These cobots offer several advantages over traditional automated systems in terms of safety, quality control, accuracy, reduced labor requirements, shorter lead times and more.

4. Automation and the Skilled Workers Gap

The skilled worker shortage seemed to take an even bigger blow during the pandemic. Shop floors that need to run three full shifts to keep up with production demands can’t find the personnel necessary to do the job. They may not need to worry about this in the future thanks to automation and mobile data communication.

When these robots are working in factories during second and third shifts, shop floor personnel will be on call via a smartphone, tablet, or desktop computer, but will not have to be onsite unless an issue occurs. Fundamentally, this is where automation and robotics can be the most helpful according to companies such as PBC Linear, Festo and SEW Eurodrive. Lights out manufacturing will continue to gain momentum in the coming years as job shops find more affordable technologies that mirror larger OEMs smart factory strategies.

“We've consistently had more than 800,000 open manufacturing roles nationally for quite some time. And it's going to be really difficult, even with perfect recruiting efforts, to close the gap. So, I think the biggest opportunities with automation are this: it's going to enable the same size workforce to do more. And in this moment, I call it “glocalization,” where we have supply chains that are regrowing U.S. manufacturing more is certainly needed. We need more scale, more speed, more sustainability, and now we have all the tools we need to deliver those,” said Barbara Humpton, president and CEO, Siemens Corporation USA in a Q&A with the Automate Team.

5. ChatGPT isn’t Taking Over…Yet

AI is on everybody’s minds except the robots! Seems like every presentation at Automate had a question or two regarding the fear and trepidation of artificial intelligence in 2023. Even James Cameron is waiting to see how AI innovations “shake out” before tackling another Terminator film.

Is there real cause for concern? Robert Huschka, vice president at A3, moderated two fascinating panels including “What ChatGPT, Large Language Models and Other AI Advances Mean for Industrial Automation.” Panelists included employees from GM, NVIDIA, GE Research, and Microsoft. The second, “Executive Roundtable: The Future of Robotics & Automation in North America,” included panelists from Siemens, ABB, Fanuc, and FedEx.

Panelists discuss “What ChatGPT, Large Language Models and Other AI Advances Mean for Industrial Automation.”

Panelists discuss “What ChatGPT, Large Language Models and Other AI Advances Mean for Industrial Automation.”

Huschka asked both panels how soon the manufacturing floor would mirror the Tony Stark, Iron Man, robotic assembly process where he’s talking to the AI system that is manufacturing his latest suit of armor. Both panels agreed that while we’re not quite there yet, there are areas where AI can improve production processes.

Examples of AI products at GE Research include reduced downtime on assets through AI-driven proactive intervention (for e.g., airline delays and cancellation), increased throughput (for e.g., optimal control of wind turbine settings to maximize farm output), or reduced costs (for e.g., optimal power plant operation to minimize fuel costs).

“I think there’s a lot of opportunity for AI to be incorporated into current and existing applications,” said Bubnikovich at ABB Robotics. “We’re just on the cusp of new AI applications. Five years ago, we started to see picking and vision advancements, but in terms of generative AI there must be a need where it provides value.”

“Robots are only going to do what we program them to do,” added Mike Cicco, president and CEO, Fanuc America Corporation. “In the case of ChatGPT, it just has a very big brain and can see all these other documents, but when you ask it a question it just pulls from every other document it’s using.”

Johan Reiman, principal scientist, AI and machine learning at GE Research, summed it up by suggesting to the audience to be skeptical about ChatGPT. We should always ask questions, try out the technology ourselves and be mindful of its advantages as well as its limitations.

6. Consider Every Automation Format

Articulated robotic arms are typically the showcased technology in manufacturing automation, but the field is growing and changing at a rapid pace. Modern linear transport systems, for example, move parts and products and can assist with adapting production machines for rapidly changing production lots.

Jeff Johnson, mechatronics product manager at Beckhoff Automation, discussed how mechatronic transport systems can offer advantages over traditional robotic automation. This includes the ability to create a mobile handling system, heat or cool products during transport or integrate data communication for condition monitoring and predictive maintenance.

