Synchronization property. When the oscillator is subjected

to an external periodic signal p (Ωt), the mathematical model of

Matsuoka’s neural oscillator becomes:

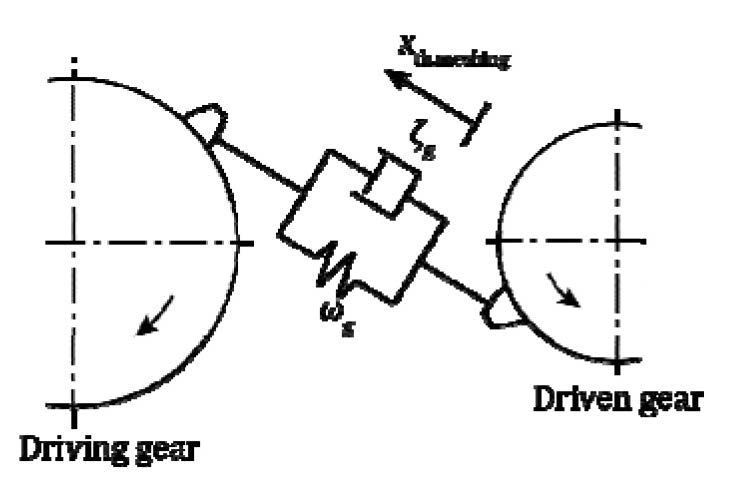

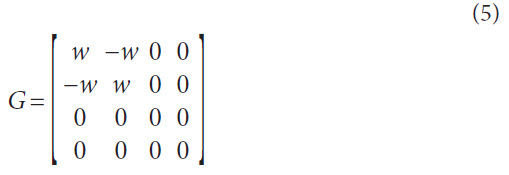

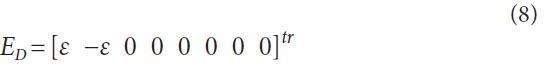

Where, ED is an input matrix as follows:

Here, ε is an input gain, and p (Ωt) is a normalized sinusoidal

signal whose frequency is Ω. If the frequency Ω is partially close

to the Eigen frequency ωD of the neural oscillator, the oscillator

is thus synchronized with the external sinusoidal wave.

This synchronization phenomenon can be seen when the

detuning Ω-ωD between the oscillator’s frequency ωD and the

external periodic force’s frequency Ω is a finite value. According

to an analysis by the phase reduction method (Refs. 9–10), the

synchronization region ε Γmin < Ω-ωD < ε Γmax is decided. Here,

Γmin, max is the phase coupling function of the oscillator.

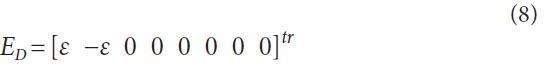

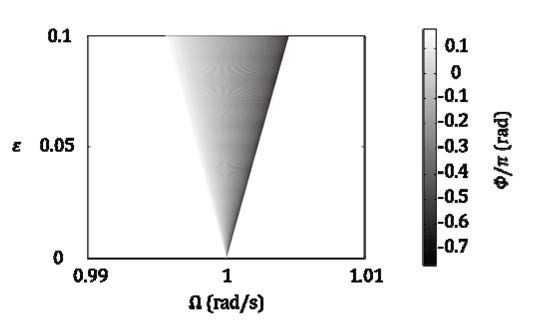

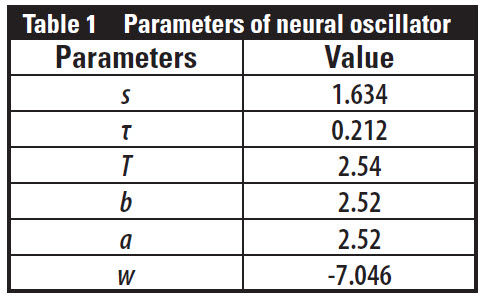

Figure 1 shows a synchronization region of the neural oscillator

(Table 1).

Figure 1 Synchronizing region of neural oscillator.

The colored area is the region also known as

Arnold’s tongue. In this figure the horizontal axis is the frequency

Ω of input, and the vertical axis is the amplitude ε of

input. It is clear that the synchronization region has spread

from the oscillator’s frequency ωD = 1 — when the amplitude of

the external forcing is increased. The synchronization region

depends on the amplitude

of the forcing.

Increased the coefficient

for the external

forcing in the neural

oscillator, the region

can be freely adjusted.

The color in this figure

shows the phase difference (phase locking points) between input/output of the

neural oscillator.

While the neural oscillator has a sensitive reaction to the sinusoidal

input within the synchronization region, it does not have

the same sensitivity to the input outside of the region. Thus the

neural oscillator can be used as an adaptive, single-frequency

generator, and as an adaptive notch filter to cancel the unnecessary

frequency component in the vibration response of the

meshing gears.

Gear Meshing

In this section a model of gear meshing vibration in a circumferential

direction — used for verification of a proposed noise-can-cellation system by simulation — is explained. Later, amplitude

and frequency modulation caused by the eccentricities of gears

are considered.

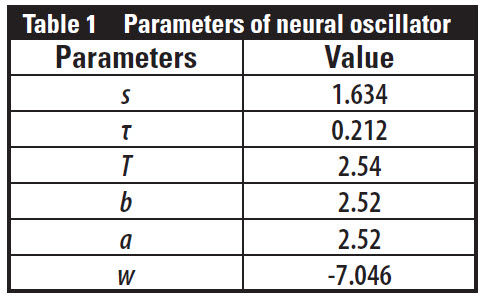

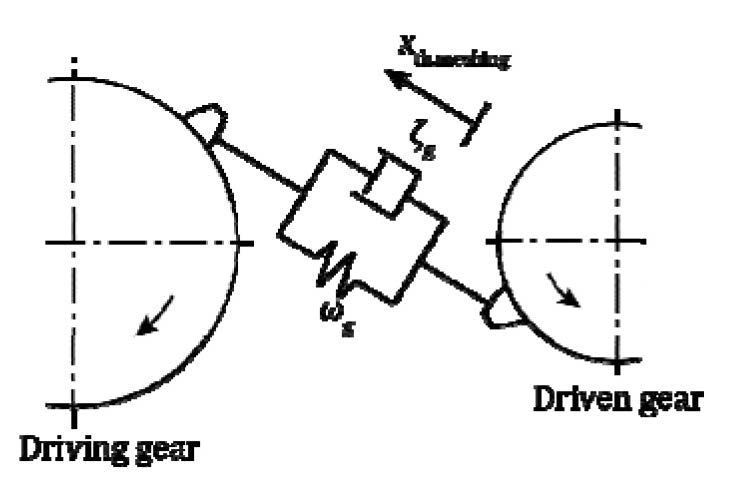

Dynamic loads on gear teeth. A simple vibration model in

meshing gear pairs is used for simulation (Fig. 2).

