An example could be supplying remote access to a machine on the shop floor, enabling operators to check or control different elements. For example, cameras and other internal sensors, not just the controller, can be installed and connected to receive notifications in case of anomalies as well as interact with assets to maximize uptime, productivity, and efficiency. Once this project is successfully completed, then it is possible to move on to the next area, identifying where more value could be added to a process.

This approach is therefore ideal for small to medium enterprises, as it offers a sustainable pathway to drive continuous improvement and competitiveness in a fast-paced marketplace. When implementing a stepwise strategy, it is fundamental to select suitable solutions that support it by offering the level of flexibility and scalability required. More precisely, specifying a network technology for future machines that can support interoperability and interconnectivity on small and large scale is key.

“TSN is highly recommended when embarking on a digital transformation journey and modernizing the architecture of your machines. By doing so, companies can make sure they will be able to support both information technology (IT) and operational technology (OT) communications on the same network while delivering reliable, unmatched performance in data sharing. This means that they will be able to smoothly integrate any asset they want at any stage of their digitalization,” Alvarado said.

This solution is a future-oriented platform for industrial communications that can help companies create Connected Factories. As an open technology, it offers maximum compatibility and interoperability, so that devices, machines, or lines can be connected to each other, regardless of their vendor. This capability further optimizes flexibility and costs for small to medium businesses.

By specifying CC-Link IE TSN to futureproof operations, companies can make sure they are using the most suitable backbone to support any application related to the connected industries, such as remote control, IIoT, and digital twins.

“In effect, they can benefit from a considerable leap forward in realizing smart operations where data-driven insights are used to improve productivity, efficiency, flexibility, and responsiveness. Even more, businesses can do this in a stepwise approach making targeted investments in terms of cost, time and resources while considerably enhancing their competitiveness,” Alvarado added.

