IGS to Increase Wind Gearbox Torque Density

To increase cost efficiency in wind turbines, the wind industry

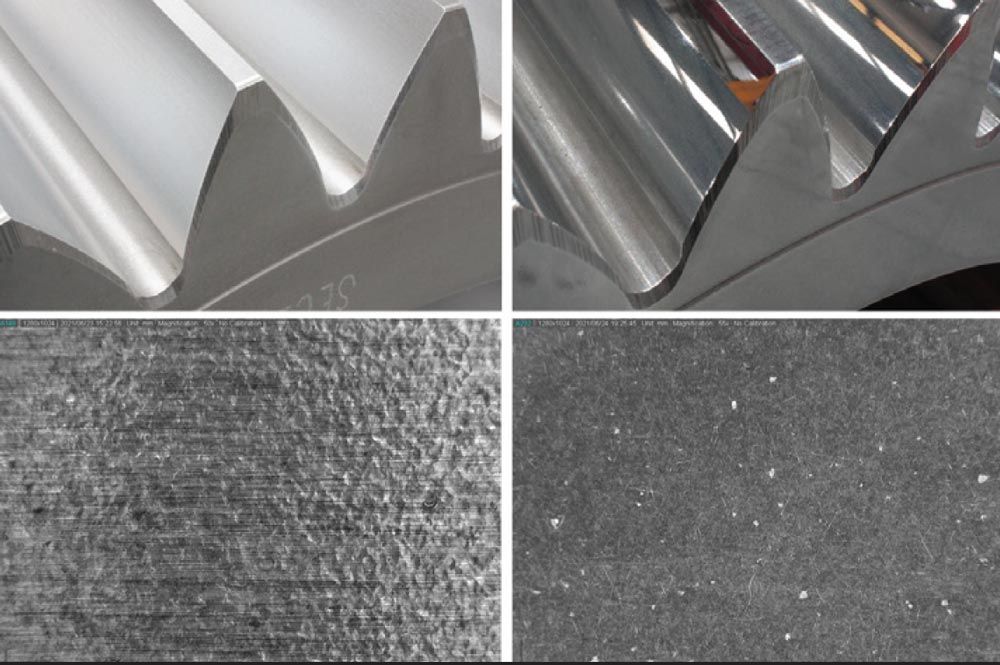

has seen a significant rise in power density and an increase in the overall size of geared components. Current designs for multimegawatt turbines demand levelized cost of energy (LCOE) reduction, and the gearbox is a key part of this process. Since fatigue failures nearly always occur at or near the surface, where the stresses are greatest, the surface condition strongly affects the gear life. Consequently, an improved surface condition effectively avoids major redesign or increased material cost due to an increase in part size. Additional finishing methods such as shot peening (SP) and superfinishing (SF) significantly increase the gear load capacity, but these effects have not yet been adequately considered in the current ISO 6336 standard or in any other gear standards. The combination of SP followed by SF will be described here as an “improved gear surface” (IGS).