Figure 2 Vibration model in meshing gear pairs.

Each gear has

a mass and is connected to the other by a spring and damper

(Ref. 11). This vibration model — in a circumferential direction

— is considered to be a single-degree-of-freedom vibration

system as follows:

Where, xth, meshing (t) is spring deflection of the vibration system;

ωg is the natural frequency of the system; ζg is the damping

ratio depending on the gear material; e(t) is tooth profile

error — and this error is the input displacement to the system.

Here it was assumed that the driving torque variation of the

rotating shaft was small and the effect of the shaft stiffness on

the line of action of force was small as well.

A meshing condition of a spur gear pair varies with time t.

Considering the meshing period Tz, periodic change of total

tooth stiffness during 0 ≤ t < z2Tz is expressed as follows:

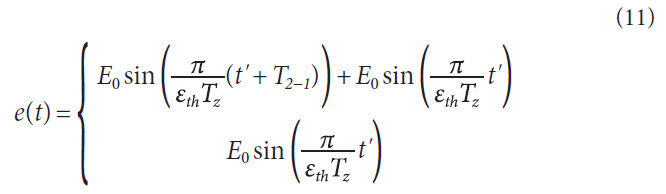

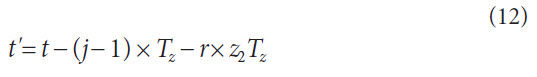

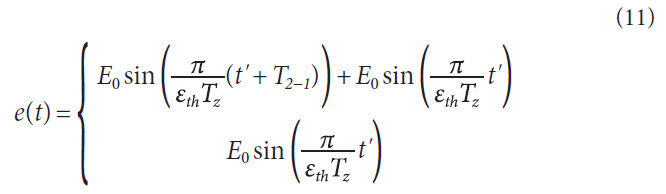

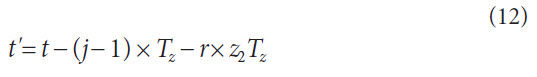

In this study, the tooth profile error e(t) is also expressed as

follows:

Where, εth is contact ratio of the spur gear pair, and is

obtained as follows:

ωg,j is the time-varying, natural frequency of the meshing gear

system during meshing period that is derived from Ishikawa’s

tooth stiffness variation and the equivalent inertia mass on the

pitch circle (Ref. 12). In addition, subscript j indicates the number

of meshing tooth pairs, obtained as follows:

By using contact ratio εth,the transition time T2-1 from two

pair teeth in mesh to a single pair is obtained as follows:

And Tsmooth is a time constant of a first-order lag system to

vary the natural frequency smoothly, here as Tsmooth = σsmoothTz.

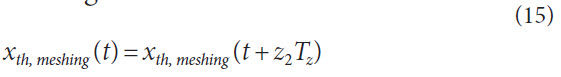

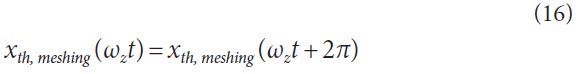

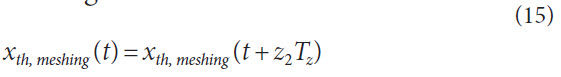

Xth,meshing changes periodically, the timeframe dependent upon

the rotation of the driven gear as follows:

Amplitude and frequency modulation by an eccentric error

of a driven gear. Generally the vibration caused by the tooth-totooth

meshing of a rotating gear pair contains various frequency

components that are due not only to amplitude and frequency

modulation caused by eccentricity of gears, but also to the rolling-

elements noise of bearings, motor vibration and its harmonics,

and so on. The effects of these unnecessary components on

the measured vibration make detection of gear faults — such as

gear tooth cracks — difficult.

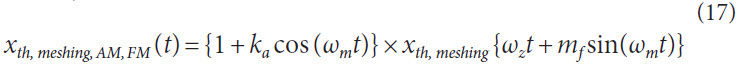

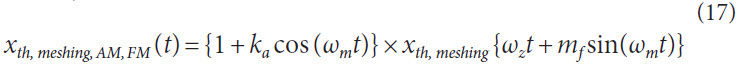

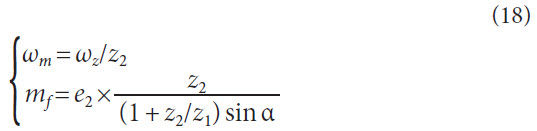

In this subsection a model that includes the amplitude and frequency

modulation caused by an eccentric error of a driven gear

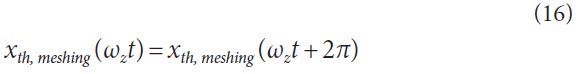

is considered. Considering the meshing frequency ωz = 2π/Tz, the

periodic variable is expressed as follows:

The effect of amplitude and frequency modulation on the

variable can be expressed as follows

(Ref. 13):

Where,

and e2 is the ratio of the radius of pitch circle of the driven gear

to the eccentric error of the gear; ka is the amplitude modulation

factor; mf is the frequency modulation factor; α is the pressure

angle; and z the tooth number.

