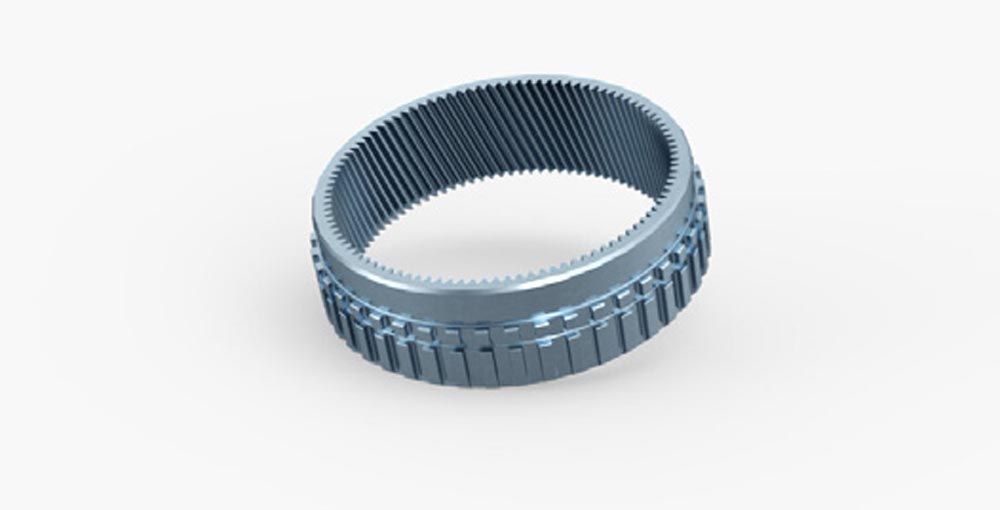

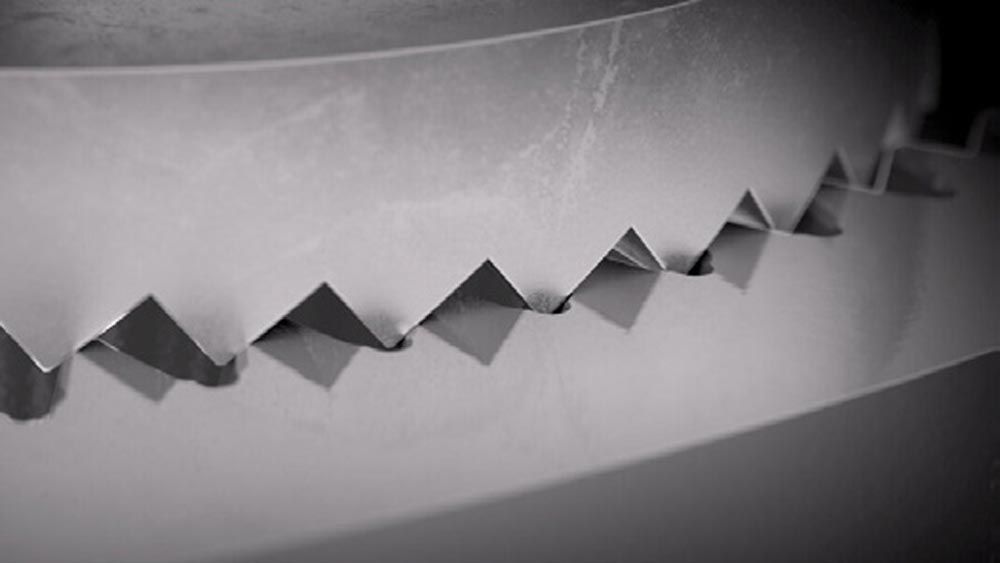

Figure 3a-3c—With VarioChamfer, a ring gear can be splined and deburred in a single clamping operation.

“This is where the VarioChamfer process plays to its full strength due to its space-saving tool.

Ring gears are internally geared components. As in the previous example, the burr occurs on the exit side of the gearing due to the cutting process. Here we have geometric limitations because this area is inside the clamping. Using a similar type of tool as for the stepped planet, collision-free immersion into the workpiece and chamfering is possible,” Painczyk said.

A particular advantage of the VarioChamfer process is that the workpiece can be deburred in the same clamping in which it was geared (see Fig. 3). It is not necessary to set it down and turn it over, which means no additional solutions are needed. The workpiece is deburred right after gearing.

VarioChamfer makes it possible to combine processes in the production lines on a small space, which saves investment costs for an additional machine. All processing steps take place inline in one machine. This is particularly important in the series production of transmission components. Thanks to VarioChamfer, for example, a stepped planet can be deburred in less than ten seconds.

