Kapp Niles Provides Digital Solutions for the Closed Loop

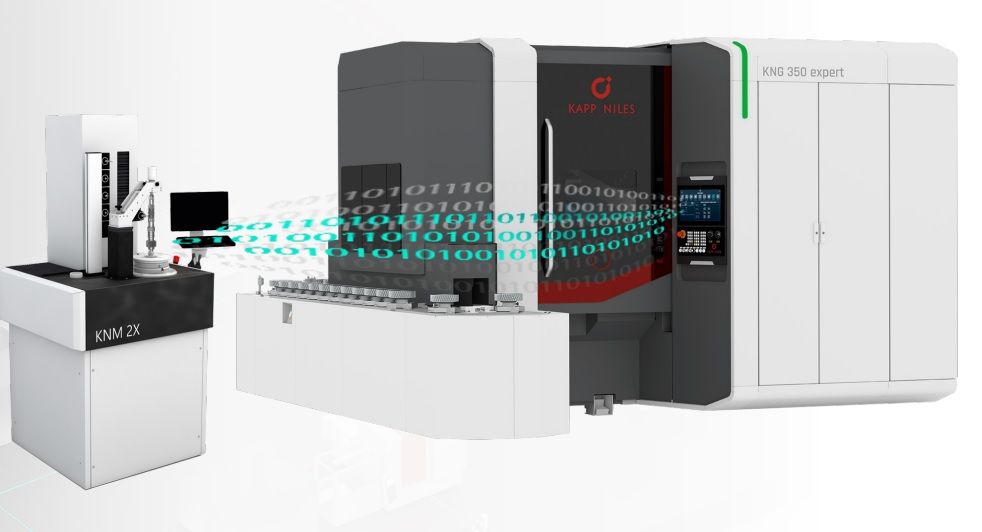

With Closed Loop, Kapp Niles offers a system that enables the integration of machining and measuring machines. By using Closed Loop, efficient processes and optimized production are realized. This tool helps companies to improve the quality of their workpieces and to make their processes more efficient. With automated corrections, it significantly reduces the reject rate. Furthermore, Closed Loop is flexible and compatible with machines from other manufacturers, which makes an investment in a new infrastructure unnecessary.

The Kapp Niles system offers standardized transmission via GDE (Gear Data Exchange) of correction values, including parameters such as profile angle deviation (fhα), flank

line angle deviation (fhβ), tooth width, ball dimension and two-ball dimension (Wk). Through seamless integration into existing processes, Closed Loop enables different machine types to work together efficiently.