Jergens Adds Adaptix Vise Jaws for Versatile Part Holding

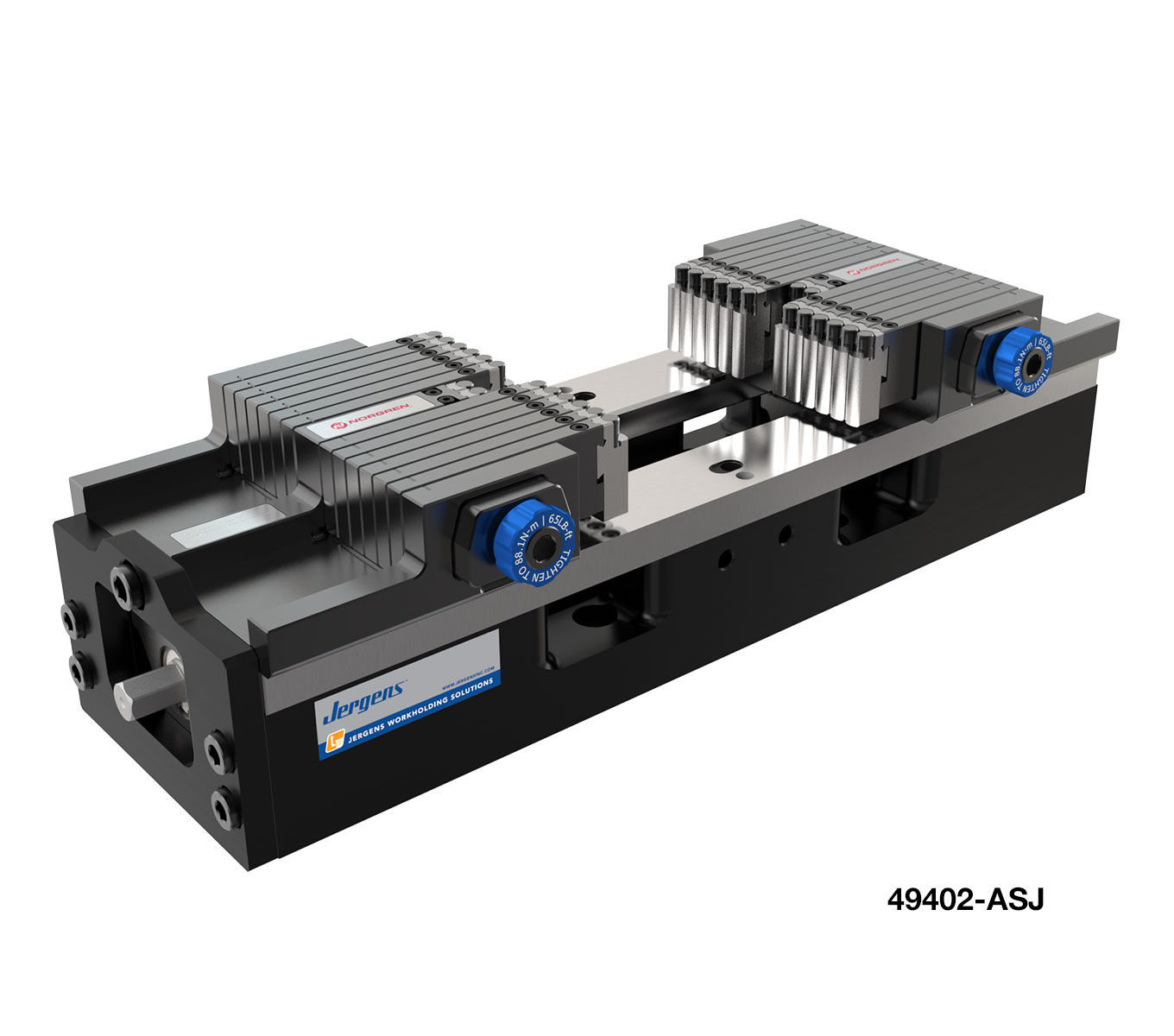

Jergens partners with Norgren to engineer the Adaptix vise jaw system into its line of production vises. The unique design – which incorporates sliding fingers with replaceable studs and fingertips – clamps challenging workpieces quickly and securely for machining. With this, Adaptix is mounted to the vise body in place of standard jaws to accommodate part configurations, adapting to asymmetrical and other features quickly.

The high gripping force ensures precision throughout the machining process. Once the lockable fingers have been adjusted to the workpiece, which takes only moments, the remaining parts are clamped in and out quickly and with high repeatability, resulting in more uptime and tight tolerances. Because these shapes can be set up very fast, Adaptix is well-suited for high-mix, low-volume applications including short production runs and prototyping. The moving parts of the jaws – fingers, studs, and fingertips – have been engineered for many thousands of actuations and are also easily field serviced if needed.

Adaptix offers a productive solution where soft jaws leave off. Often a choice when holding workpieces with unusual features, soft jaws perform well but require, among other things, a longer time to set up. In some cases, that is upwards of two hours, whereas Adaptix requires an average of approximately 20 minutes and offers superior accuracy and repeatability. Additionally, this flexible system reduces the need for multiple soft jaws, helping to lower overall tooling inventories and associated costs.

Adaptix is designed so fluids and chips won’t interfere with operation. The system’s studs are available in different materials including aluminum and steel. Step profiles and other shapes provide gripping flexibility. The jaw system is compatible with industry vises such as Jergens 6” production vise. Packages with vise and jaws, or Jaws only, are available.