NUM and Lanzi Collaborate on Retrofitting a Gear Hobbing Machine

If the cost difference is small, the customer will always purchase a new model machine rather than a retrofitted one. However, when the price difference becomes greater, the conversation changes dramatically.

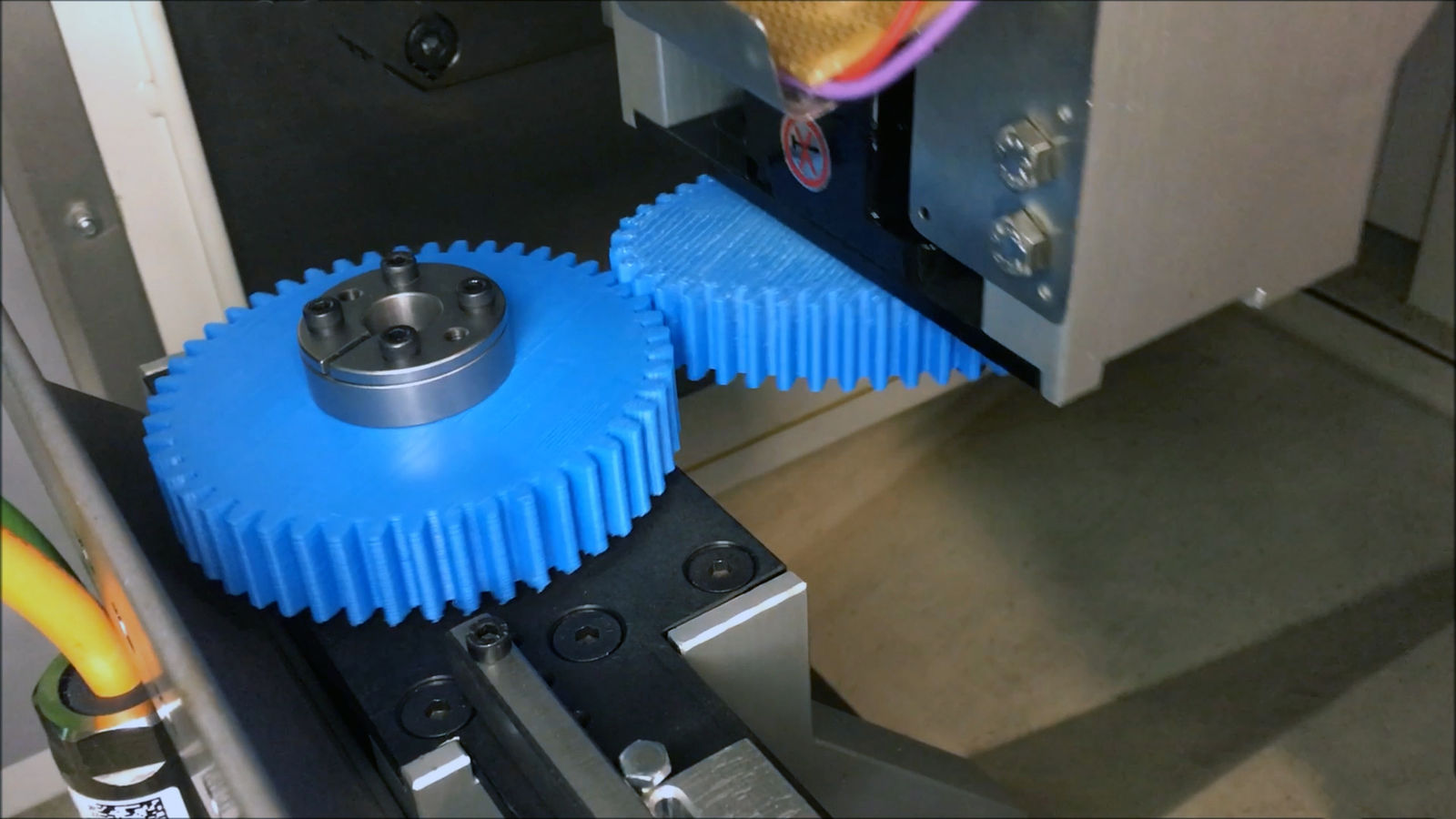

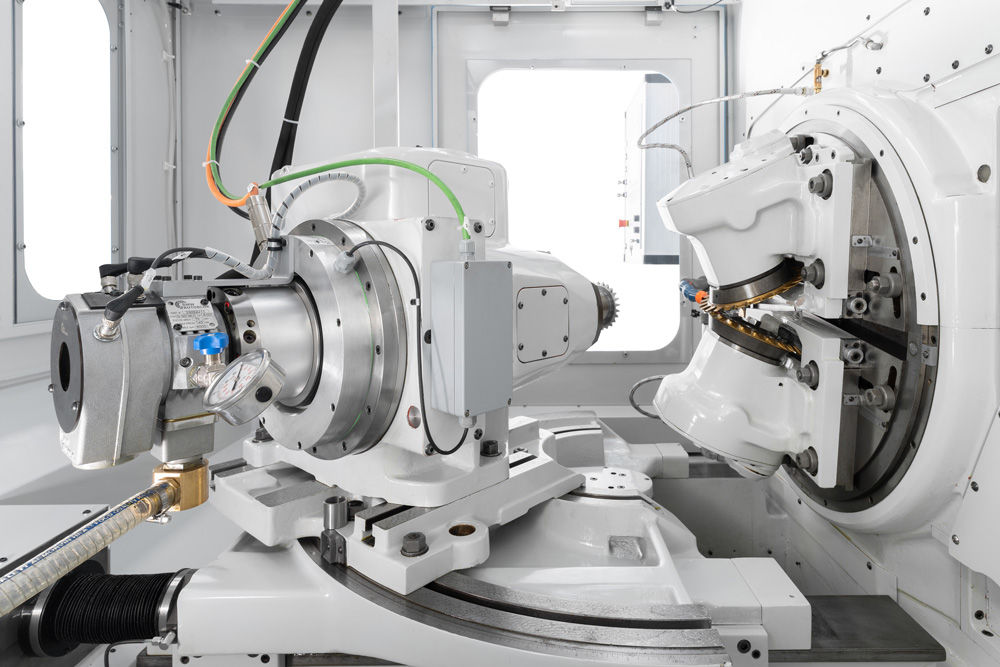

This is exactly why thirty years ago the company Lanzi – Manutenzioni e Retrofit from Emilia in Italy began offering retrofits on machines, and specifically on gear-cutting machines thanks to an ingenious idea of Gian Luigi Lanzi, from the second generation of the family. The retrofit challenge is far from simple, but one which has evolved over the years relying on a technological partnership with NUM. Retrofitting a gear hobbing machine, including changing the operating concept, is a very complex operation that requires specific know-how and technical skills at the highest level.

Lanzi - Manutenzioni e Retrofit was founded over fifty years ago in 1964 by Francesco Lanzi who specialized in the maintenance of traditional machines like lathes and milling machines. About twenty years later, Luigi Lanzi, from the second generation of the family, recognized a new and untapped market niche and gradually shifted the company’s core business from the original segment to the field of modernizing gear-cutting machines. This is when the company first began collaborating with NUM. The new focus of the company, based in Ozzano dell’Emilia (province of Bologna), is still the same today: retrofitting gear cutting machines, with particular attention to the bevel gear sector, and including spiral and spur gears.

“There is a significant difference between the purchase price of a new machine and the retrofit of a hobbing machine,” said Federico Lanzi, who has been managing the company alongside his father in the third generation since 2007. “Of course, the retrofitted machines have a slightly lower output, typically a production deficit of about 30 percent, but that doesn’t change the fact that the end user can buy three [or], four hobbing machines [for the same budget] instead of just one. So, if the customer does not have space problems in his plant, buying a retrofitted hobbing machine is much more advantageous.”

It is also interesting to ask about the service life of a retrofitted gear hobbing machine. This is almost as long as that of a new machine, if not longer, due to the rather large cast iron machine beds with which the original machines are equipped in most cases. Today, when a hobbing machine leaves the Lanzi factory after a retrofit, it is basically a new Lanzi brand machine, CE certified and equipped with Industry 4.0 functions. This means that anyone who decides to buy such a machine can benefit from all the advantages they would get if they had bought a new machine.