Krebs & Reidel Offer Premium Grinding Wheels with High Process Reliability

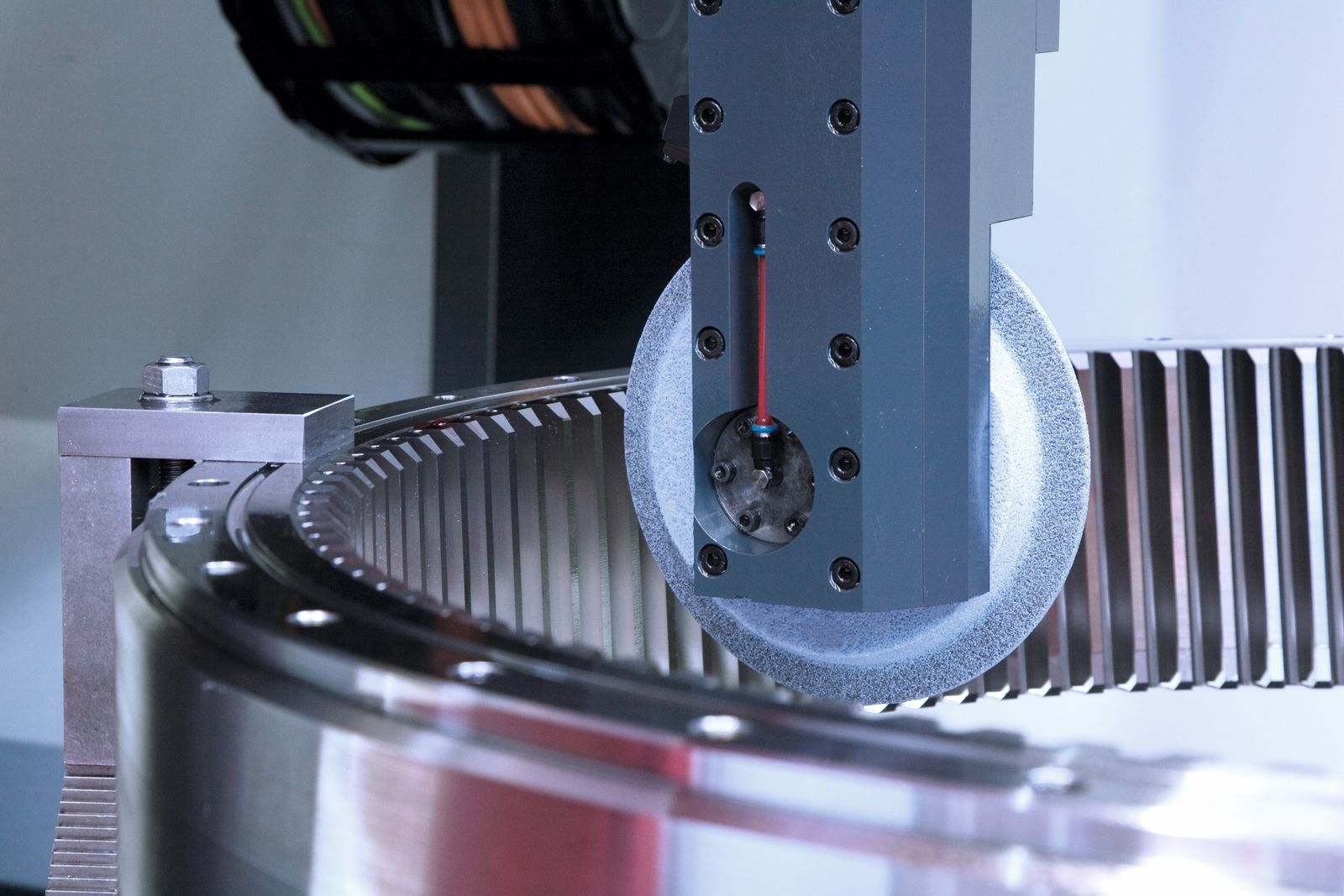

Serial production of large gears requires a high level of quality, excellence, and continuity in production. Emphasis is placed on maximum synergy between the grinding machine, the grinding process, and the grinding wheel. After several successful trials on various Klingelnberg Höfler Rapid grinding machines carried out by Krebs & Riedel with customers in their production facilities, Krebs & Riedel has received several large orders for grinding large gears from abroad and has introduced the new premium grinding wheels with high process reliability.

Krebs & Riedel is expanding into other sectors where large gears are manufactured with the new Blue Moon TZ premium product range.

Krebs & Riedel is expanding into other sectors where large gears are manufactured with the new Blue Moon TZ premium product range.Krebs & Riedel is a manufacturer of grinding wheels for gear grinding in the automotive and EV sector. The family-owned company is also expanding into other sectors where large gears are manufactured with the new Blue Moon TZ premium product range.

In recent years, wind power has been an important factor in reducing CO2 emissions. Wind turbines are getting bigger and more powerful, while production costs must be reduced. This requires production methods that can produce the gears cost-effectively and in high quality, even with complex flank modifications. Gear sizes in wind power typically range from 800 to 4,000 mm. Some gears can even reach a diameter of 8,000 mm and weigh up to 100 tonnes. The most common size in the field of external gears is 1,200 mm in diameter and ranges from module 12 to module 52. The profile grinding wheels typically have a diameter of 100–450 mm.

Blue Moon TZ is comparable in performance to other precision-shaped abrasive gains on the market. It is self-sharpening, very sharp-edged, microcrystalline and has an elongated trapezoidal shape.

Blue Moon TZ is comparable in performance to other precision-shaped abrasive gains on the market. It is self-sharpening, very sharp-edged, microcrystalline and has an elongated trapezoidal shape.Synergy between the grinding machine, the grinding process and a premium grinding wheel is very important. Only a perfectly ground gear geometry ensures optimum power transmission for high wind turbine efficiency and smooth running. Grinding burn must be avoided under any circumstances, because the forces in the gearbox are very high and tooth breakage is very expansive. High-precision gear quality is a matter of course at Klingelnberg and Krebs & Riedel. It increases the service life of the individual gear components and makes a significant contribution to reducing maintenance and production costs. To achieve maximum synergy between the grinding machine and the grinding wheel, Krebs & Riedel optimizes the process with application support at customers sites around the world and offers with the Blue Moon TZ, a new premium grinding wheel with a precision-shaped abrasive grain.

Blue Moon TZ is characterized by a very high cutting performance and a very high material removal rate.

“In some trials, the material removal rate (Q'w) was more than 30 mm³/mms,” said Sigurd De Ridder, senior application engineer at Krebs & Riedel, who conducts trials and process optimization for customers worldwide. “Precision-shaped abrasive grains are state of the art today. Blue Moon TZ is comparable in performance to other precision-shaped abrasive gains on the market. It is self-sharpening, very sharp-edged, microcrystalline and has an elongated trapezoidal shape.”