Characterization of the Gear Meshing Damping of Gear Drives with Plastic Gears Using the Forced Response Analysis for NVH Prediction

In powertrain systems, all deformable elements can dissipate energy when subjected to dynamic deformations. The internal damping of these elements including bearings and supports, shafts, and gears have an important impact on the energy dissipation. Consequently, damping plays an important role in the design of structures to minimize noise, structural instability, and fatigue failure of components. The gear meshing damping is known as an important determinative factor in the dynamic response of the system under specific running conditions. Without damping, undesirable induced vibrations create noise, increase dynamic loads, and potentially damage the gear teeth and bearings. It is well-known that plastic materials have higher damping values than steel. So, the main question discussed in this paper is, how noise, vibration, and harshness (NVH) are influenced by the presence of different viscous gear meshing damping. Here, some guidelines are presented to adjust the gear meshing damping for achieving the NVH characteristics of a powertrain system. In this regard, a dynamic calculation process called “forced response analysis tool” has been developed in KISSsoft to enable analysts and engineers to perform the dynamic analysis of the powertrain systems quickly and efficiently (Refs. 1, 2). To achieve this goal, gear body material with higher damping properties within the required torque ratio specifications can be chosen. Based on the static transmission error of the gears, shaft imbalances, etc., the bearing reaction forces are calculated by considering their mass and inertia.

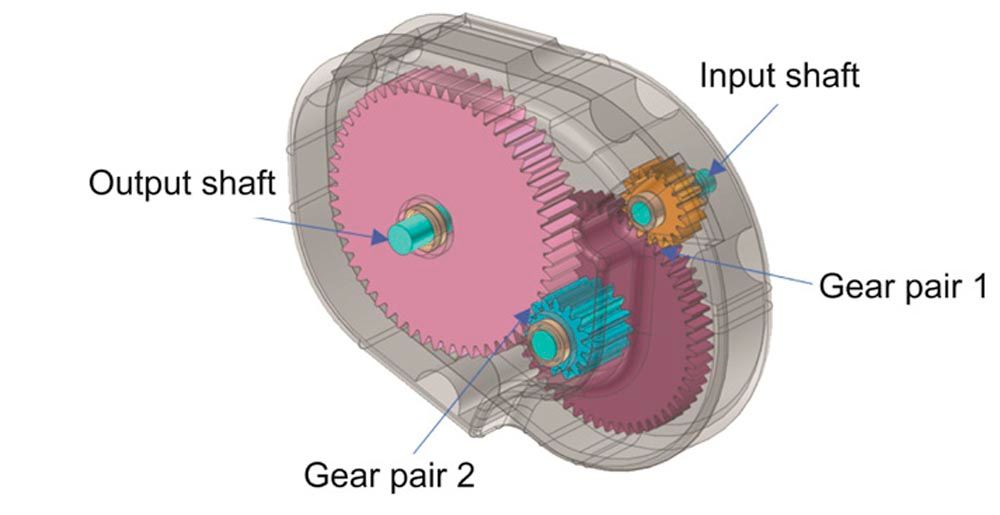

Figure 1—A two-stage gearbox model layout.