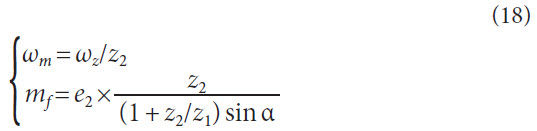

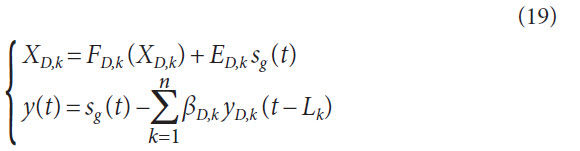

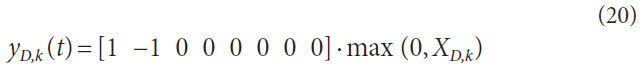

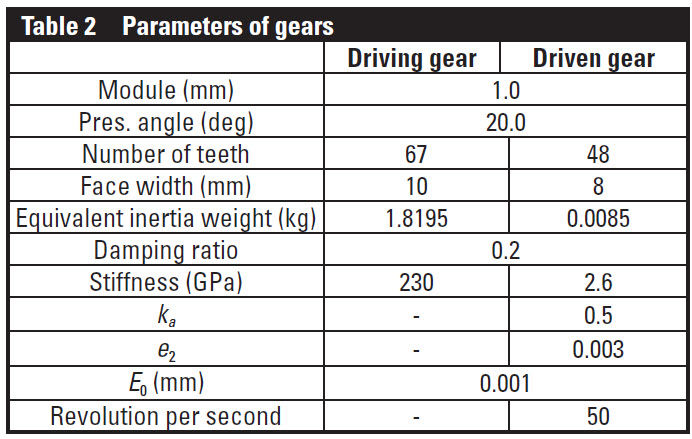

Numerical simulation of meshing gear vibration. According

to the abovementioned gear model, numerical simulations of meshing gears are carried out using the Runge-Kutta Fourth

Order Method (Table 2). The step time of the simulations is

10-6 s, and σsmooth = 10-2.

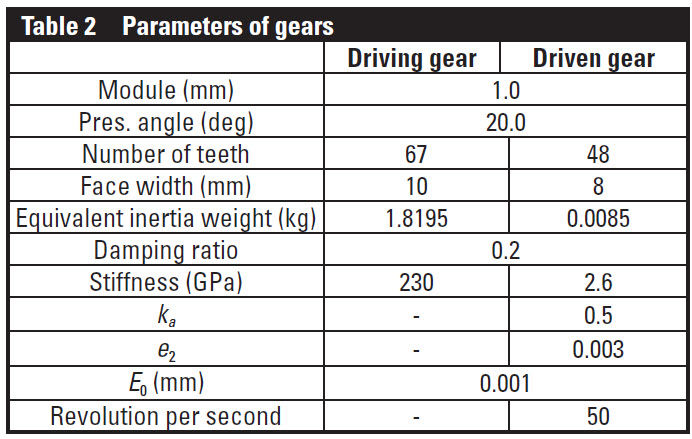

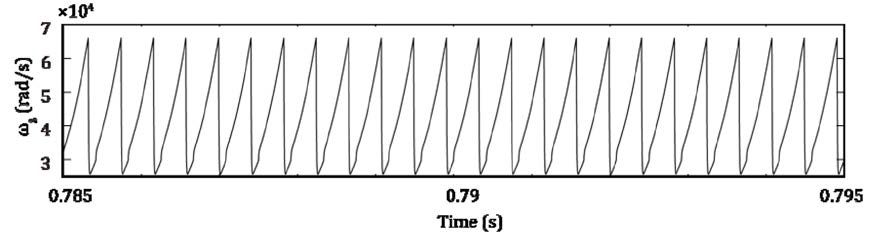

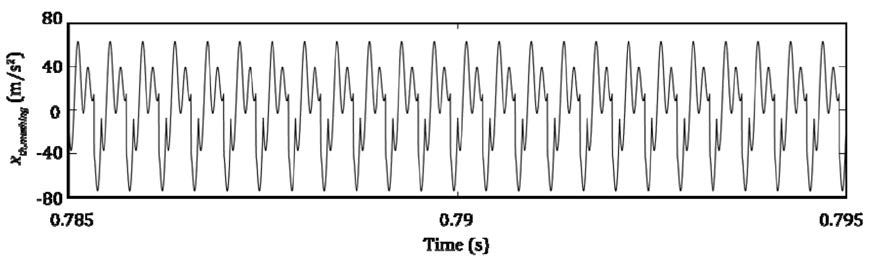

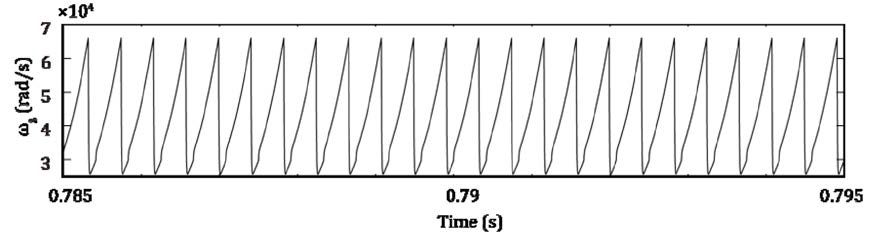

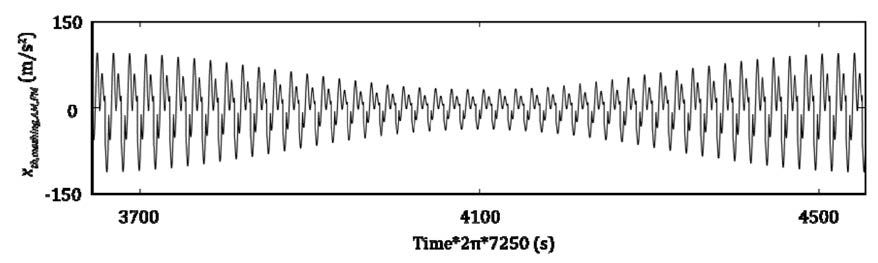

The results of numerical simulations are shown in following

figures. Figure 3 shows the change of the natural frequency of

the system.

Figure 3 Natural frequency of gear meshing.

In this figure the natural frequency changed periodically

because the meshing condition of a spur gear pair varied

with time t. In considering the change of the natural frequency,

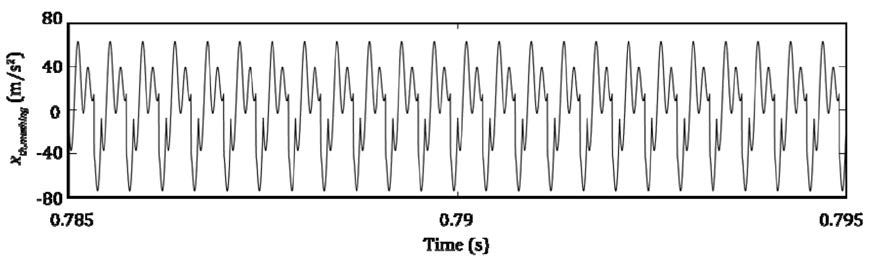

the acceleration response of the system is obtained (Fig. 4).

Figure 4 Acceleration response of gear meshing.

