For a short time, anyway, I felt like I was at the center of the

gear universe.

Creating and maintaining contacts like these helps us continue

to fulfill our role as “The Gear Industry’s Information

Source.”

Another way we build on that role is by continuing to expand

our information offerings to you, the gear community. At Gear

Expo, we did so by presenting the first ever live and in-person

sessions of “Ask the Expert.” At our booth, we hosted four sessions,

with three or four renowned experts in each session. The

topics were “gear grinding,” “cutting tools,” “gear design” and

“ask anything.”

Some of the foremost authorities in the world were among

our experts during the live sessions, and they attracted a crowd

to our booth throughout the show. Even though I’ve been in

the gear manufacturing industry for more than 50 years, I was

delighted by the expertise of the presenters and the sophistication

and depth of their responses. Many of our panelists are

only available during a show like this on a very limited basis,

often only to the largest of customers. To have them all together

and be available to the industry at large was truly a first in our

industry. Please see the article on page 92 for a rundown of the

sessions, including the names and titles of the panelists, the

questions asked and where to go online to view each of the video-

recorded sessions.

The excitement we carried back home from Gear Expo was

about more than just our own experiences at the show. Even

outside our own activities, it was one of the best shows in recent

memories. Foot traffic was good, and many exhibitors reported

that the attendees came to the show with specific requirements,

and orders were received. We heard similar reports out of EMO

in September. So the anecdotal evidence, at least, points to a

reasonably healthy gear industry for the immediate future.

The empirical evidence might be a little more mixed, as you’ll

see in our annual State of the Gear Industry survey results (page

26). As many of you are aware, there are major segments of the

gear manufacturing community — namely mining and energy

— that are less than robust, while others — like automobiles

and aircraft — are rolling along like a precision ground gear.

According to the survey results, the American gear industry

seems to be in decent shape, with the overall level of optimism

about the same as last year.

But there are pockets of trouble, to be sure. In particular, our

respondents outside North America were decidedly more pessimistic

this year, and many respondents continue to express concerns

about the difficulty in finding skilled labor.

We’ll continue to do our part by continuing to provide as

much educational material as possible, in as many formats as

we’re able. How can you help assure this information keeps flowing

to you and your associates? You can do your part by renewing

your free subscription. Just visit www.geartechnology.com and

click on “Subscribe” in the upper-left corner, and encourage all of

the young and new people in your organization to do the same.

Make sure they’re aware that more than 31 years of gear-related

education is available on our site for free, including our very popular

“Back to Basics” series we ran in our first five years, explaining

the mechanical interrelationships of tools and machines. Just

type “basics” in the search bar to get a good start.

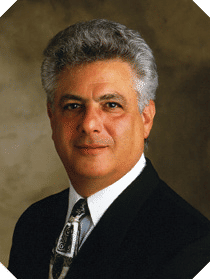

About Author

Michael Goldstein, Publisher & Editor-in-Chief,

began his career in the gear industry in 1964,

when he joined his father at Cadillac Machinery

Co., Inc. As a machine tool dealer specializing in

Gleason bevel gear machines, Michael rose to

prominence in the industry, with leadership roles

in the Machinery Dealers National Association

(MDNA), as well as the European Association of

Machine Tool Merchants (EAMTM). He founded

Gear Technology in 1984, and has been involved

with the American Gear Manufacturers Association

(AGMA) throughout his career. [50 years in the gear

industry]