Forced Response Analysis

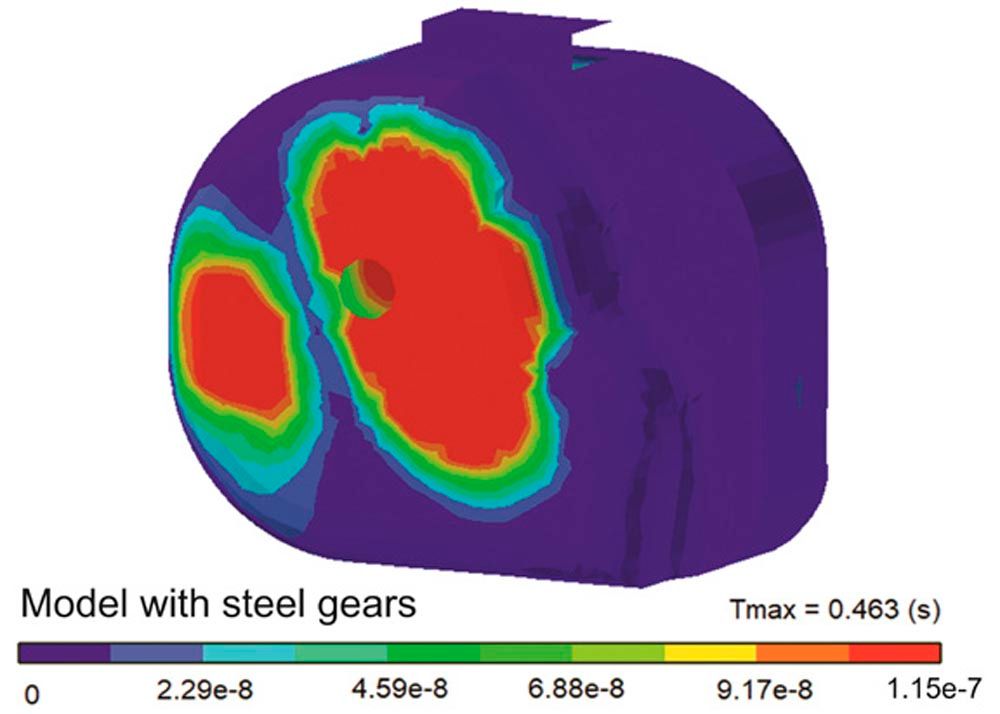

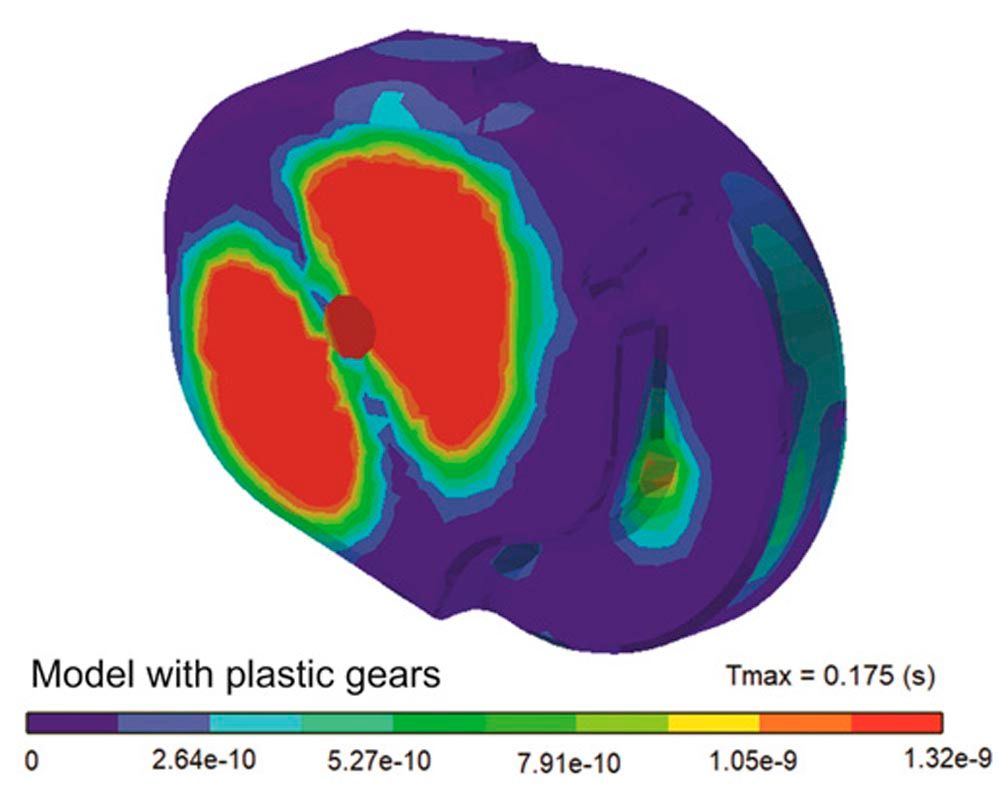

A two-stage gearbox model is considered in two variants with different gear materials, one with plastic gears and one with steel gears, see Figure 1. Both variants have the same input parameters (load, speed, number of cycles) and are designed to have similar root and flank safety. Therefore, the plastic gears are larger and have bigger diameters. The plastic gears’ strength is calculated according to VDI 2736, while the steel gears’ strength is calculated using ISO 6336. Both variants have the same housing material. Based on the load excitation imposed by the gears, the forced response analysis is conducted and at the bearing positions, the transient loads are evaluated.