cc-link.org

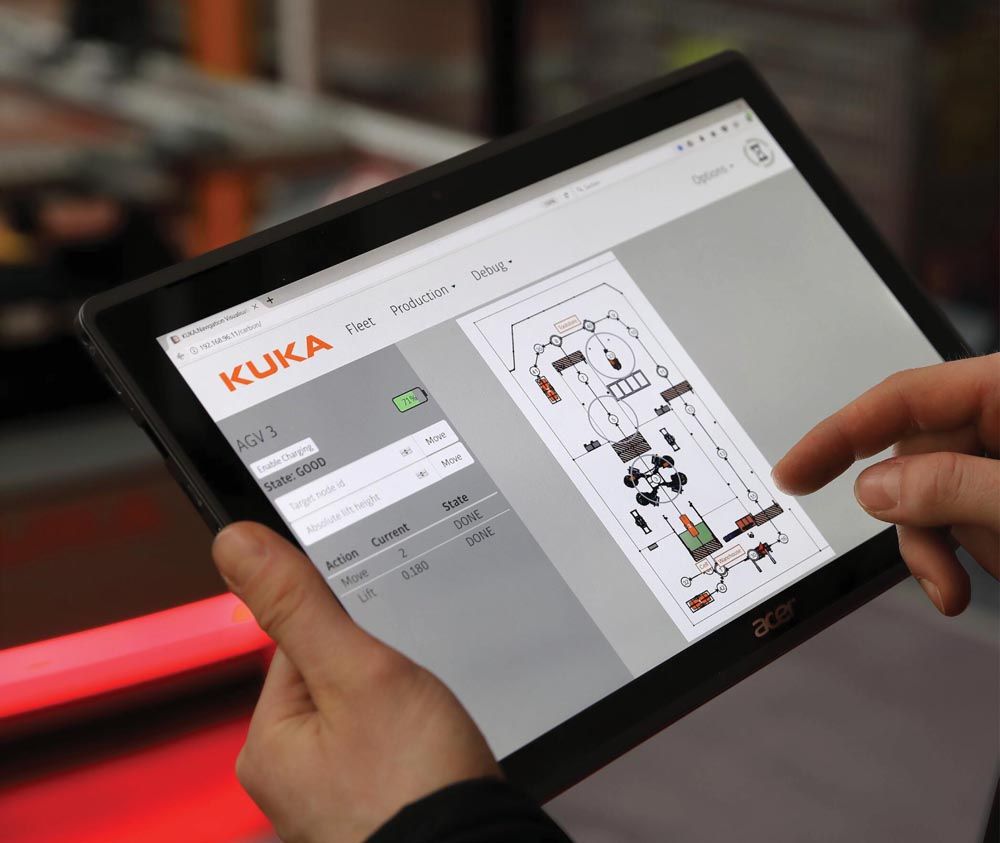

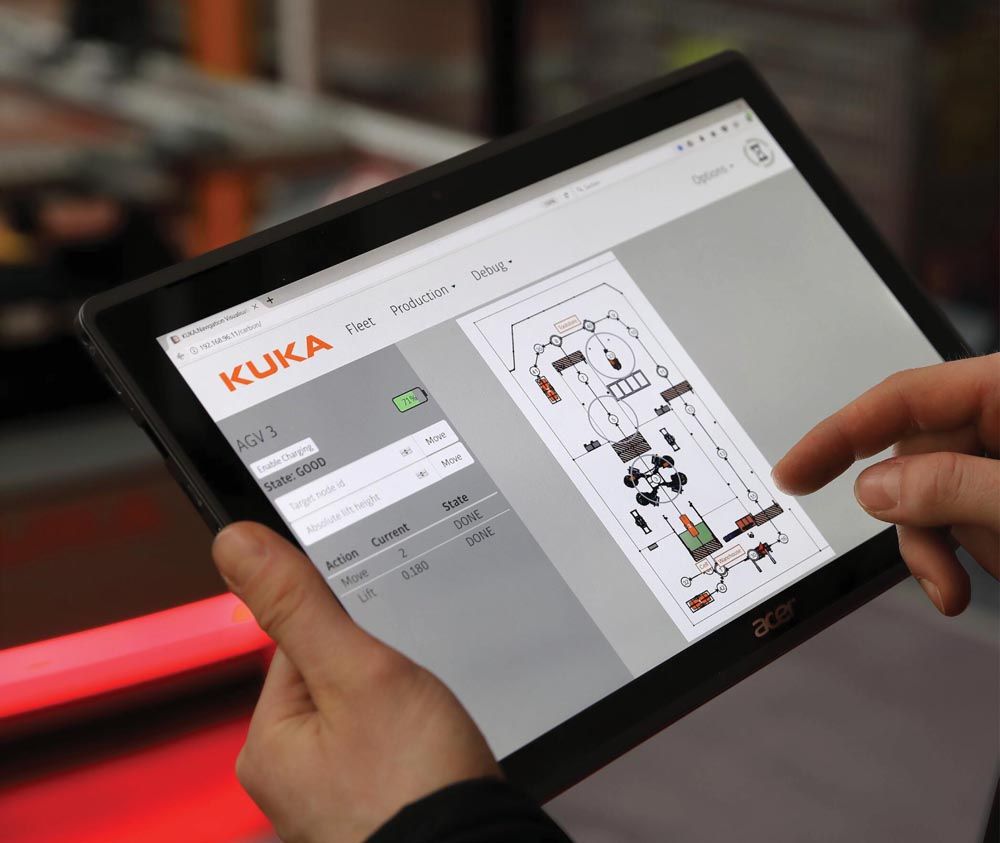

Robotic Simulation in Minutes with KUKA

KUKA’s advanced automation planning software, KUKA.Sim allows manufacturers to accurately plan their automation solutions before the system has even been put into operation. Robot motion sequences are programmed offline, depicted in real time, analyzed, and perfected to ensure that processes and work cell layouts can be implemented as planned.

KUKA.Sim creates a digital twin and identical image of the proposed production process that becomes the basis for virtual commissioning of production lines. The offline commissioning capability saves time, improves planning reliability and verification, and increases sales. KUKA’s simulation of a robot system with KUKA.Sim is conducted in just a few minutes without deep programming knowledge.

