Blaser Examines Every Chip in Detail in an Innovative Series of Tests

The macro high-speed recordings are impressive: Viewed in slow motion, a carbide milling tool removes a perfectly shaped brass chip. The Blaser Synergy 735 metalworking fluid becomes cloudy around the curling chip—exactly where the heat is greatest. It leaves an oil-like phase and thus forms an even more effective lubricating emulsion. In an extensive series of tests in the in-house Technology Center, the metalworking fluid experts from Blaser Swisslube analyze machining processes down to the finest detail. The principle: To achieve better metalworking fluids faster through expertise and data.

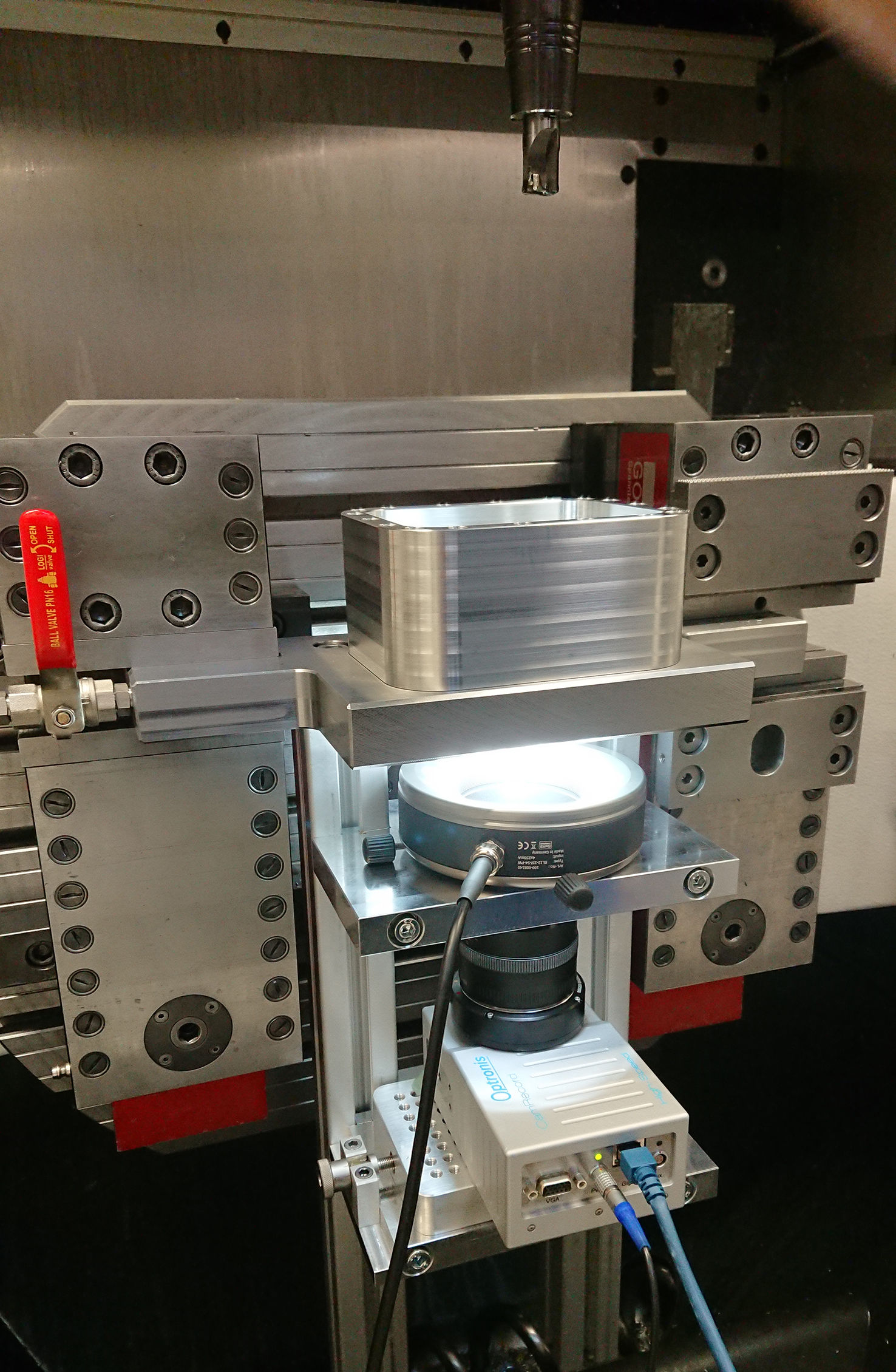

The idea of capturing the machining process, chip formation and the behavior of the metalworking fluid more precisely than ever before through photos and videos came about as part of a joint project with the renowned ETH Zurich. The research and development team at Swiss metalworking fluids experts, Blaser Swisslube, set about the planning and implementation. The use of a high-speed camera with a macro lens, which is placed behind a sight glass to keep the metalworking fluid at a distance, should make uniquely sharp, precise recordings possible. A ring light was used to provide the necessary light intensity, as well as a carbide cutter with a helix angle of 0° that was specially ground for this particular test.

The results are fascinating: The high-speed recordings showed for the first time that the mechanism of action of oil-free, water-soluble metalworking fluid, Synergy 735—namely its improved lubricating effect at higher temperatures - also occurs during machining and is fast enough to optimize milling processes. Synergy 735 thus changes its properties and adapts to the machining process like a chameleon.