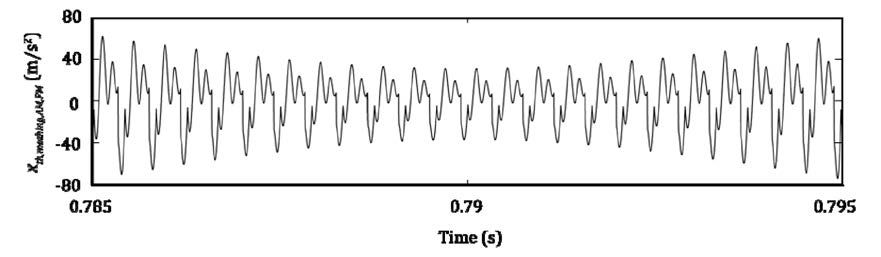

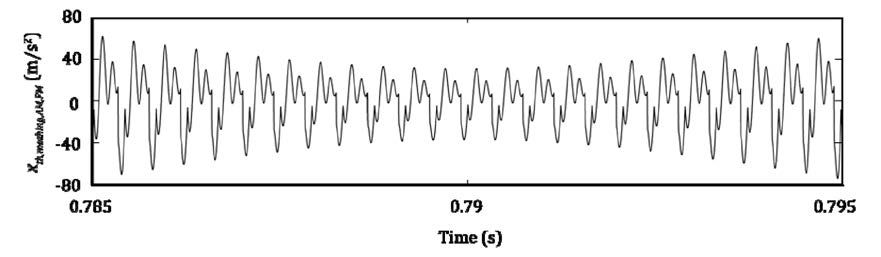

As for the eccentric error of the gear, the acceleration response

of the system is subject to influence by both amplitude and

frequency modulation (Fig. 5).

Figure 5 Acceleration response of gear meshing with AM and FM.

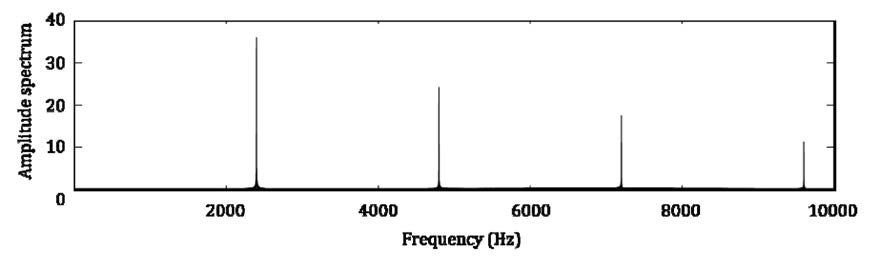

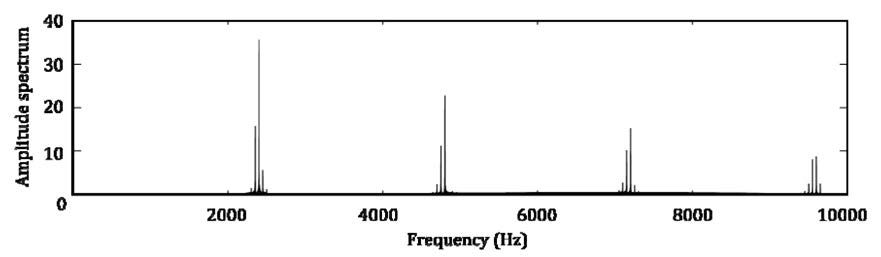

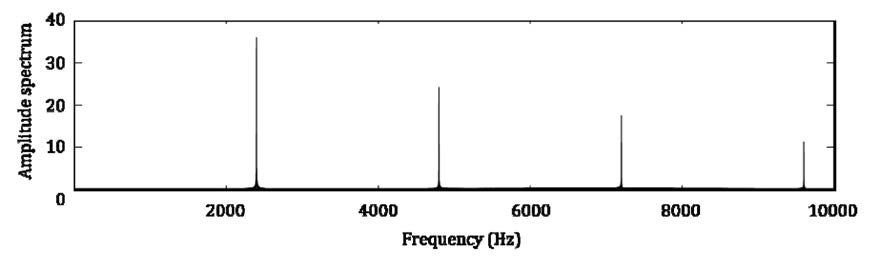

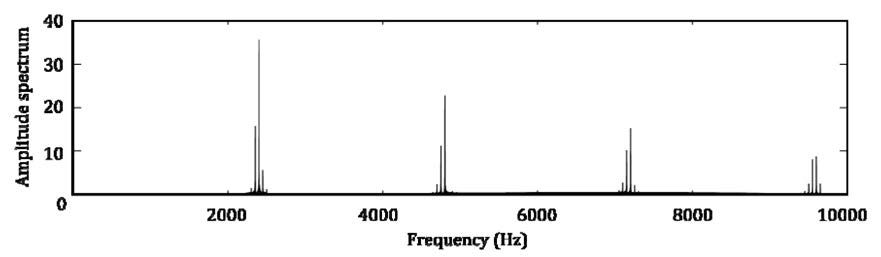

Figures 6 and 7 show the frequency

responses, with and without modulation, respectively.

As a result of the modulation some sideband peaks can be seen

(Fig. 7) when compared with Figure 6.

Figure 6 FFT of gear meshing.

Figure 7 FFT of gear meshing with AM and FM.

