ARGUS “Swarm-Based” Gear Grinding Expertise

A process and machine component monitoring system

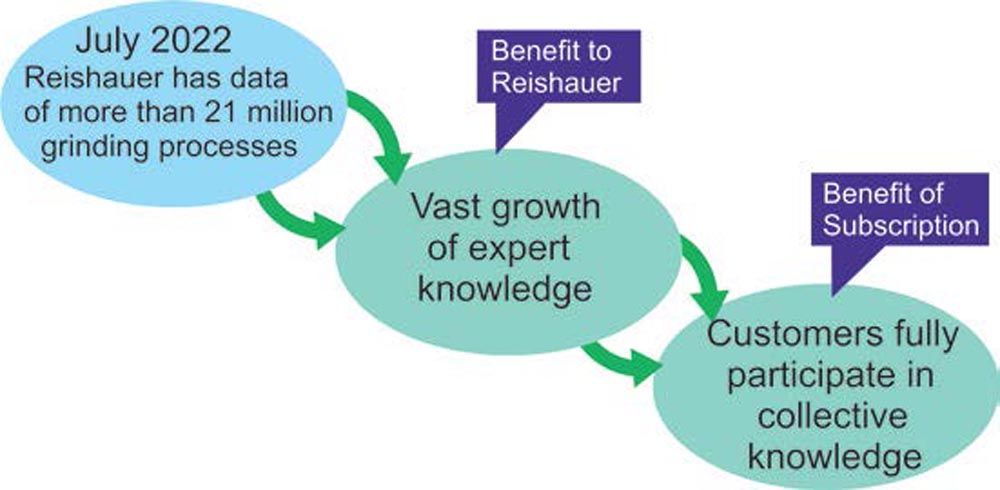

This article describes a cloud-based process and machine component monitoring system called ARGUS. The term “swarm” is used for a large population of gear-grinding machines of individual and independent customers connected to the ARGUS system and the ARGUS cloud. These “swarm” machines permanently feed their anonymized process data into a common cloud database. Reishauer uses this database for big data analytics to discover patterns that indicate successful process and machine component behavior patterns worth integrating into the ARGUS algorithms and propagate them across the complete ARGUS customer base. Of course, should the system also discover detrimental process patterns, such patterns are eliminated by adjusting the algorithms accordingly. While the system can operate as a standalone version at one customer plant, and even if this customer had some 50 machines, their data would never suffice to gain the insight that the much larger cloud-based Reishauer database can. First, an individual customer does not have the range of workpieces that would be stored collectively in the ARGUS cloud. Second, individual customers, for better or worse, have their ideas of an efficient grinding cycle. Within a large group of customers, there are always those who push boundaries and may discover new approaches which, once proven by ARGUS, would enrich the data to benefit all subscribers. This article argues that using the cloud-based variant, which is subscription-based, offers many benefits to individual customers. As a subscription to ARGUS entails automatic updates containing all insights gained, the subscriber constantly benefits by safely making full use of the grinding machines’ potential by grinding close to the top performance limits.

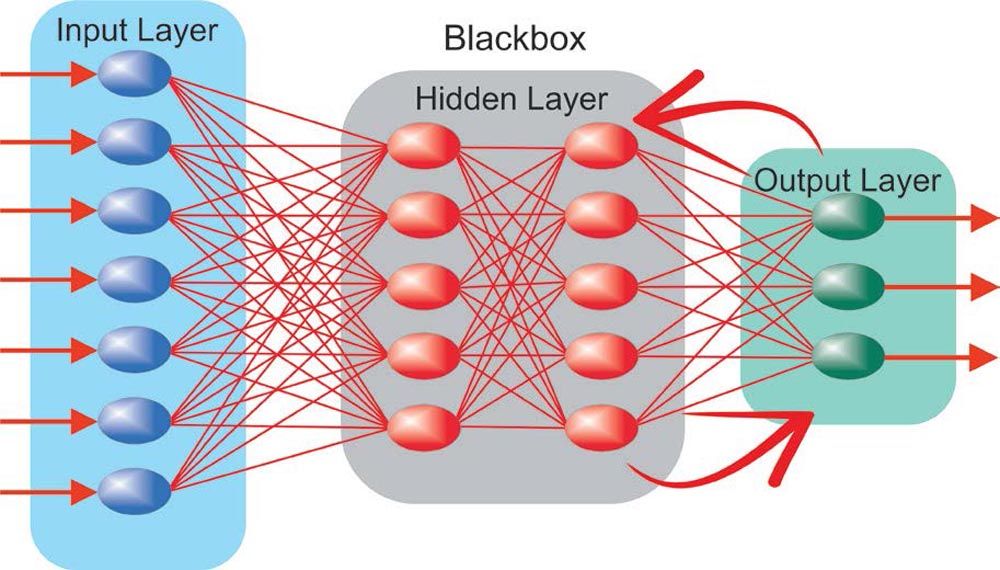

Reishauer is continuously expanding its knowledge base. In July 2023, Reishauer already had around 21 million grinding cycles and stored all the associated data points. Moreover, every one of these 21 million cycles encompasses around a million data points each. At this point, it is important to repeat that all the data is anonymous and not linked to any specific customer. With complete parameter data, twenty-one million grinding operations is a large enough data pool to apply Data Science and use artificial intelligence (AI) for pattern recognition and adaptation of algorithms.

