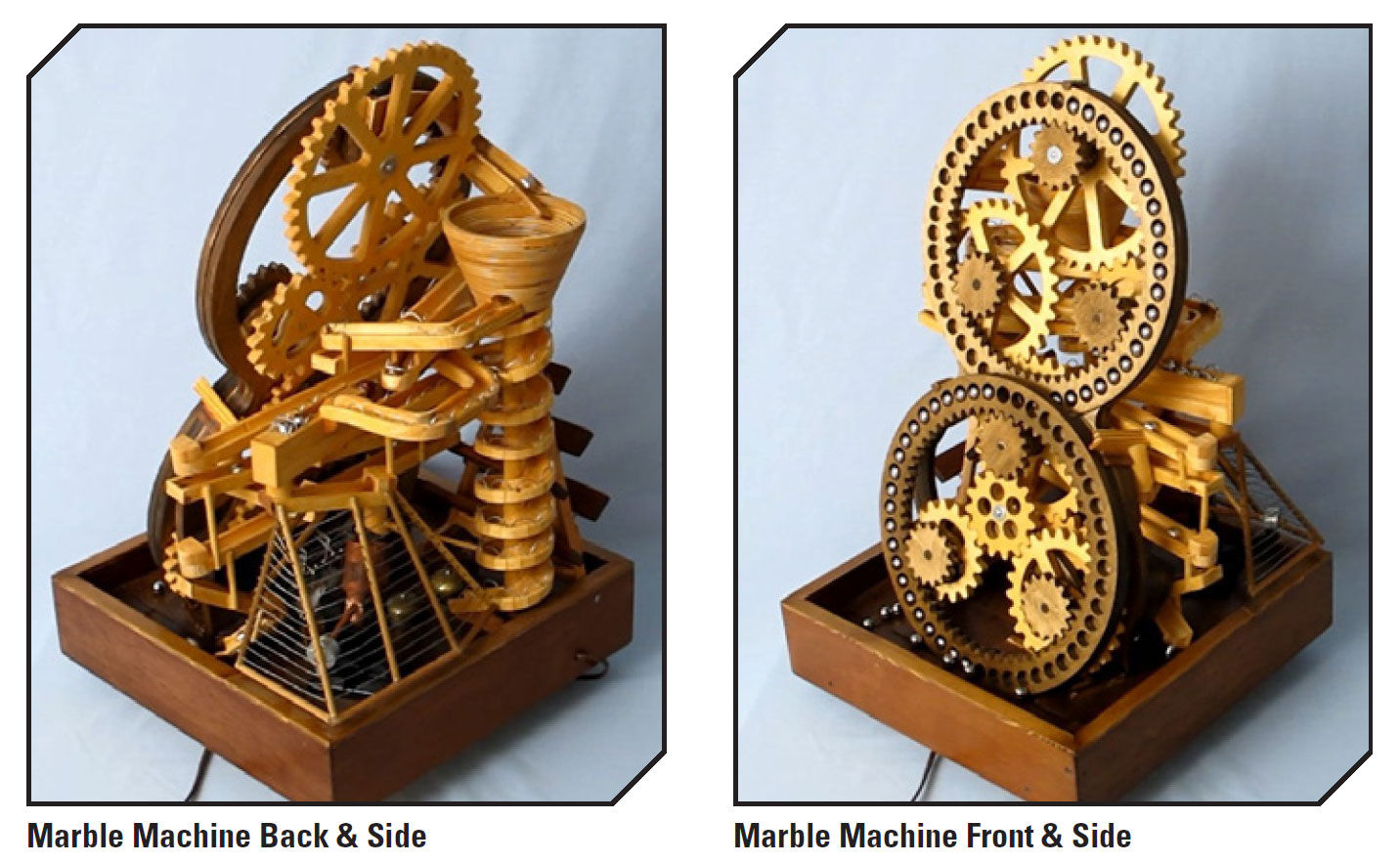

Gears that Transport Bearings for Entertainment

Ron Walters started building his wooden machine as a pastime after his foot surgery. Months later, the retired mechanical engineer had an entertaining device that featured 16 gears and could move ball bearings at a rate of 7,200 per hour.

The device, called a marble machine, holds 75 ball bearings, weighs 30 lbs., stands 30" tall, has a base 19" square, and includes two ring gears, each 14.5" in diameter.

All 16 gears move the ball bearings the 30" from the bottom of the machine to the top. Moreover, the two largest gears actually carry the bearings. They are identical ring gears, and they carry bearings in holes carved in their rims.

Starting at the machine’s base, each bearing rolls into a hole in the rim of the lower ring gear. The gear rotates clockwise, carrying its bearings upward. The bearings stay in their holes because the ring gear has a backing. The backing is circular and stationary, but with a hole at its top. So, as the lower ring gear rotates, each of its holes reaches the backing’s hole. When a gear hole lines up with the backing’s hole, a bearing transfers from the lower ring gear to the upper one.

Rotating counterclockwise, the upper ring gear has an identical backing with an identical hole at its top, which is also the top of the machine. So, when a gear hole lines up with the backing’s hole, a bearing rolls out of its hole and through the other hole.

Now at the top of the machine, a bearing starts its way back down by first rolling into a vortex funnel that looks like a flower pot. The funnel has three holes: one in the bottom of the funnel, two in the wall of the funnel. The two in the circular wall are diametrically opposite each other. If a bearing goes through the bottom hole, it rolls down a spiral track. At the bottom of this path, the bearing rings two old, brass telephone bells.