KUKA.Sim is based on a modular software architecture—with an efficient, flexible and durable toolbox principle. The basic package can be expanded with three add-ons: for powerful modeling of an individual component library, for virtual commissioning and for simulation of welding applications. This means customers only pay for the functional expansions they need. If their requirements change, users can easily add further add-ons in the future. The modular system stands out for its flexibility and durability.

VR hardware can offer a virtual demonstration of your system concepts and machining cells. These simulation results can be viewed on a mobile device—smartphone or tablet—through an app.

Additionally, KUKA has been actively promoting its intelligent machines and IIoT strategies at recent trade shows.

KUKA recognized the potential of networked and open automation systems back in the 1990s. Engineers believe that no robot today has any future unless it is capable of being integrated into complex, networked production systems based on standardized mainstream technologies.

Intelligent robots—in a variety of forms and configurations—are leading this evolution. They will not only be tethered within cells as we knew them in the past, but provided with new intelligence, apps that are simple to integrate and give them new capabilities at a click, or cloud-based functions that turn them into active players in the flexible, autonomously operating smart factory.

Machines must accomplish three things: they must carry out their task as efficiently as possible, be able to adapt to new framework conditions, and be capable of sharing this knowledge with processes and systems in an intelligent way.

kuka.com

Upgrading Robotic and Automation Performance with Yaskawa

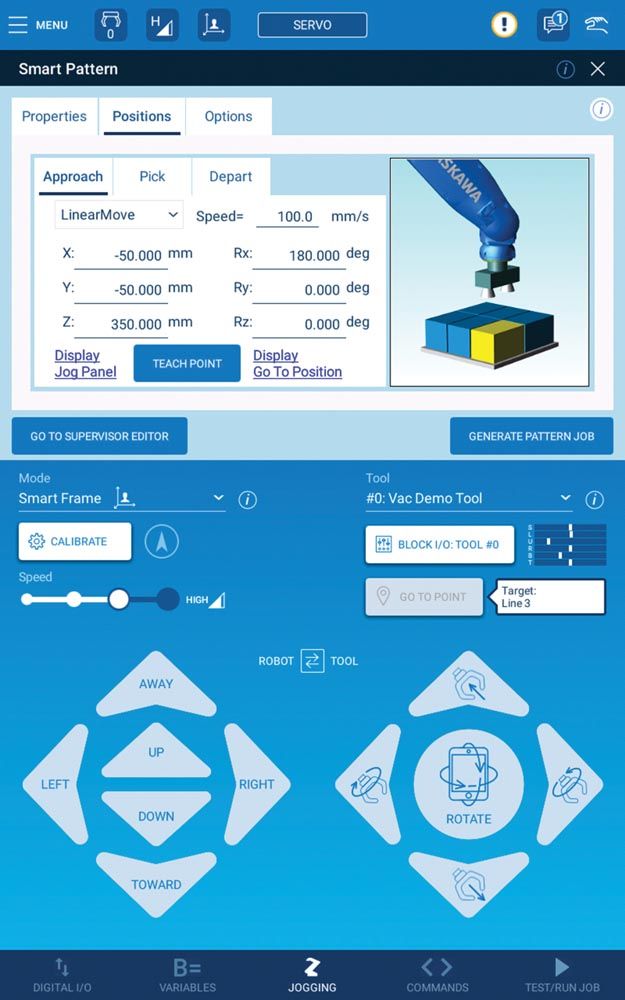

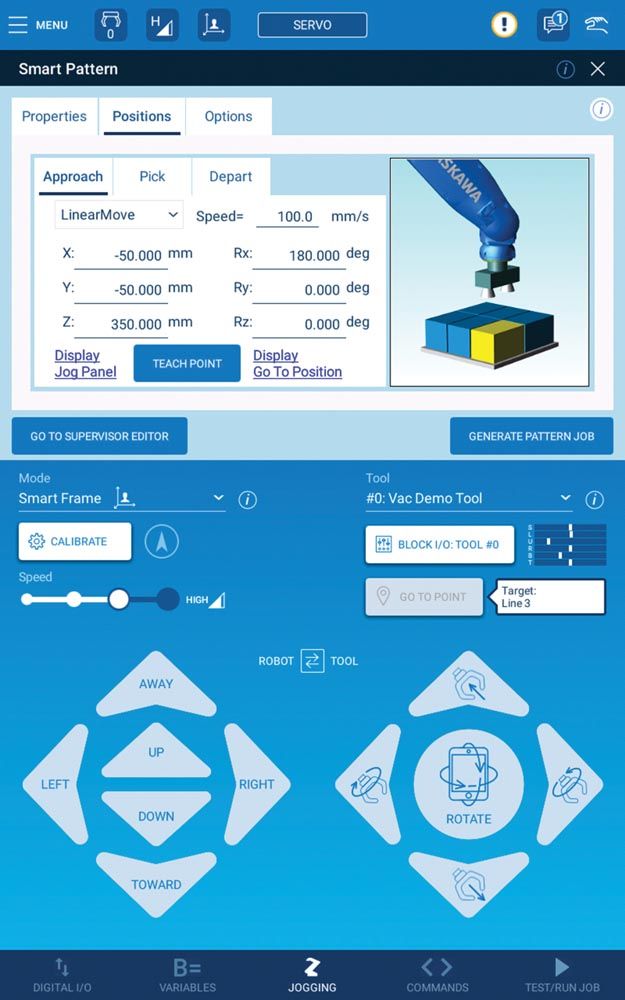

Featuring multiple improvements and optimization, Yaskawa’s Smart Pendant v2.1 software extends capability for quick robotic implementation of basic assembly, injection molding, inspection, machine tending, material handling, and pick and place tasks.

Enabling previously unsupported functions, Smart Pendant v2.1 provides a built-in classic interface view. Ideal for more experienced robot operators, this option enables the end user to reset minor and major alarms or to edit concurrent I/O with reduced programming downtime.