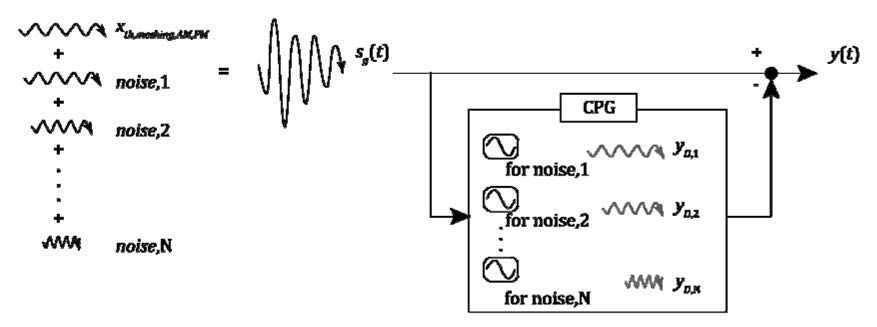

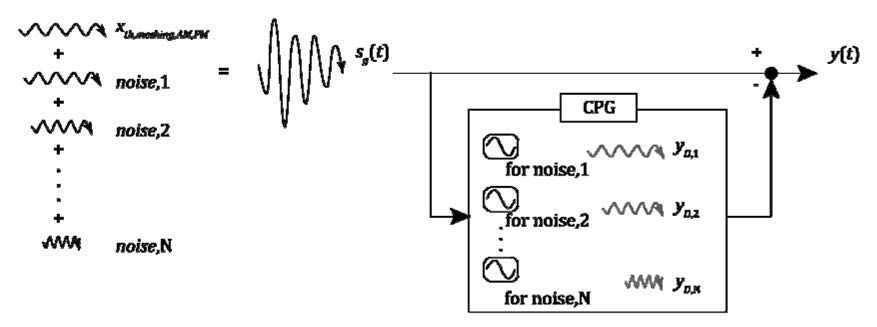

Noise-Canceling System

Here a noise cancellation system using neural oscillators to filter

out the background noise of vibration in meshing plastic

gear pairs for detection of failure signs of the gears is explained.

The acceleration response, which is measured on the top of the

housing at the gear shaft bearing, includes not only the DC;

shaft frequency; its harmonics; fundamental meshing frequency;

some mesh harmonics; and its modulating sidebands; but

also rolling-elements noise of bearings, motor vibration and its

harmonics, and so on. Detecting gear faults is much more difficult

in the complex response; therefore these unnecessary frequency

components should be eliminated from the response.

However, the frequency of the unnecessary components

attracts a great amount of influence from the driving torque variation.

The proposed new filter system using the neural oscillators

can autonomously follow the frequency change of the unnecessary

component due to the synchronization property (Fig. 8).

Figure 8 Concept of feed-forward noise cancelling system using neural oscillators.

The proposed system has a measured signal and consists of

some neural oscillators. The number of oscillators is the same as

the number of unnecessary components. Each neural oscillator

is designed to tune the natural frequency in to a particular frequency

of the component. Moreover, the output of the oscillators

is set to be out-of-phase with the input by 180° and is combined

with the original, measured response to reduce the amplitude of

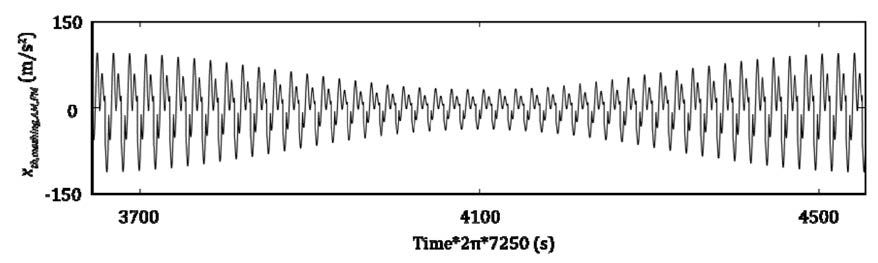

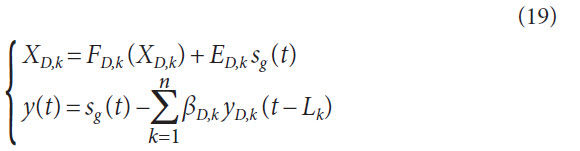

the unnecessary components. The system is expressed as follows:

where βDk is an arbitrary output gain of the oscillator, and Lk

is a delay time of the system. Moreover, the output of the each

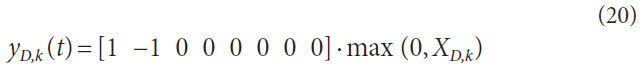

oscillator is obtained as follows:

Results of Numerical Simulation

to the simulated response to confirm validity of the system. In

this simulation the analyzed signal consists of the abovementioned

acceleration response and an unnecessary component

20sin (2π *7,250*t), which is the same frequency of the modulated,

third-order, high-frequency content.

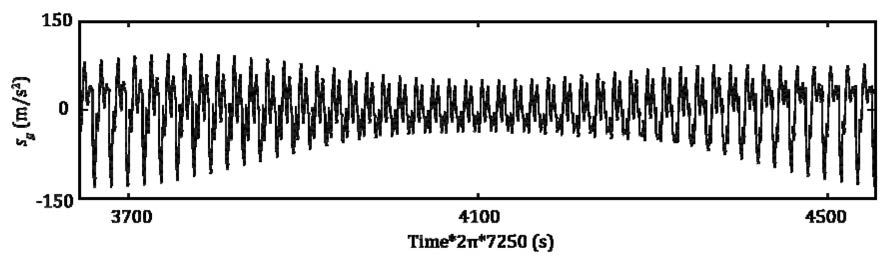

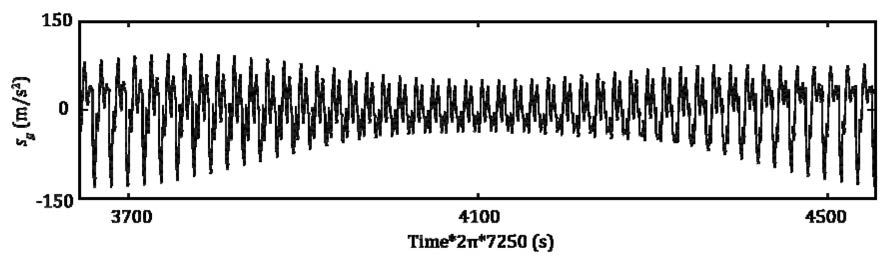

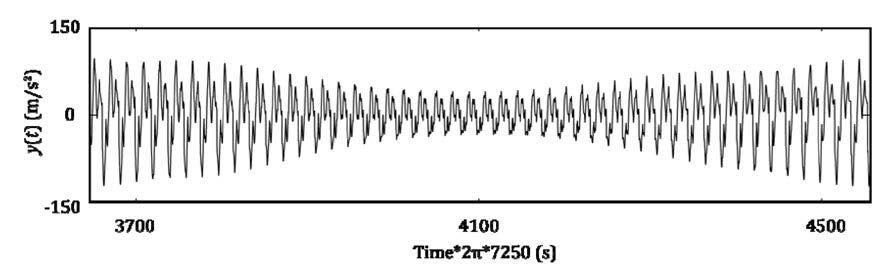

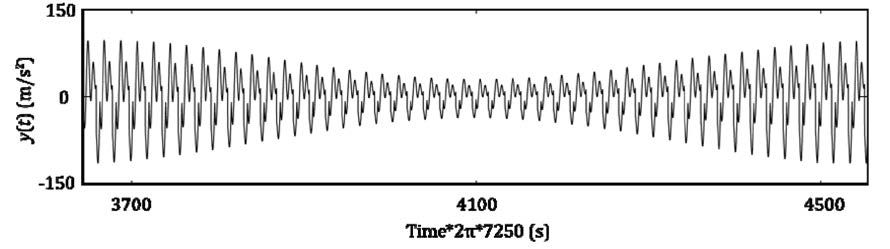

Figure 9 shows the abovementioned acceleration response

without the noise, and Figure 10 the signal with the noise; in

both figures the time is multiplied by 2π *7,250.

