Keeping Up with Manufacturing Changes

PrimeTurning machining method supports competition among manufacturers

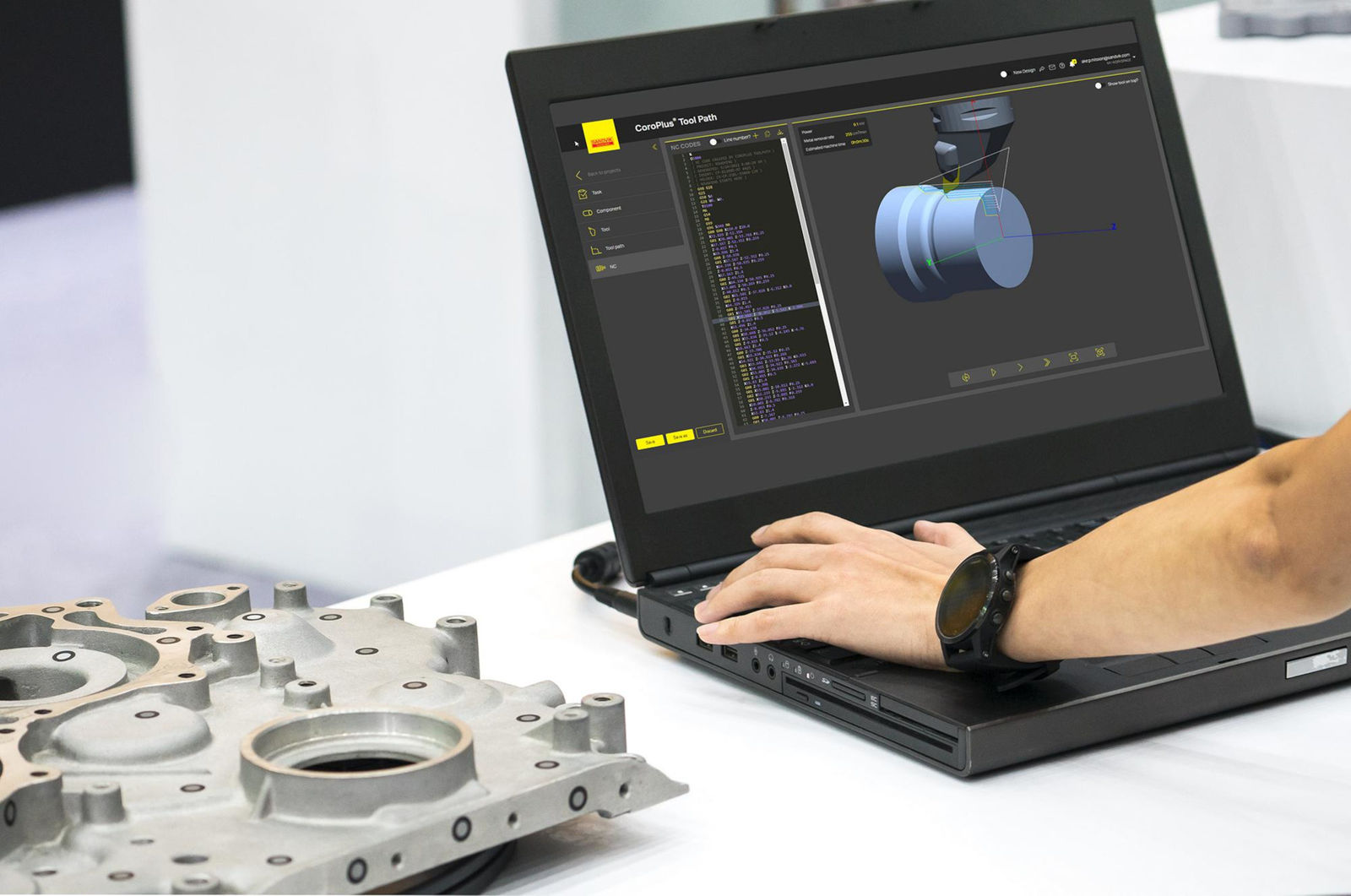

The rise of electrification is happening more widely and suddenly than anyone expected, both for automobiles and for other types of electric vehicles (EVs). The global EV landscape is also more competitive than the automotive markets of previous decades, as more manufacturers—large and small—compete for space. How can manufacturers stay ahead of the competition while also overcoming the increasing challenges posed by difficult-to-machine materials, like high-strength steel? A new all-directional tooling method, combined with the next-generation CoroTurn Prime B-type insert from Sandvik Coromant, holds the answer.

The electric vehicle (EV) markets are shaping up to be more diverse as larger, established companies like Porsche compete with smaller manufacturers. (Shutterstock)

The electric vehicle (EV) markets are shaping up to be more diverse as larger, established companies like Porsche compete with smaller manufacturers. (Shutterstock) From the mid-1930s, the “Big Three” manufacturers dominated the U.S. automotive market: General Motors, Ford, and Daimler Chrysler. This continued for the next 70-plus years. But competition among carmakers is changing—both within the U.S. and in the current world-leading markets for EVs: Asia-Pacific, followed by Europe. As written by Matthias Holweg in “The Evolution of Competition in the Automotive Industry,” a chapter from the book Build To Order: The Road to the 5-Day Car, “Competition has shifted from cost-leadership during the heyday of Ford’s original mass production, to variety and choice [and then] to diversification through leadership in design, technology or manufacturing excellence.”

This also applies to the EV markets. They are shaping up to be more diverse and competitive than the automotive markets of yesteryear as larger, established companies like Porsche compete with small, globally expanding manufacturers like Polestar. On the world stage, these companies need to catch up with China—indeed, six of the 10 best-selling plug-in EVs worldwide were from Chinese brands in 2021, according to Statista.

For original equipment manufacturers (OEMs), the competitive markets are shifting the demands placed on components. EVs have fewer components, which are smaller, and lighter, and must withstand higher levels of torque from the electric engine. The components must support greater energy efficiency and a higher power density. This, of course, puts high demands on the components, leading to a shift in material technology.

Sandvik Coromant’s specialists expect this shift to include a continued increase in the use of high-strength steels, from around 15 percent of all materials used in automotive manufacturing in 2010 to 38 percent in 2030. These new materials, including clean and ultraclean steels, are made from alloying elements and are able to withstand the aforementioned challenges—like higher levels of torque from the electric engine—because they have fewer metallurgical impurities.

But how does this relate to machinability? With clean and ultraclean steels, we see an increase in the plasticity of the material, as the reduced impurities in the steels translate to machining challenges relating to chip breakability and removal. These materials have a higher yield strength that, in turn, requires higher cutting forces during machining and creates higher levels of tool wear. While high-strength, clean, or ultraclean steels are more difficult to machine, the growing integration of digitalization and computer-aided manufacturing (CAM) on production lines is setting the bar higher for manufacturing quality and efficiency.