For now, all 3-D printed parts have

by necessity been designed by Made In

Space engineers. But that will change

soon — especially with the arrival of

commercial-type 3-D printers, as mentioned

here by Kohlenberg.

“Our in-house engineers have

designed everything from the printer

itself to the parts that the printer has

printed. This is mostly due to the fact

that we are still wrapping up the very

first technology demonstration and are

just now finding customers. As soon as

we launch the commercially available

printer later this year, we expect the lion

share of the designs to primarily come

from our customers while our engineers

will provide design support as it relates

to printing on our printers in the zerogravity

environment.”

Said Jason Crusan, director of NASA’s

Advanced Exploration Systems Division,

“Additive manufacturing with 3-D printers

will allow space crews to be less reliant

on supply missions from Earth and

lead to sustainable, self-reliant exploration

missions where resupply is difficult and

costly.” And the technology will become

even more important for manned missions

to deep-space destinations such as

Mars, according to NASA officials.

What’s more, 3-D parts printing will

have a much-needed, salutary effect

on NASA’s deep-space budget. Doing

more with less is definitely an advantage

— whether on the ISS or factory

floor.

“We really want to see these things

(3-D printers) become the building

blocks for the future of exploration,”

Made in Space lead engineer Mike

Snyder told Space.com. “They really can

lead into sustainability in space, and

actually make these missions that cost a

lot of money be reduced just because you

don’t have to launch as much mass.”

Adds Kemmer, “It starts with tools and

spare parts, things like that, and eventually

leads to habitats, structures and

really everything that you need to live

off-world.”

‘Live off-world’ — the man says it as if

it were already a reality — perhaps a sign

that for NASA as well as space age entrepreneurs

like Elon Musk — populating

Mars is no longer a question of if — but

when.

Not wishing to be left behind, the

European Space Agency (ESA) plans

to launch its own 3-D printer to the

International Space Station in the first

half of this year. In fact the agency also

recently teamed with industrial partners

to investigate using 3-D printing technology

to build a moon base using lunar

materials.

“3-D printing offers a potential

means of facilitating lunar settlement

with reduced logistics from Earth,” Scott

Hovland, of ESA’s human spaceflight

team, said in a statement last year. “The

new possibilities this work opens up

can then be considered by international

space agencies as part of the current

development of a common exploration

strategy.”

The NASA site explains the 3-D

printer’s presence on the space station

as being part of the 3-D Print

Project — a collaboration between

NASA and Made In Space. The unit

sent up last September aboard SpaceX’s

unmanned Dragon cargo capsule was

then on Nov. 17 installed in the orbiting

lab’s Microgravity Science Glovebox

by Expedition 42 commander Barry

Wilmore.

Taking things one step beyond, Made

In Space plans to launch another printer

to the space station, on a production

rather than a demonstration mission.

This printer will be used for the aforementioned

“recycler” project.

The second phase of the project will

focus on actual use of production/

replacement parts printed on the ISS,

according to 3-D print program manager

Niki Werkheiser, of NASA’s Marshall

Space Flight Center in Huntsville,

Alabama. As with her counterparts,

Werkheiser is thrilled with developments

thus far. After all, not everyone gets a

chance to be in on the ground floor of

a new technology that by all indications

definitely has legs.

“I think we’re making history by, for

the first time ever, being able to make

what we need, when we need it, in

space,” Werkheiser said on NASA TV

when the printer was installed. “Even

though it may sound a little like science

fiction, we’re actually able to email our

hardware to space instead of launching

it.” (Sources: NASA.GOV, NASATV.GOV

and SPACE.COM.)

NASA Embraces 3-D Printing

The ability to “print” everything

from human body parts to

works of art to rocket engines

is rapidly changing the world

of manufacturing.

NASA has been

involved in additive manufacturing, or

3-D printing, since the 1990s when it

was still an emerging technology. In

the early days, it was often called rapid

prototyping. Designers used printers to

make plastic models to explore possibilities

before they built a more costly part

with metal. Printers were too small and

could not make the quality parts needed

for NASA flight hardware.