Figure 9 Acceleration response of gear meshing with AM and FM.

Figure 10 Acceleration response of gear meshing with AM, FM and external noise.

As can be seen, the modulated noise complicates the acceleration

response of gear meshing, even if the noise consists of the

single component.

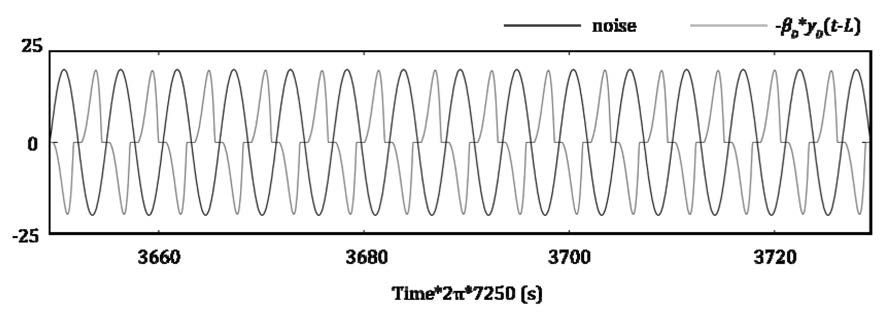

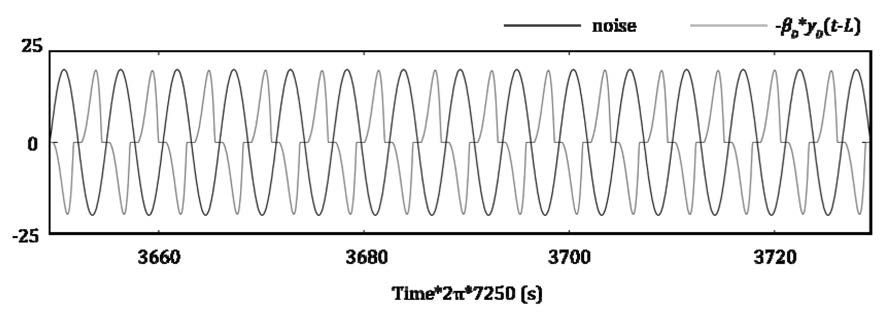

Next are shown the results of the noise cancellation system.

The frequency of the neural oscillator was set to the frequency

of the unnecessary component (Table 1). Figure 11 shows the

output of the designed neural oscillator and the noise component;

as can be seen, the output of the neural oscillator has the

same frequency of the noise, and is out-of-phase by 180°.

Figure 11 Output of the designed neural oscillator and noise component.

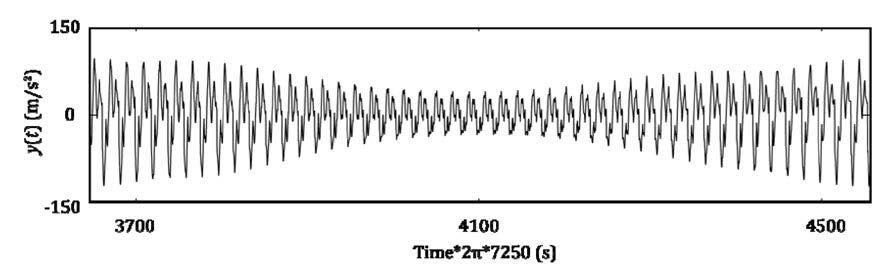

Figure 12 shows the result of noise cancellation using the

original output of the neural oscillator. In this simulation, ε

=0.0002 βD = 20/7, L = 5.5s. In the figure the unnecessary component

was reduced by the effect of the proposed filter, but discontinuous

changes can be seen due to the non-linear property

of the neural oscillator. This non-linear oscillator — having a

sinusoidal input — has a limit cycle. If “phase” is pre-defined on

the limit cycle, the phase and amplitude of the neural oscillator

as a sinusoidal wave can be constructed by the defined “phase.”

To realize this construction, a phase map was used (Ref. 14).

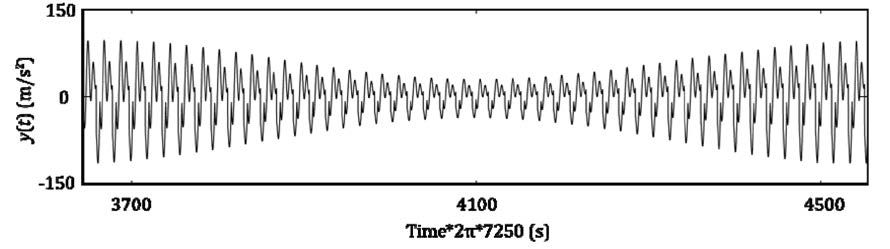

Figure 13 shows the result of noise cancellation using the constructed

sinusoidal wave by the neural oscillator and the phase

map. As can be seen, the original vibration of gear meshing is

reconstructed.

Figure 12 Result of noise cancellation using output of the neural oscillator.

Figure 13 Result of noise cancellation using the constructed sinusoidal wave by the oscillator and phase map.

Conclusions

This paper proposed a new method using neural oscillators to

filter out the background noise of vibration in meshing plastic

gear pairs for detection of gear failure signs. It was shown how

to eliminate unnecessary frequency components, with a feedforward

control system providing a neural oscillator’s synchronization

property. Each neural oscillator is designed to tune the

natural frequency to a particular frequency of unnecessary components.

The designed neural oscillators can follow the change

in the driving torque variation autonomously, using their synchronization

property. Moreover, the output of the oscillators

is set to have a difference in the phase of 180 degrees from the

input, and is included in the original measured response to

reduce the amplitude of unnecessary components. The proposed

noise cancellation method applied to the simulated

response, and it was concluded that the proposed system could

sufficiently eliminate unnecessary vibration content.

