5 Takeaways from the AGMA EV Town Hall

AGMA hosted an EV Town Hall last month during their Motion + Power Technology Expo (MPT Expo). This event was planned to explicitly ask the question, “Is industry ready to roll up its sleeves and start the process of sharing common outcomes that will serve as the building blocks for standards for electric vehicle technology?” Spoiler Alert: The answer was a resounding, yes. And the discussion uncovered some key issues, and perhaps a surprise or two, that will help AGMA leverage its 107 years of experience in this space to start to frame future discussions for electric vehicle standards development.

The morning started as it should with leaders of industry talking from the podium. Michael Cinquemani, CEO of Master Power Transmission, and current Chairman of the AGMA Board of Directors was sandwiched between AGMA staff leaders in emerging tech and technical standards development. Michael was the right bridge between the work of these two groups and the perfect person to ask the question: Are we ready? “As all of us in the room understand, electric vehicle technology is an exponentially growing sector with many opportunities,” he said. “As Chair of the AGMA Electric Vehicle Technology Committee, I have watched this industry develop over the last five years from the electric compact cars and the Tesla roadsters being the only vehicles to a sea change with all the major automobile manufacturers. We see a multitude of new players around the world building fully electric and hybrid-electric vehicles.” He went on to say, “I believe that we are at the inflection point where standards discussions need to start.”

AGMA had provided in advance a list of current standards that would apply to this sector—and could be a reference through the town hall discussions. These standards were organized around the topics of design, rating, and load calculation; metallurgy and materials; accuracy, tolerancing, and inspection; manufacturing and inspection; and wear and failure. A link to download the document is available at the end of this piece. More than 100 in attendance used this as a springboard for their robust conversation.

Here are some quick takeaways:

1. Industry is ready to talk standards for gearing in Electric Vehicles.

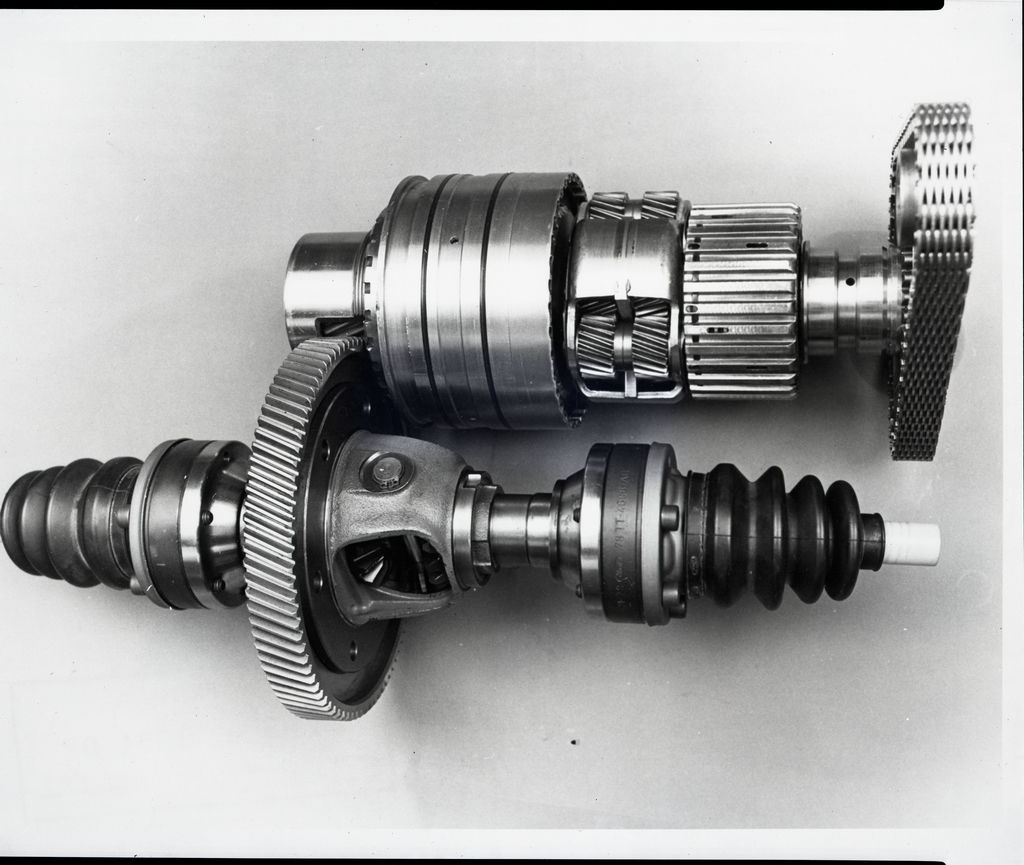

While the four following points are important, let’s not bury the lead on this one. AGMA’s biggest takeaway from the event is that industry is ready to talk standards. The process for standards development must, of course, begin with industry producing similar technology across a sector or multiple sectors. The AGMA emerging technology Electric Vehicle Committee has been monitoring this space for the last five years. The development of similar drivetrain technologies utilized on multiple vehicles by multiple companies and the build-out of the needed supply chains and/or internal tooling of manufacturing lines are key indicators a technology has hit mainstream and standards discussions may be beneficial.

Gear engineers showed up at this event armed with concrete examples of where they see gaps in the current standards and where they would like help with their current designs. Multiple examples of these are mentioned further down in this article.