Expanding on the performance improvements and extension app capabilities introduced previously, Smart Pendant v2.1 improves configuration and programming of third-party devices, including Yaskawa’s Smart Packager software development kit (SDK). This desktop tool enables third parties to combine multiple components into a single convenient file. Each file, known as a Yaskawa installation package (YIP), enables easier robot setup by automating processes typically outlined in a manual.

Various advances, such as YRC1000 controller software updates, multitouch jogging, 3D viewer optimizations, basic concurrent job support, improved HC-series configuration and other INFORM usability improvements are also included.

Smart Pendant is available for use with select Yaskawa Motoman YRC-controlled robots. Soft Pendant software—a digital version of the YRC1000 pendant that can run on a Windows operating system—is also included.

Expanding Smart Pendant capability for handling tasks, the easy-to-use Smart Pattern extension enables quick development of jobs for repetitive handling tasks. Ideal for common tasks like stacking, unstacking, case packing, machine loading and unloading, this intuitive interface supplies guided prompts for single part, grid (2D array), 3D grid (3D array) and stack patterns.

Prompts are supplied to create two types of jobs. Pattern jobs define a specific pattern and robot movement for managing each part in the pattern. Supervisor jobs define which patterns should be used to pick and place parts, as well as the overall flow of the system, including basic I/O signals.

Easily customizable, job editing is available to accommodate specific system requirements. A wide variety of grippers and end-of-arm tooling can be used.

Compatible with the YRC1000 and YRC1000micro controllers, Smart Pattern is available as a complimentary download for use with HC-series and GP-series robots.

This technology can increase production and efficiency for shops in areas like arc welding, assembly, machine tending, machining, material removal, packaging, part transfer and more.

motoman.com

Just Scratching the Surface

As IIoT solutions increase in the industrial sector, manufacturers—through the cloud, A.I., augmented reality and other technologies—will have easier access to machine data in real-time. This can lead to more automated processes as well as an overall improvement in productivity. As these systems and suppliers continue to share data—a facility where products, systems, machines, and management harness advanced analytics can accelerate innovation. This is the common thread throughout IIoT implementation. These development tools and training will become more readily available to allow management to find faster, more efficient manufacturing solutions in the future.