In future works we will design the suitable input and output

gain for these oscillators, which could be determined through

trial and error, and will confirm the oscillators’ tracking properties.

Furthermore, we will validate the multiple-elimination of

unnecessary components and will apply the advanced system to

the acceleration response measured by operating tests of gears,

and assessing the efficacy of the system.

Acknowledgements. The authors gratefully acknowledge the

support of the department of mechanical and system engineering

at the Kyoto Institute of Technology and Mitutoyo Association for

Science and Technology, R1301.

Hidetaka Hiramatsu is a student in Mechanical

and System Engineering at Kyoto Institute of

Technology, received his bachelor degree in

mechanical engineering from Kyoto Institute of

Technology in 2014. His research interest is gear

failure detection by vibration analysis.

A PhD candidate student in design engineering

at Kyoto Institute of Technology (KIT), Junichi

Hongu began research in 2010 on application

of neural oscillators for vibration control at

KIT’s Precision Manufacturing Laboratory. He

subsequently in 2013 became a member of the

project team researching gear failure by vibration

analysis.

Daisuke Iba, associate professor of mechanical

and system engineering at Kyoto Institute

of Technology, received his Ph.D. degree in

mechanical engineering from the institute in 2005,

and his bachelor and master degrees in mechanical

engineering from Hosei University in 1995 and 1997,

respectively. Iba’s research interests are structural

response control and health monitoring, gear

system condition monitoring and smart gear sensor

development.

Arata Masuda, professor of mechanical

engineering at Kyoto Institute of Technology,

received his Ph.D degree in mechanical engineering

there in 1999, and his BS from Kyoto University in

1990. His research has been in the area of smart

structural systems and structural intelligence,

including structural health monitoring, machine

condition monitoring, vibration energy harvesting,

vibration control and human motion monitoring and assistance.

Prof. Dr.Eng. Ichiro Moriwaki is a professor

of mechanical and system engineering at Kyoto

Institute of Technology and the director of the KIT

Liaison Center. He received a doctorate degree of

engineering from Kyoto University in 1989. He was

the chairman of gearing committee in JSME in 2011-

2013, and still a member of the committee. Moriwaki

is also chairman of ISO / JIS standards committee in

JGMA, a Japanese delegate for ISO TC 60.

Morimasa Nakamura has a Ph. D in engineering

and is an assistant professor at the Kyoto Institute of

Techonology. His primary research field is tribology,

surface treatment technology and gearing.

Prof. Akira Sone earned his bachelor’s, master’s

and Ph.D. degrees in mechanical engineering at

Tokyo Metropolitan University in 1981, 1983 and 1987,

respectively, working there as a research associate

from 1987 to 1989. He has been on the faculty of the

mechanical and system engineering department

at Kyoto Institute of Technology since 1989. He has

been an associate professor and a professor there

since 1991 and 1999, respectively. Sone’s research

focus is seismic engineering and structural response control.

References:

- Iba, D., S. Ohmori, J. Hongu, M. Nakamura and I. Moriwaki. “Failure

Detection of Plastic Gears Based on a Comparison of Fourier Coefficients

of a Gear Mesh Vibration Model by Rectangle Pulse Train and Frequency

Analysis of Acceleration Response,” 2013 Trans. of the Japan Society of

Mechanical Engineers Series C. 79-808, 5138-5148, http://dx.doi.org/10.1299/

kikaic.79.5138.

- Shik, M. L. and G.N. Orlovsky. Neurophysiology of Locomotor Automatism,

Physiol. Rev., 1976, 56, 465-501.

- Matsuoka, K. “Sustained Oscillations Generated by Mutually Inhibiting

Neurons with Adaptation,” Biological Cybernetics, 1985, 52, 367-376.

- Matsuoka, K. “Mechanisms of Frequency and Pattern Control in Neural

Rhythm Generators,” Biological Cybernetics, 1987, 56, 345-353.

- Taga, G., Y. Yamaguchi and H. Shimizu. “Self-Organized Control of Bi-Pedal

Locomotion by Neural Oscillators in Unpredictable Environment,” Biological

Cybernetics. 1991, 65, 147-159.

- Fukuoka, Y. and H. Kimura. “Adaptive Dynamic Walking of a Quadruped

Robot on Irregular Terrain based on Biological Concepts,” 2003,

International Journal of Robotics Research, 22-3-4, 187-202.

- Iba, D. and J. Hongu. “Structural Vibration Control by Tuned Mass Damper

Using Central Pattern Generator,” 2011 Proc. SPIE 7981, Sensors and Smart

Structures Technologies for Civil, Mechanical, and Aerospace Systems, 79814Q.

DOI:10.1117/12.880406.

- Hongu, J. and D. Iba. “Mutual Synchronization Between Structure and

Central Pattern Generator,” 2012 Proc. SPIE 8345, Sensors and Smart

Structures Technologies for Civil, Mechanical, and Aerospace Systems, 83451E.

DOI:10.1117/12.915045.

- Kuramoto, Y. Chemical Oscillations, Waves, and Turbulence, 2003, Dover

Press.

- Pikovsky, A., M. Rosenblum and J. Kurths. Synchronization: A Universal

Concept in Non-Linear Sciences, 2001, Cambridge University Press.

- Umezawa, K., T. Sato and S. Ishikawa. “Simulation on Rotational Vibration of

Spur Gears,” 1983 Transactions of the Japan Society of Mechanical Engineers,

Series C. 49-441, 794-802 Series C.

- Ishikawa, J. “On the Deflection of Gear Teeth,” 1951 Transactions of the Japan

Society of Mechanical Engineers, 17-59, 103-106. http://dx.doi.org/10.1299/

kikai1938.17.59_103.

- Nishida, N. and Y. Maruki. “The Characteristic of Noise Spectrum of

Gears with Eccentric Errors,” 1981 Transaction of Japan Society of Precision

Engineering, 51 (3), 547-552.

- Hongu, J., D. Iba, M. Nakamura and I. Moriwaki. “Vibration Control of

Structures by a Dynamic Absorber Using a Neural Oscillator (Specification

Method of Dynamic Absorber’s Stroke Width Using an Amplitude Map), The

56th Japan Joint Automatic Control Conference, 2013, CD-ROM, No.129.