Now, making a part with additive

manufacturing is not only more costeffective,

but also the printers can make

larger parts of higher quality and with

different materials — or even combinations

of materials. NASA is exploring

the use of many types of additive manufacturing

that can benefit every phase

of NASA missions — from launch to

science payload development to robotic

exploration to deep space missions.

Across the agency, engineers and designers

are trying out many types of 3-D

printers that work with a variety of plastics

and metals, including titanium, aluminum,

Inconel and other nickel alloys

widely used in aerospace manufacturing.

Often a computer sends a design to

a 3-D printer, and the machine makes

the part in fewer pieces than would be

required with traditional welding and

assembly. Some additive manufacturing

processes melt plastic or metal wire to

form a part. For example, electron beams

can be used to melt metal wire. Others

use lasers to melt metal powders layer by

layer until a part is formed.

To put this new type of manufacturing

to the test, NASA is printing and testing

rocket parts, telescope optics, and even

parts of experiment equipment. When it

makes sense, NASA plans to take advantage

of 3-D printing in almost every type

of mission from launch vehicles to robotic

landers to parts needed in a space habitat.

The International Space Station has

become a test bed for this new technology

to explore additive manufacturing

in space — the first step toward in-situ

resource utilization on orbit or at exploration

destinations. Indeed, the technology

could prove critical to space explorers

on future long- and deep-space missions.

(NASA.GOV)

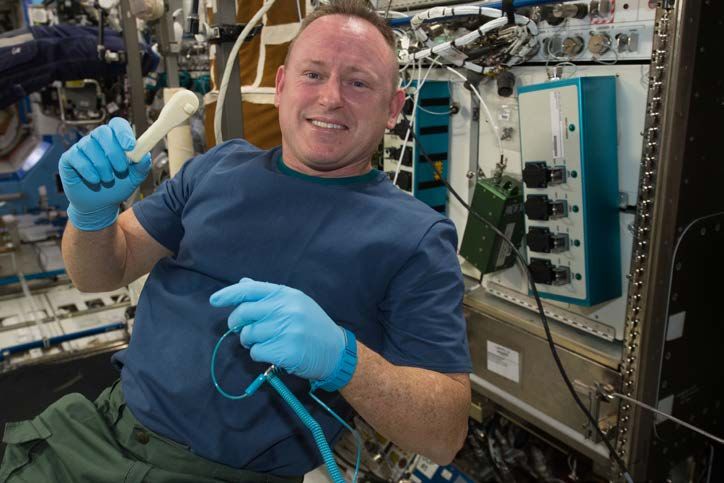

ISS commander Butch

Wilmore displays a working

socket wrench — with ratchet

action capability — that was

printed using digital plans

emailed to the station by NASA

Mission Control (Photo courtesy

of NASA).

ISS commander Butch

Wilmore displays a working

socket wrench — with ratchet

action capability — that was

printed using digital plans

emailed to the station by NASA

Mission Control (Photo courtesy

of NASA).

Made In Space CEO Aaron Kemmer stares through the

windows of the Microgravity Science Glovebox with the

Zero-G 3D Printer enclosed (Photo: Made In Space).

Made In Space CEO Aaron Kemmer stares through the

windows of the Microgravity Science Glovebox with the

Zero-G 3D Printer enclosed (Photo: Made In Space). Made In Space’s NASA-contracted, first 3D printer, was

sent to the ISS on September 21st, 2014. The ivory

objects on top are duplicates of what will soon be

some of the first objects ever printed off-Earth. In the

background is the Microgravity Science Glovebox that

will contain the printer during the 3D Printing in Zero-

Gravity Experimentation (Photo: NASA/Emmett Given).

Made In Space’s NASA-contracted, first 3D printer, was

sent to the ISS on September 21st, 2014. The ivory

objects on top are duplicates of what will soon be

some of the first objects ever printed off-Earth. In the

background is the Microgravity Science Glovebox that

will contain the printer during the 3D Printing in Zero-

Gravity Experimentation (Photo: NASA/Emmett Given).