These data sets provide tremendous insights into processes with different grinding parameters. For example, Reishauer can gain insights into the optimal setting of grinding intensity limits. At the same time, the individual data sets remain anonymous, which is important for our customers and Reishauer. However, any general insights Reishauer gains from analyzing the data can be continuously fed into ARGUS updates. This way, all the subscribed customers gain a deeper knowledge of the generating grinding process.

Figure 1—Benefits of large database model.

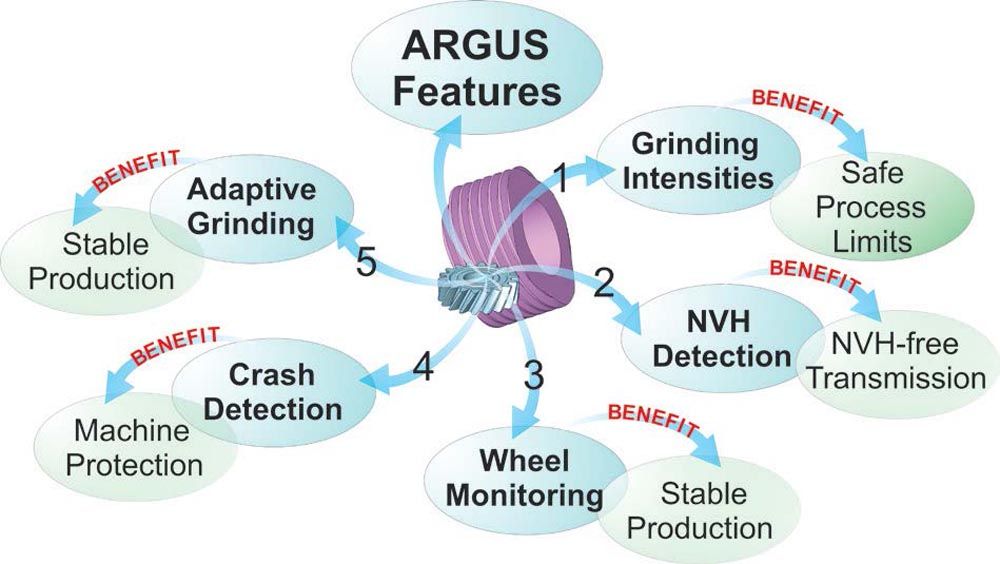

ARGUS Features

1» Grinding intensities:

[advertisement]

These parameters are based on a force model describing the Reishauer process’s contact condition. Once the grinding intensities of the roughing and finishing process are established, the parts ground within the limit have been proven accurate. In line with the quality requirements, all subsequent parts that are ground within the grinding intensity limits are also acceptable. For example, faulty pre-machined parts would generate grinding intensities that exceed the limits, and the Reishauer machine would automatically identify these parts and remove them from the process. This feature allows 100 percent part-quality control. 2» NVH detection: ARGUS has proven invaluable in detecting and preventing NVH issues. In the best case, ARGUS can detect parts using spectral analysis that may generate NVH once they are put into transmissions. In a second case, ARGUS can be used—via Automatic Component Monitoring or analysis of the grinding data—to pinpoint the origin of the NVH problem. 3» Grinding Wheel Monitoring: In the past, individual operators assessed grinding wheels subjectively. ARGUS offers a clear analysis and monitoring of the performance of a grinding wheel across its full tool life. 4» Crash Detection: This ARGUS safety feature protects the machine tool. If, for example, a workpiece bore is too big and, consequently, cannot be clamped properly, it may move its position. When meshing with the threaded wheels, the out-of-position workpiece may collide with the threaded wheel. However, as ARGUS instantly picks up excessive grinding intensities, the machine immediately retracts into a safe position. This feature also protects the threaded wheel and ensures that only little damage on the threaded wheels occurs and can be easily dressed off. 5» Adaptive Grinding: Adaptive grinding is an effective way of stabilizing the grinding process if the pre-machining is low quality. Varying material allowances and heat treatment distortion often lead to nonlinear and unstable contact conditions. An adaptive grinding process maintains the grinding forces constant, offers safety against overload, and reduces tool wear. |