Figure 1 Synchronizing region of neural oscillator.

Figure 1 Synchronizing region of neural oscillator.

Figure 2 Vibration model in meshing gear pairs.

Figure 2 Vibration model in meshing gear pairs.

Figure 3 Natural frequency of gear meshing.

Figure 3 Natural frequency of gear meshing. Figure 4 Acceleration response of gear meshing.

Figure 4 Acceleration response of gear meshing. Figure 5 Acceleration response of gear meshing with AM and FM.

Figure 5 Acceleration response of gear meshing with AM and FM. Figure 6 FFT of gear meshing.

Figure 6 FFT of gear meshing. Figure 7 FFT of gear meshing with AM and FM.

Figure 7 FFT of gear meshing with AM and FM. Figure 8 Concept of feed-forward noise cancelling system using neural oscillators.

Figure 8 Concept of feed-forward noise cancelling system using neural oscillators.

Figure 9 Acceleration response of gear meshing with AM and FM.

Figure 9 Acceleration response of gear meshing with AM and FM. Figure 10 Acceleration response of gear meshing with AM, FM and external noise.

Figure 10 Acceleration response of gear meshing with AM, FM and external noise. Figure 11 Output of the designed neural oscillator and noise component.

Figure 11 Output of the designed neural oscillator and noise component. Figure 12 Result of noise cancellation using output of the neural oscillator.

Figure 12 Result of noise cancellation using output of the neural oscillator. Figure 13 Result of noise cancellation using the constructed sinusoidal wave by the oscillator and phase map.

Figure 13 Result of noise cancellation using the constructed sinusoidal wave by the oscillator and phase map. Hidetaka Hiramatsu is a student in Mechanical

and System Engineering at Kyoto Institute of

Technology, received his bachelor degree in

mechanical engineering from Kyoto Institute of

Technology in 2014. His research interest is gear

failure detection by vibration analysis.

Hidetaka Hiramatsu is a student in Mechanical

and System Engineering at Kyoto Institute of

Technology, received his bachelor degree in

mechanical engineering from Kyoto Institute of

Technology in 2014. His research interest is gear

failure detection by vibration analysis. A PhD candidate student in design engineering

at Kyoto Institute of Technology (KIT), Junichi

Hongu began research in 2010 on application

of neural oscillators for vibration control at

KIT’s Precision Manufacturing Laboratory. He

subsequently in 2013 became a member of the

project team researching gear failure by vibration

analysis.

A PhD candidate student in design engineering

at Kyoto Institute of Technology (KIT), Junichi

Hongu began research in 2010 on application

of neural oscillators for vibration control at

KIT’s Precision Manufacturing Laboratory. He

subsequently in 2013 became a member of the

project team researching gear failure by vibration

analysis. Daisuke Iba, associate professor of mechanical

and system engineering at Kyoto Institute

of Technology, received his Ph.D. degree in

mechanical engineering from the institute in 2005,

and his bachelor and master degrees in mechanical

engineering from Hosei University in 1995 and 1997,

respectively. Iba’s research interests are structural

response control and health monitoring, gear

system condition monitoring and smart gear sensor

development.

Daisuke Iba, associate professor of mechanical

and system engineering at Kyoto Institute

of Technology, received his Ph.D. degree in

mechanical engineering from the institute in 2005,

and his bachelor and master degrees in mechanical

engineering from Hosei University in 1995 and 1997,

respectively. Iba’s research interests are structural

response control and health monitoring, gear

system condition monitoring and smart gear sensor

development. Arata Masuda, professor of mechanical

engineering at Kyoto Institute of Technology,

received his Ph.D degree in mechanical engineering

there in 1999, and his BS from Kyoto University in

1990. His research has been in the area of smart

structural systems and structural intelligence,

including structural health monitoring, machine

condition monitoring, vibration energy harvesting,

vibration control and human motion monitoring and assistance.

Arata Masuda, professor of mechanical

engineering at Kyoto Institute of Technology,

received his Ph.D degree in mechanical engineering

there in 1999, and his BS from Kyoto University in

1990. His research has been in the area of smart

structural systems and structural intelligence,

including structural health monitoring, machine

condition monitoring, vibration energy harvesting,

vibration control and human motion monitoring and assistance. Prof. Dr.Eng. Ichiro Moriwaki is a professor

of mechanical and system engineering at Kyoto

Institute of Technology and the director of the KIT

Liaison Center. He received a doctorate degree of

engineering from Kyoto University in 1989. He was

the chairman of gearing committee in JSME in 2011-

2013, and still a member of the committee. Moriwaki

is also chairman of ISO / JIS standards committee in

JGMA, a Japanese delegate for ISO TC 60.

Prof. Dr.Eng. Ichiro Moriwaki is a professor

of mechanical and system engineering at Kyoto

Institute of Technology and the director of the KIT

Liaison Center. He received a doctorate degree of

engineering from Kyoto University in 1989. He was

the chairman of gearing committee in JSME in 2011-

2013, and still a member of the committee. Moriwaki

is also chairman of ISO / JIS standards committee in

JGMA, a Japanese delegate for ISO TC 60. Morimasa Nakamura has a Ph. D in engineering

and is an assistant professor at the Kyoto Institute of

Techonology. His primary research field is tribology,

surface treatment technology and gearing.

Morimasa Nakamura has a Ph. D in engineering

and is an assistant professor at the Kyoto Institute of

Techonology. His primary research field is tribology,

surface treatment technology and gearing. Prof. Akira Sone earned his bachelor’s, master’s

and Ph.D. degrees in mechanical engineering at

Tokyo Metropolitan University in 1981, 1983 and 1987,

respectively, working there as a research associate

from 1987 to 1989. He has been on the faculty of the

mechanical and system engineering department

at Kyoto Institute of Technology since 1989. He has

been an associate professor and a professor there

since 1991 and 1999, respectively. Sone’s research

focus is seismic engineering and structural response control.

Prof. Akira Sone earned his bachelor’s, master’s

and Ph.D. degrees in mechanical engineering at

Tokyo Metropolitan University in 1981, 1983 and 1987,

respectively, working there as a research associate

from 1987 to 1989. He has been on the faculty of the

mechanical and system engineering department

at Kyoto Institute of Technology since 1989. He has

been an associate professor and a professor there

since 1991 and 1999, respectively. Sone’s research

focus is seismic engineering and structural response control.