Chiron Applies AM Coating Solution to Brake Disks

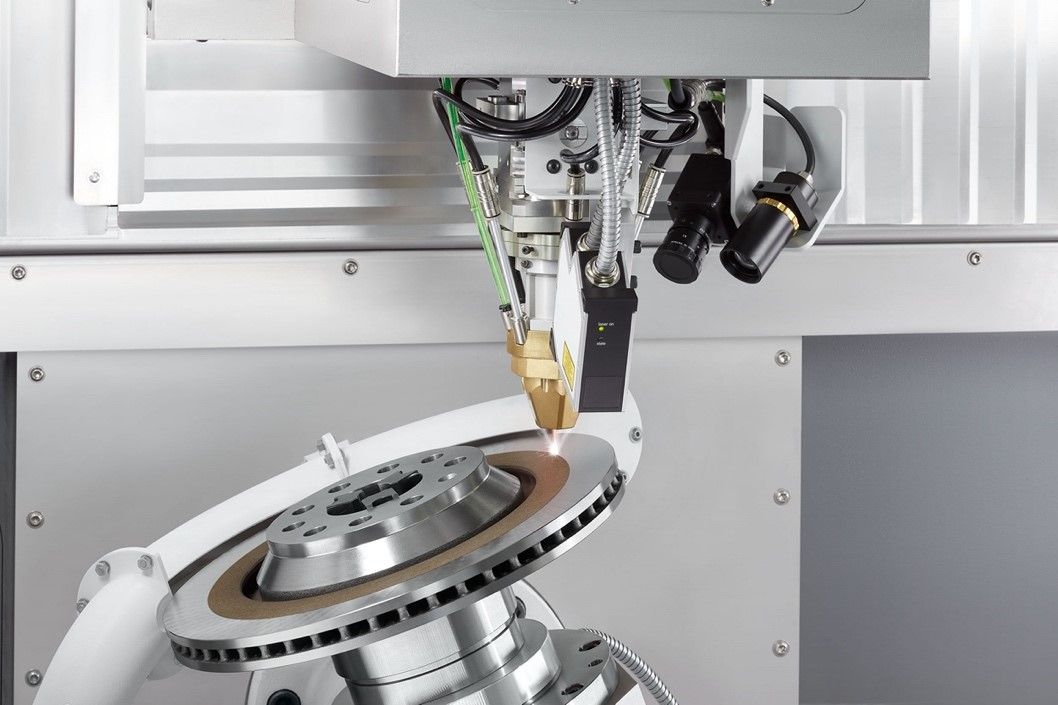

How can the protective layer be applied to the brake disk more quickly and more effectively? And how can it be made to stay on for longer? “The solution is intelligent coatings, as can be applied to brake disks using our AM coating system” says Dr. Géza Koscsák - the head of additive mat the Chiron Group. He has played a prominent role in developing the new system and reaching the decision to opt for the high-speed deposition welding process in his previous job as head of advanced development.

Innovative and productive process

Compared with the conventional LMD process, powder particles travel a longer distance before they are applied during high-speed laser material deposition. This means that they absorb more energy and melt in the laser beam, which enables a significantly faster coating speed. This process also has a clear advantage in comparison to thermal coating using high-velocity oxygen fuel spraying.

AM coating's quicker speed and shorter process are two advantages with respect to the future Euro 7 standard, believes Dr. Koscsák. “When the standard comes – and it certainly will come – a production volume of 10 million brake disks annually will need to be managed, for the European vehicle brands alone. With a cycle time for conventional brake disks of around 30 seconds per disk, it's clear that the coating process needs to keep up” he adds.

In line with market requirements: AM Coating available in two versions