Norton Will Highlight Xtrimium Grinding Wheels During Motion + Power Technology Expo

Norton Xtrimium gear grinding wheels will be highlighted at the Motion + Power Technology Show Booth #2607, October 15-17, 2019 at the Cobo Center, Detroit, Michigan.

Norton ×€ Saint-Gobain Abrasives new Norton Xtrimium range of gear solutions designed for high performance gear grinding in extreme, tight tolerance environment earlier this year. The newly structured portfolio of gear grinding products is specifically designed by category to provide higher profile accuracy, supreme form holding and burn-free grinding in worm, profile, and bevel applications. Highlighting the new range is an innovative dual-worm wheel design that enables two operations in one grinding wheel, substantially saving time and cost.

“In today’s increasingly stringent industry requirements for higher accuracy and improved surface finishes, our new high performance Xtrimium grinding wheels are engineered to deliver the highest quality gear grinding solutions,” said Jim Gaffney, senior product manager, Norton ×€ Saint-Gobain. To download a brochure, visit (https://www.nortonabrasives.com/sga-common/files/document/flyer-wheels-geargrinding-xtrimium-8717.pdf).

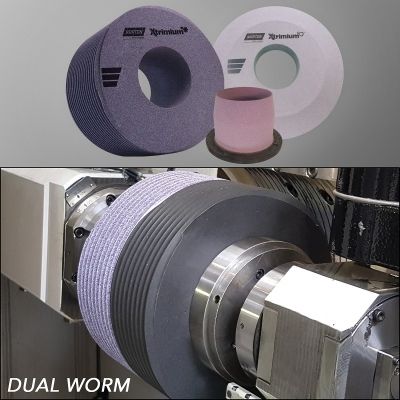

New Dual-Worm Gear Grinding Innovation Allows One Wheel to Grind & Polish

Norton Xtrimium Dual-Worm Grinding Wheels feature a unique design with a high-performance vitrified bond section for grinding and a fine-grit resin section for polishing the gear teeth, enabling one wheel to perform what traditionally required two wheels. Substantial savings in wheel costs and productivity via the elimination of wheel swapping, can be achieved with the Norton design. In addition, improved surface finishes of Rz = 1.0 mm and Rpk = 0.05 mm, and reduced harmonics (noise) are realized. The Norton Xtrimium Dual-Worm Grinding wheels can also be adapted to existing machines.

The Norton Xtrimium Gear Grinding Platform also covers the whole range of gear grinding processes and leverages the whole spectrum of Norton grains and bond technologies to match each customer's requirements, whether with:

•Worm Grinding Wheels featuring micro-structured ceramic grain and providing free cutting action and wheel homogeneity, allowing constant performance throughout the wheel thickness for the life of the wheel. Superior grinding rates and increased form holding without burn are achieved with these worm grinding wheels.

•Profile Grinding Wheels which are ideal for deep profile gear grinding. The wheels feature high porosity and permeability, create exceptionally high material removal rates, and friction-free grinding.

•Bevel Grinding Wheels featuring a highly porous bevel formation for extremely fast, burn-free cutting.

•Bevel Grinding Wheels featuring a highly porous bevel formation for extremely fast, burn-free cutting.