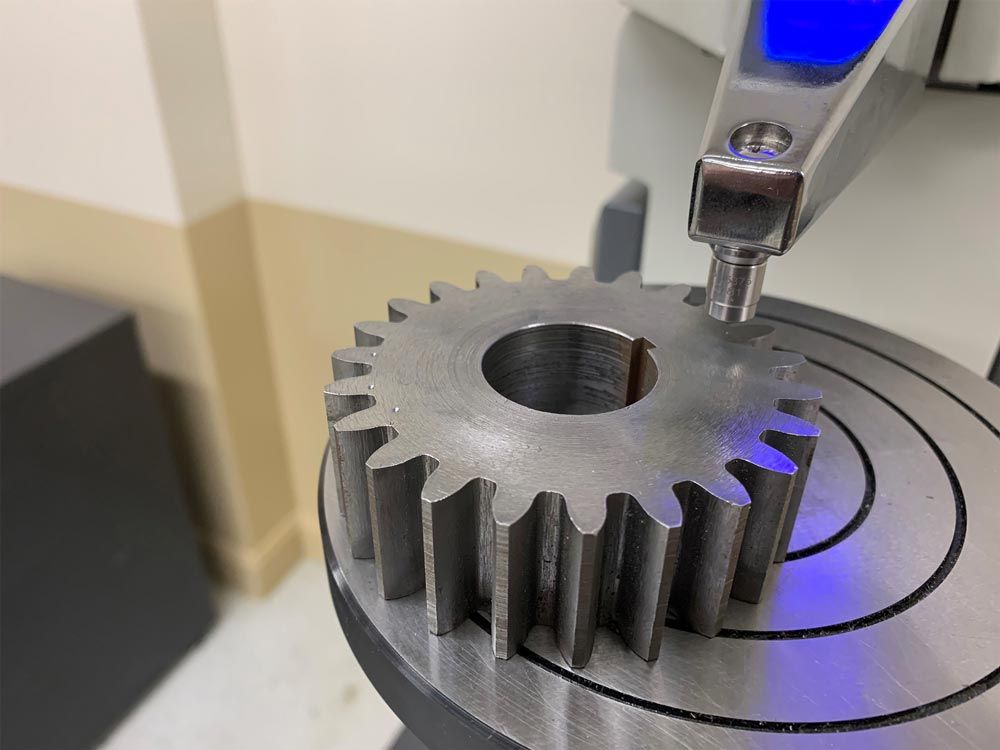

Hardness Testing Gears — Know Your Options for Best Results

Gears must be manufactured to withstand extreme forces and challenging conditions, so hardness testing to determine material integrity is key. Understanding the different hardness testing types and systems can be useful to determine an optimal solution. Hardness testing functionality has evolved and now users can dial into world-class caliber instrumentation which more closely aligns with their applications at hand.

Hardness Testing Defined

One of the most common indentation hardness tests used today is the Rockwell hardness test, and although less widespread, the Brinell and Vickers hardness tests are also utilized. The majority of indentation hardness tests measure the deformation that occurs when the material being tested is penetrated with an indenter. Two levels of force are applied to the indenter at specified rates and dwell times when performing a Rockwell hardness test. This is different than the Brinell and Vickers tests, where the size of the indentation is measured after the indentation process. The Rockwell hardness of the material is based on the difference in the depth of the indenter at two specific times during the testing cycle. The value of hardness is calculated using a formula that was derived to yield a number falling within an arbitrarily defined range of numbers known as a Rockwell hardness scale.

Regardless of the Rockwell scale or indenter being used, the overall Rockwell test procedure is the same. The majority of today’s newer machines automatically perform the entire test. Also, when leaving a mark or indentation is not an option, nondestructive ultrasonic technology can be used.

Rockwell Hardness

When testing the hardness of carbon steel, alloy steel, cast iron, nonferrous metals and engineering plastics, digital Rockwell benchtop hardness testers can be used to directly measure in the most popular regular Rockwell hardness scales and can quickly convert that hardness value into HB, HV, HK and many other scales. Desirable hardness tester features include the ability to obtain ultra-precise results, a wide measuring range, and scale/selectable test force capabilities. Also, automatic main test force loading/unloading, a high-resolution digital display and USB data storage are all very advantageous.