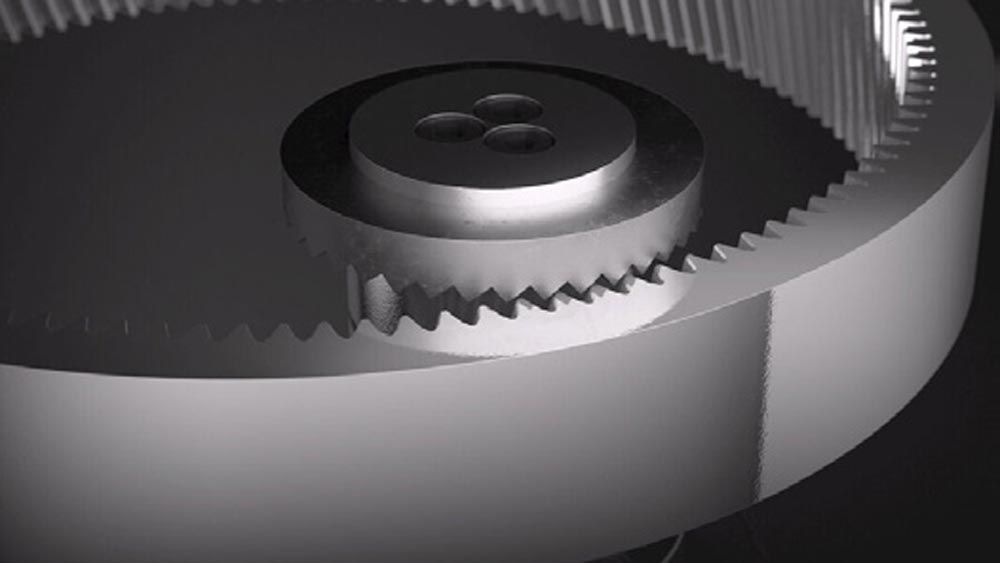

The concept underlying the VarioChamfer is based on the tried-and-tested backing milling process. This method enables the use of (usually conical) pockets in the tooth flanks. “VarioChamfer and backing milling use principles of kinematics, in which the movements of bodies are described purely geometrically with the variable’s location, time, speed, and acceleration: The circumference of the tool has a cutting edge which gradually plunges into every gap in the workpiece. This is generated by the axes of rotation, which are coupled at a fixed ratio. Breaking it down to a single axis, it can be imagined as follows: When you roll the wheel of a bicycle over the ground, the wheel’s valve points precisely downwards once every revolution. The path of the valve is always the same,” Painczyk said.

Now, if the ground is bent into a circle, after the wheel has rolled through the circle once the valve “immerses” at a different position than when it was rotated the last time. But the ratio between the wheel and diameter can be selected so that the valve always immerses at the same distance, i.e., where the imaginary gap is, added Painczyk.

dvs-technology.com/en/praewema-antriebstechnik

Future-Proof with Smart and Modular Robot Cells

Today, the ability of a company to compete in the future is largely dependent upon its efficiency and flexibility to adapt to shifting challenges – both are key strengths of the smart and modular robot cells from rbc robotics.

At the DVS Group, modularity is somewhat of a DNA building block. In the production process for electric motor drives, for example, Pittler's skiving, Buderus’s hard turning, and Präwema's gear honing technologies are combined to form an efficient turnkey process to produce high-end workpieces as needed in today’s modern drives. The modular robot cells from rbc robotics play a special role in this ensemble.

“Our customers’ requirements are constantly prompting us to push the boundaries of what is possible. Moving this “boundary of possibility” continuously over the course of two decades is what has made rbc robotics a leading solution provider of camera-guided robot systems. Today, the experience gained in well over 500 completed projects is reflected in the modular robot cells of the FX series,” said Dirk Hablick, division manager sales and project development, rbc robotics.

Key to future-proof and flexible automation are industrial robots combined with the latest 2D/3D sensors for capturing the position of the components. The modular system enables the seamless combination of individual robotic modules and thus facilitates compact production concepts. A very important aspect of future viability!

Figure 4—Industrial robots combined with the latest 2D/3D sensor technology for capturing the position of components will be key to flexible automation in the future.

“The modularity of the robot cells from rbc robotics enables more than just the optimal connection of individual robotic modules: as an automation module, the systems are also an excellent match for the CNC machines from the DVS Group and thus ensure a perfectly coordinated overall production and machining process,” Hablick added.

In real production environments, the robot parameters change constantly due to the different sizes, geometries, manufacturing tolerances, and surface characteristics. Thanks to tried-and-tested image recognition solutions, the automation cells from rbc robotics can conquer the next frontier: they are able to see and grip workpieces more precisely and efficiently than ever before.

“Today, almost all industries are affected at all levels by labor shortages, from highly specialized professionals to helpers for simple tasks. And for demographic reasons alone, that will not change any time soon. One of the solutions to this problem is smart, flexible, and camera-controlled robot systems that require minimal space and are very powerful. They are also easy and intuitive to operate and adapt to different components with a high degree of flexibility,” Hablick said. “So modular, smart automation solutions create continuity, efficiency, and flexibility in production, which means security in the future. And finally, modularity ensures that any solution can be very individually adapted to specific circumstances and challenges.”

dvs-technology.com/en/rbc-robotics

Regarding tool technology

In addition to the traditional and rather quantitative characteristics of tool performance, such as the service life and throughput, today there are additional, high qualitative requirements: modern drive technologies require gears with extremely fine surfaces and complex micro-geometries. This new generation of workpieces can only be achieved with high-end tools, such as the Vario Speed Dressing technology from Präwema SynchroFine in combination with high-performance honing rings from Naxos. So, it could be said that modern tool technology is the enabler of future-oriented technology.

Integrated solutions

Working together synergistically has long been a guiding principle of our Group. We optimally coordinate technologies, materials, and services and deliver virtually seamlessly integrated processes to our customers. On a day-to-day basis, our customers also notice this in terms of their single point of contact, who has an overview of the entire DVS realm, from machine issues and tool supply to process optimization. These integrated solutions are certainly also the reason why the Präwema honing machine and the specially matched DVS honing tools are market leaders.

Digitalization

Digitalization is par for the course from the manufacture of tools to their controlled and documented use. Recording the service life and process data is pivotal to maximizing process optimization and thus enabling our customers to save costs. I’m certain that AI will continue to accelerate this process in the future or enable it in the first place. The future of the tool industry is inconceivable without digitalization, digital services, and digital innovation like DVS Connect.

New materials

New materials play a decisive role both in terms of the workpiece and the tool. For example, look at the brake discs that are mandatory in all new cars from 2025: extremely hard and never-before-used materials are used here. This means the tools used for processing these brake discs must also perform at an entirely different level. Some of these requirements can only be achieved with new types of tool materials. And so, the circle of constantly increasing quality closes.

dvs-technology.com