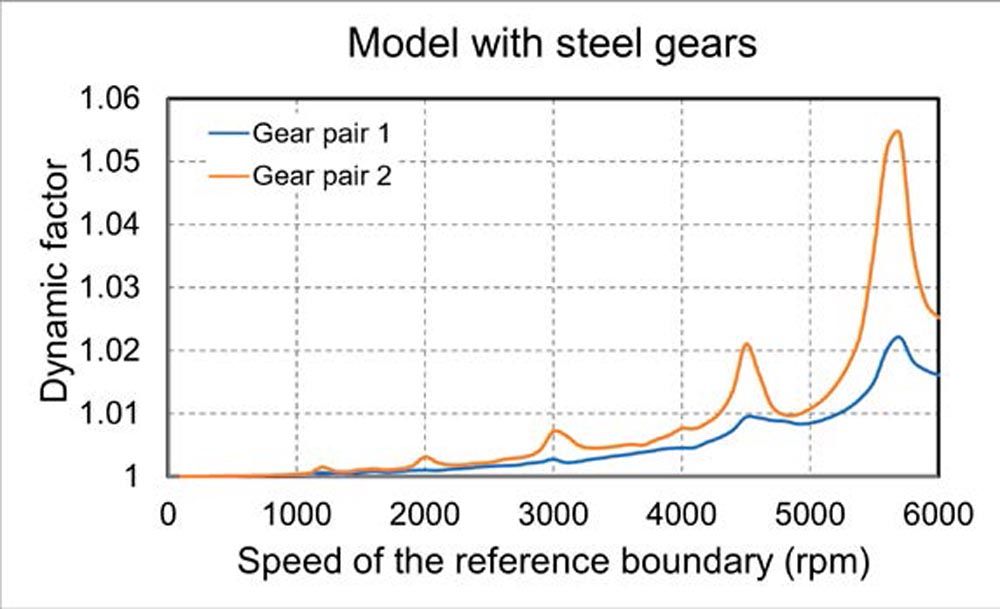

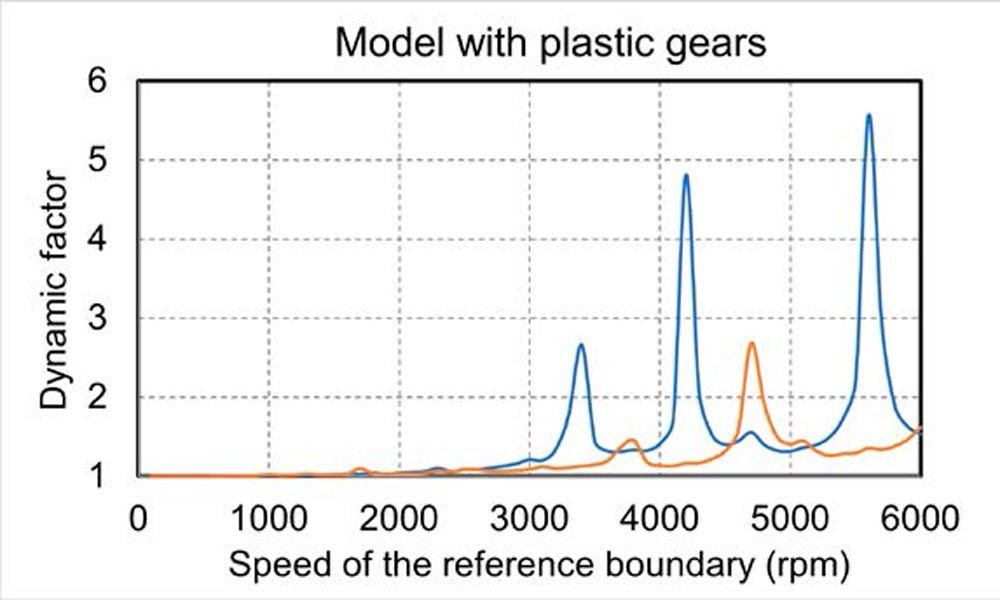

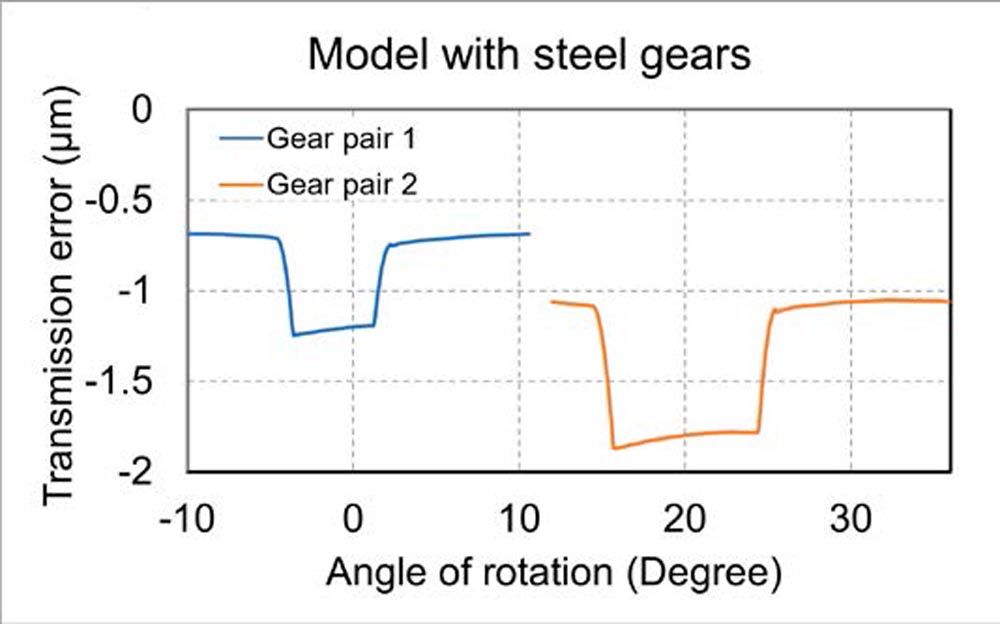

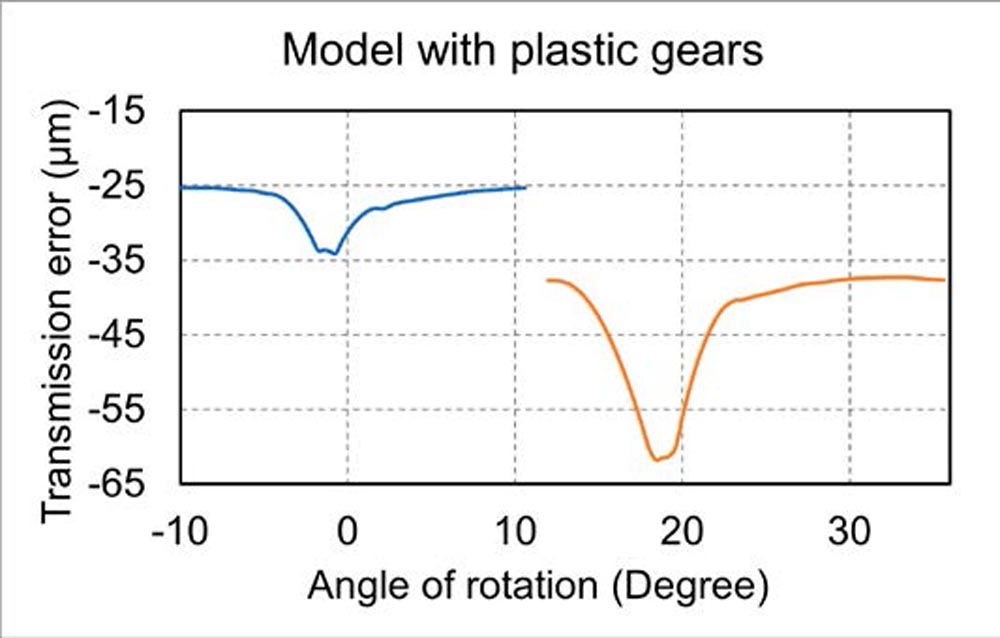

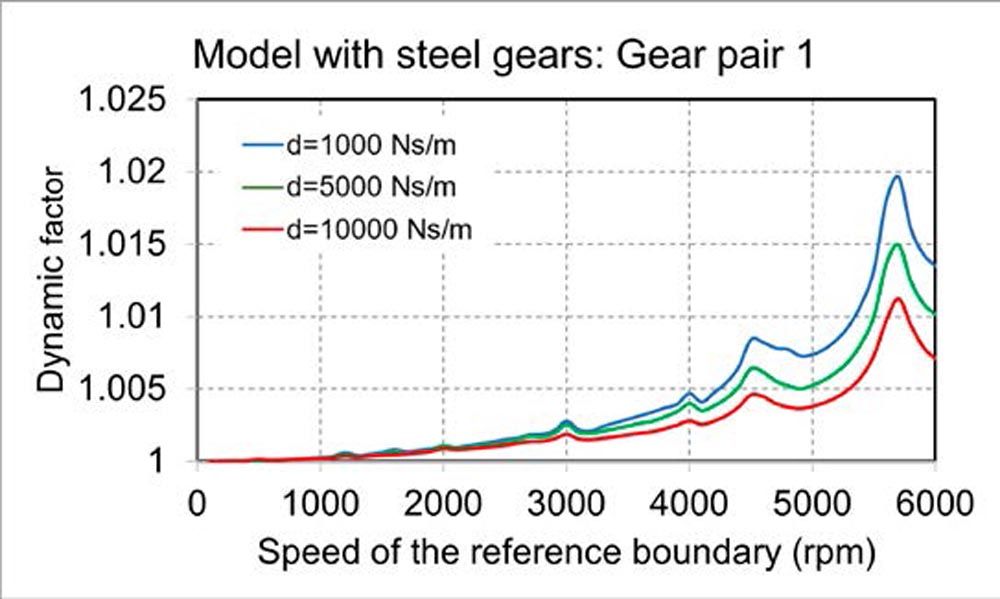

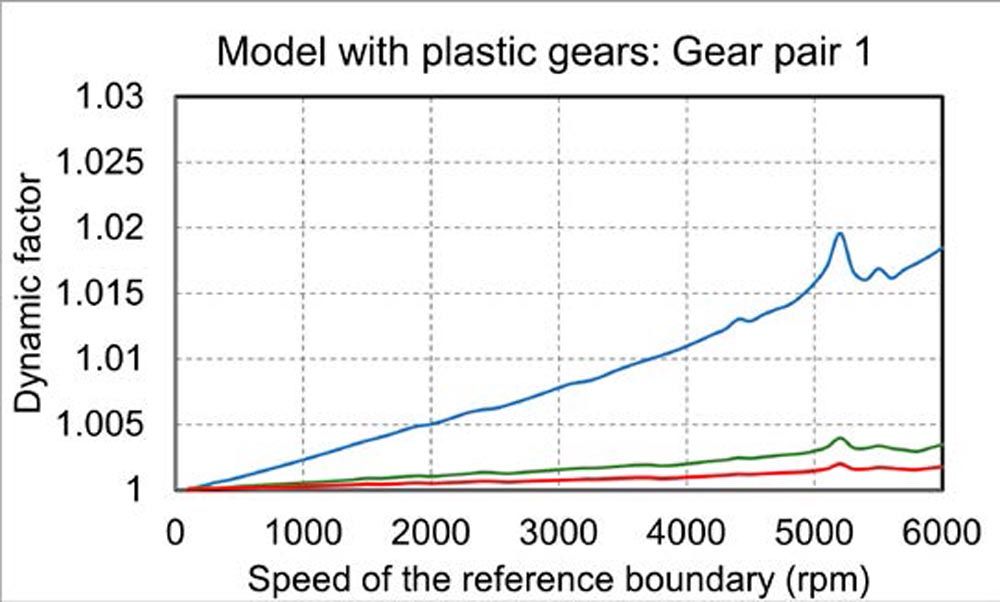

In the first step of the forced response analysis, the dynamic factor Kv is evaluated. The dynamic factor is the ratio of the maximum dynamic excitation load between the meshing gears to the static contact force. Kv of the first gear pair of both models without gear meshing damping is shown in Figure 2. The dynamic factor characterizes the system behavior under dynamic loading at different shaft speeds and reveals the margins of the operational speeds for which the powertrain system can be significantly excited. The increase of the dynamic factor in the model with plastic gears is much higher than in the other model when no gear meshing damping is considered. The main reason behind this difference is the high transmission error due to the low meshing stiffness of the plastic gears compared to the steel gears, see Figure 3. In the example used, the dynamic meshing forces of the plastic gear model without damping consideration increased up to 550 percent (Kv=5.5); whereas in the steel gear model, the increase is only about 5.5 percent (Kv=1.055) (Fig. 2). When we first obtained these results, we were searching for errors in the calculation approach, as—from practice and test rigs—we know that gear drives with plastic gears have lower excitations. However, the results changed completely when we rerun the calculations considering damping.