scheduled production from one CNC machine to another, making their production means fully flexible and agile.