The Future Looks Bright for the Gear Inspection Industry

Empowering quality through deeper precision

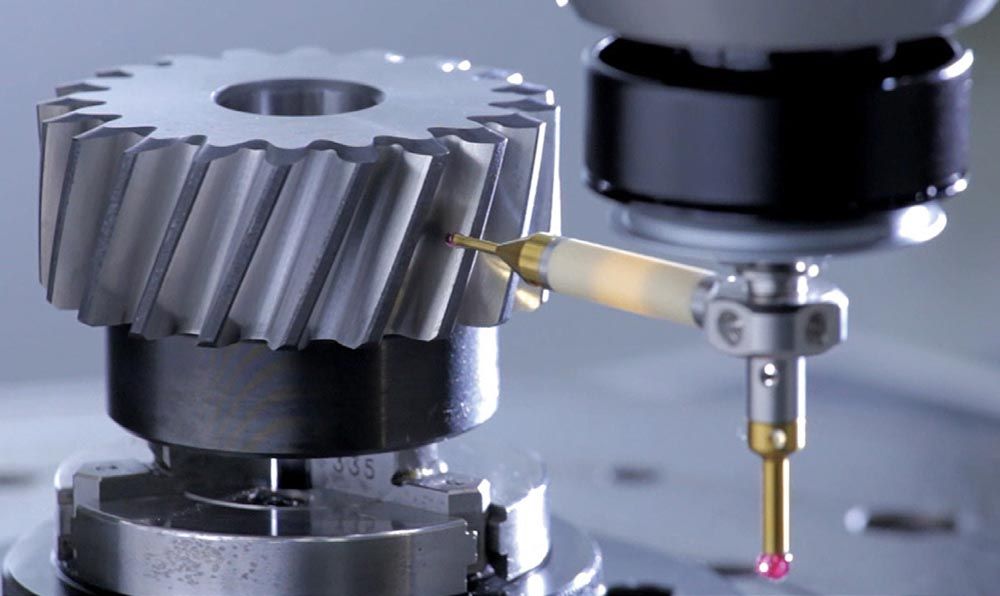

New technology in CMM probes allow for touch probes to measure gears with high accuracy and repeatability.

On the surface, it may not seem like the gear inspection industry has changed much over the last few years. Shops still primarily use either machines that are dedicated solely to measuring gears, or multiuse Coordinate Measuring Machines (CMMs). And regardless of which machine they use, software serves as the backbone that supports their many diverse sensors.

Despite the turbulent economy of the last few years, the gear manufacturing market is expected to grow at a fairly modest CAGR of 5.73 percent through 2026, according to Technavio. As the industry expands, more gear manufacturers are streamlining and automating the inspection process with multisensor CMMs.

But underneath the surface, several exciting and innovative developments are driving the gear inspection industry forward. These bright spots have the potential to transform not only how gear inspection is conducted, but also the tools and processes that companies use as well.

Bright Spot #1: CMMs

While not new, CMMs continue to be a game changer in the industry. Combining multiple gear inspection and measurement tools into a single platform is a highly attractive feature for businesses, and provides several time- and cost-saving benefits:

- Improved quality: CMMs help create higher-quality gears by eliminating operator error. Since the engineering CAD model automatically generates the inspection program, the results are clear and unambiguous, nor are they subject to different interpretations by an operator. Additionally, automated optical tools don’t touch the gear, ensuring that high-precision measurements can be taken without damaging the gear’s precision surface.

- Improved costs: High-end, automated, programmable, and dedicated gear-checking equipment can cost hundreds of thousands of dollars. You also need to account for the additional costs of master gears and the artifacts. All told, that equipment can be two or three times more expensive than a multisensor CMM equipped with a rotary table, high-speed scanning probe head and gear measurement software.

- Improved productivity: Perhaps the greatest advantage of multisensor CMMs is that they save a significant amount of time since they measure several characteristics faster and more accurately compared to manual methods. And with shops pressed for time more than ever before, this benefit can’t be overstated. Whether used for gear checking or regular SATIC geometry, CMMs can provide a 30 percent to 98 percent time savings. The amount of time saved actually grows as the complexity increases. Multiple functions—such as gear parameter inspection, microscopic gear teeth measurement and high-accuracy 3D scanning—can all be done on the same machine. And by using a surface probe, you can check the surface and finish of gear teeth, the internal bore of a gear, as well as the mounting and shaft.

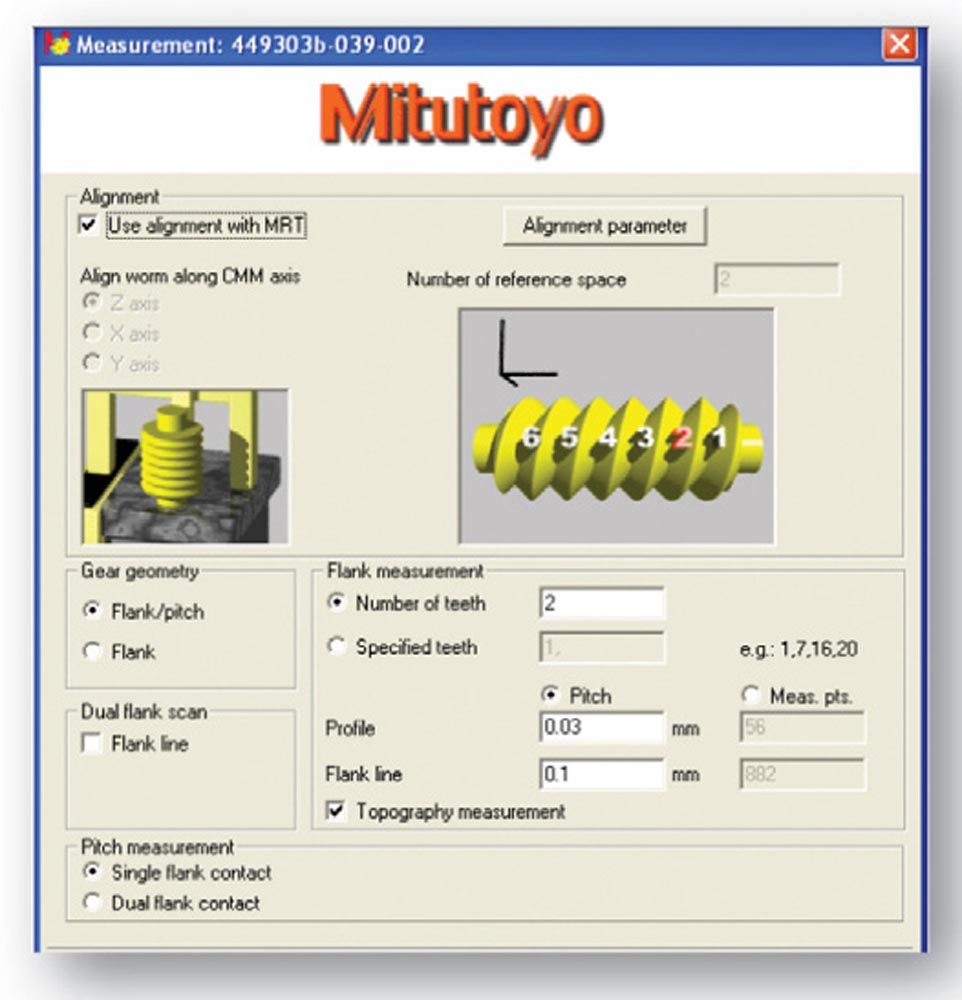

Special CMM software supports measuring different types of worm gears using a touch trigger probe or scanning probe on a CMM.