Nomenclature of Micropitting

Introduction

To understand a complicated subject, one needs to have a consistent and coherent system of nomenclature. It is the key to understanding the morphology and mechanism of micropitting. Unfortunately, it is typical for researchers to invent ambiguous terms for phenomena that are not well understood. It seems that the less we know about a failure mode, the more names we ascribe to it. This shortcoming is especially true for the complex phenomenon of micropitting.

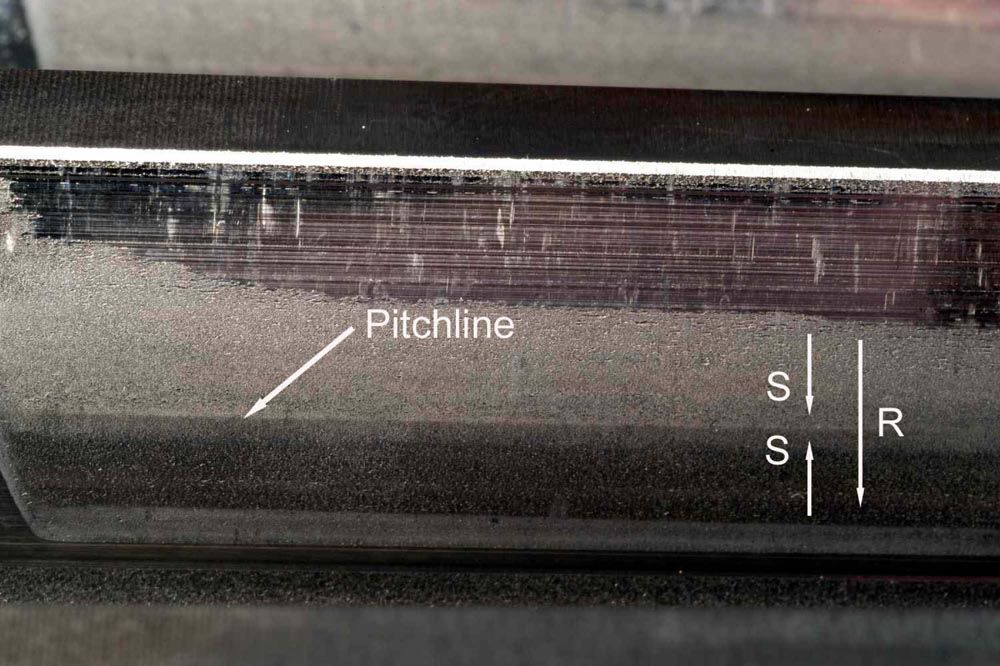

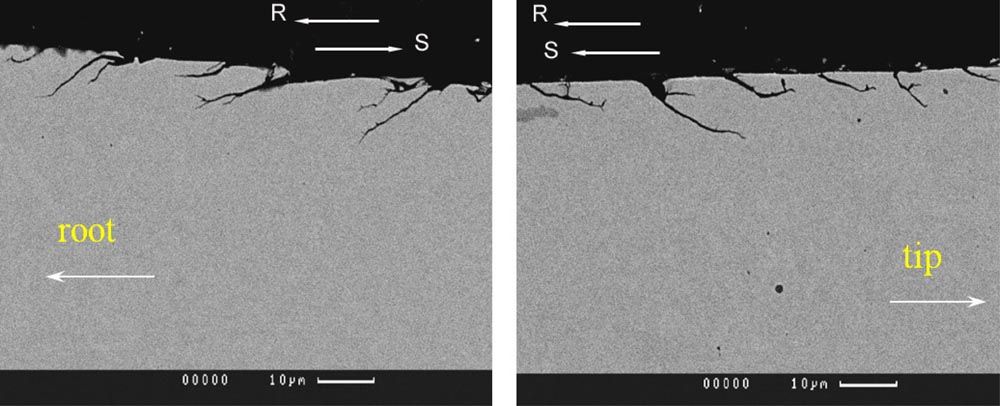

Figure 1 The image shows two polished metallurgical specimens cut transversely through gear tooth micropitting. The left shows the dedendum, and the right shows the addendum of the tooth of a driven gear. The vectors R and S indicate the rolling and sliding directions. Micropitting cracks start at the gear tooth surface and grow at a shallow angle (typically 10–30 degrees, but sometimes as steep as 45 degrees) to the surface. Image courtesy of Newcastle University.

Nomenclature

Tallian (Ref. 1) coined the phrase “surface distress,” which he later (Ref. 2) explained included micropitting. Tallian (Ref. 1) stated that the first sign of surface distress is a “burnished” appearance that is characterized by a “high gloss” of the metal and partial or total obliteration of the original finishing marks. He went on to say, “It is now believed that this appearance arises from plastic deformation of the asperities” and continued: “In a more advanced stage of this failure, small pits form on the burnished surface, which are at times aligned along ridges of the original asperities.”

In a later document (Ref. 2), Tallian introduced the term “glazing” when he stated that: “surface distress is attributed to asperity interactions causing plastic deformation (glazing) with subsequent microcracking and micropitting.”

In his Failure Atlas (Ref. 3), Tallian defined the early plastic flow stage of surface distress as glazing, and the later stage as micropitting. He describes a glazed surface as showing smoothing of asperity ridges into almost featureless flat areas (with valleys still discernible), possibly with some incidental wear marks or dents. In contrast, he states that under SEM magnification, microcracks opening to the surface may be visible in the glazed areas and describes a micropitted surface as appearing “frosted” to the unaided eye, possibly with barely visible black spots representing the micropits.

Incubation

Tallian’s early stage of surface distress is now confirmed to be the incubation stage for micropitting. In addition to Hertzian stress due to normal loading, sliding between gear teeth causes tractional forces that subject asperities to shear stresses. The first 104 to 106 cycles of stress occurring during run-in are an incubation period (Refs. 1, 12, 13) during which damage consists primarily of plastic deformation at asperities (Refs. 1–14). Spikes, Olver, and Macpherson (Ref. 12) give an excellent dissertation on the mechanism of the plastic deformation that occurs during the incubation period. Macroscopically, surfaces appear glazed or glossy (Ref. 12). Microscopically, surface asperities appear plastically deformed and original-machining marks might be partially or totally obliterated. Cyclic Hertzian and shear stresses accumulate plastic deformation on asperities and at shallow depths below asperities. The length of the incubation period depends on the relative hardness of the specimen and the mating components. Plastic flow produces tensile residual stresses (Refs. 10, 15) that increase the cyclic range of stresses that asperities are subjected to. With sufficient cycles, fatigue cracks initiate.