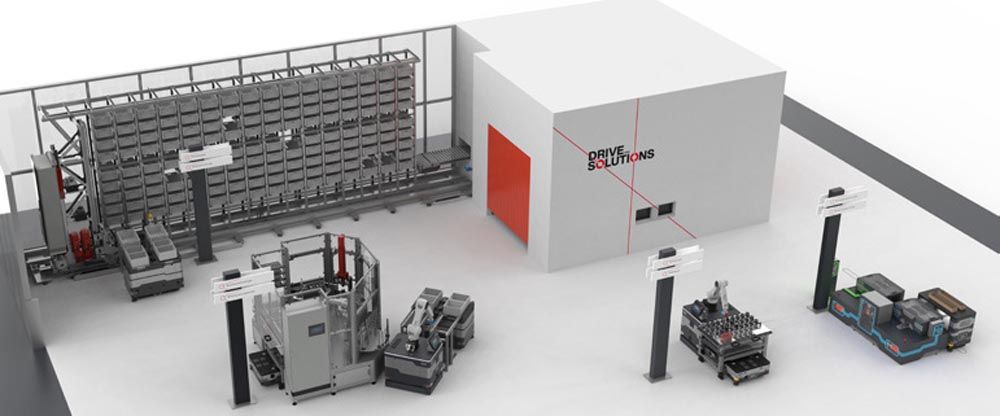

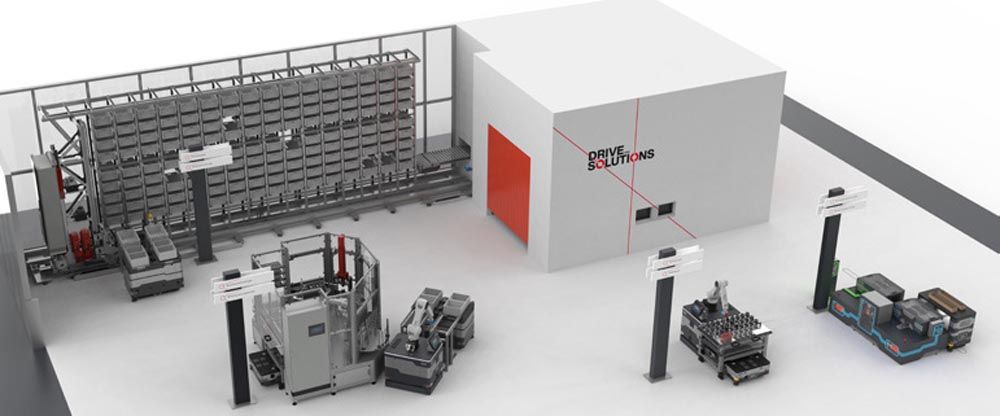

The Maxolution process modules from SEW-Eurodrive offer insight into what tomorrow's world of adaptable production could look like. Performance benefits can be achieved with the aid of supporting automation and future-proof material flow and logistics concepts.

The story of the production process starts at the small parts warehouse. The solutions for the storage/retrieval systems come from the MOVI C modular automation system. From drive technology, control technology, and safety technology to software and visualization, SEW-Eurodrive offers everything from a single source and to suit the relevant application.

An automation model suggests what the factory of the future might look like from SEW-Eurodrive.

7. Robot Demand is Increasing

The Congressional Budget Office recently forecast that the size of the US labor force will grow by just 0.2 percent annually from 2024 to 2031, and by 2030, it is predicted that more than 2.1 million U.S. manufacturing jobs will be unfilled. This will hamper economic growth and present companies with the need to find new ways to plug gaps in the workforce.

Demand for robots will be particularly strong in countries where companies are planning to re- or near-shore their operations to help improve their supply chain stability in the face of global uncertainty.

In a survey of 1,610 companies carried out by ABB Robotics in 2022, 70 percent of US businesses said they are planning to re- or near-shore their operations, with 62 percent indicating they would be investing in robotic automation in the next three years.

“While much of the mainstream attention has focused on the impact of automation taking jobs, robots will increasingly perform the physically stressful tasks that people are reluctant to perform, helping to moderate industrial and commercial labor shortages,” said Bubnikovich. “The continuing advancements in ease of use and flexible performance of robots, including the development of collaborative models with larger payloads such as ABB’s GoFa and SWIFTI cobots, mean companies can address skills gaps and make better use of their existing workforces.

8. Stay the Course

Conviction. Conviction. Conviction. If the universe throws a pandemic your way, a skills shortage, a raw material treasure hunt or six months just doesn’t go by the books, the lesson here is simple: Keep on keeping on!

If Gregory Robinson, former director, NASA, James Webb Space Telescope, can overcome an exorbitant number of obstacles and challenges—including COVID—to successfully spearhead an astronomy project that was way over budget and years behind schedule, it’s possible to get to the finish line of any venture.

“I didn’t even want the job at first,” Robinson said during a keynote address at Automate. “I was enjoying my job as deputy associate administrator for programs at NASA. They had to twist my arm a little.”

Gregory Robinson, former director, NASA, James Webb Space Telescope, addresses the crowd during his keynote presentation at Automate 2023.

Gregory Robinson, former director, NASA, James Webb Space Telescope, addresses the crowd during his keynote presentation at Automate 2023.

With the heavy burden of getting the James Webb Space Telescope program back on track, Robinson celebrated the men and women on the team by prioritizing relationship-building, creativity, knowledge-sharing and understanding the importance of successful collaboration.

Listening to his address at a show full of robotics, automation, and motion control, it was ironic how important the human element still is to achieve any manufacturing and engineering goal despite being surrounded by cobots, AMRs and drones.

Automate 2024 will take place May 6–9, 2024, at McCormick Place in Chicago.

automateshow.com