The facility is a torque regenerative test rig that

locks torque in the loop via rotating torque applier. The test

gears have a 1:1 ratio. Facility speed and torque can be varied as

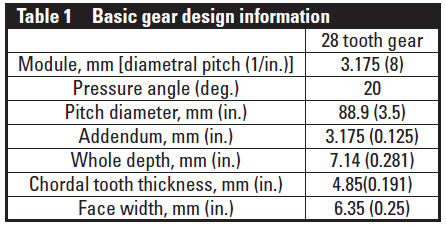

needed during a test. The basic gear design information of the

tested gears is listed in Table 1.

As previously mentioned, the facility went through an evolutionary

period (Ref. 5) where shrouding, visual access, gearbox

lubricant removal, and instrumentation were added to the test

section . A photograph of the current test gearbox arrangement

is shown in Figure 3.

_400.jpg)

Figure 3 Current test gearbox arrangement utilizing shrouds (bottom

exit shown).

- Click image to enlarge

Static shroud thermocouples were utilized during all tests.

High-temperature glass was also utilized as the outside shroud

to encase the gears. Ballistic plastic and another layer of hightemperature

glass provided visual (and video) access to the gears

during operation. Lubricant for normal operation was fed at the

into-mesh location through part of the shroud (Fig. 4). The normal

operational flow rate was approximately 0.42 l/min (0.11

gpm), at 207 kPa (30 psig) jet pressure, with the lubricant inlet

temperature of ~110°C (230°F). Instrumentation and normal

lubricant jet locations are shown (Fig. 4). A turbine engine with

drive system lubricant MIL-L-85734 was used during the testing

at hand.

_400.jpg)

Figure 4 Example of test gear arrangement with outer gearbox cover removed, top exit shrouds shown.

- Click image to enlarge

Testing Methodology

Prior to the reported loss-of-lubrication testing, the gears were

broken-in to allow normal run-in wear to occur. The gears were

operated for at least 1 hour at ~50 percent maximum torque and at

full facility speed (10,000 rpm). After this period the load was then

increased to the maximum load and run for at least several more

hours prior to conducting a loss-of-lubrication test. Most tests

were run until the teeth failed to continue to carry torque (plastically

deformed), or were stopped just prior to this condition.

During all tests the static instrumentation and live video were

carefully monitored. Data from all sensors were collected at 1

Hz and stored for post-processing.

Testing and Discussion of Results

The test results described in this report were from the same

lot of gears manufactured to the basic gear design information

provided in Table 1. The gear material was an aerospace gear

steel (Ref. 9) that was carburized and final-ground; the surface

roughness was 0.41 micro-meters (16 micro-inch) or better. The gears have some tip relief starting at the highest point of singletooth

contact and a small amount of crowning across the face

width that is symmetric.

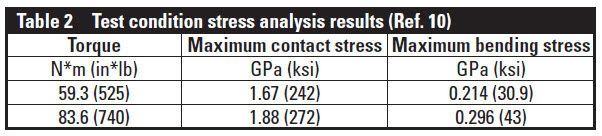

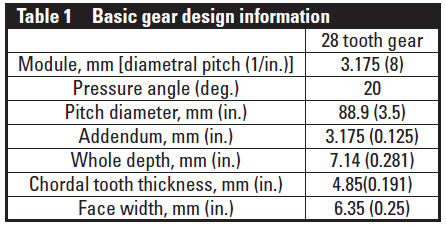

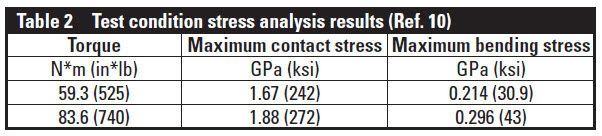

Five test results are described in this report. The tests in the

loss-of-lubrication condition were conducted at one of two load

levels, and are documented in Table 2. The basic gear design

information, along with the load level, produced maximum levels

of bending and contact stress, found via the analysis technique

in Reference 10.

An example of each of the two load levels will now be

described.

At the lower level of the two loads, two tests were conducted

with the loss-of-lubrication time of 40.8 and 43.1 min in length.

The data from the static thermocouples imbedded in the shrouds,

along with other facility temperatures, is shown in Figure 5.

_400.jpg)

Figure 5 LOL (loss of lubrication) data for 1.72 kPa (250 psi) load

pressure ~ 59.3 N*m (540 in*lb) torque tested at 10,000 rpm.

- Click image to enlarge

_400.jpg)

Figure 6 Post-test condition of the gears (gearbox cover and outer

high-temperature glass removed).

- Click image to enlarge

The gears in the post-test condition are shown in Figure 6.

Note that the test was conducted until the gear tooth meshing

heat generation and resultant temperature were high enough to

plastically deform the gear teeth. This type of post-test condition

occurred whenever the test was permitted to continue until

total loss-of-torque-delivery was achieved; a typical loss-oflubrication

failure at this condition is shown (Fig. 7).

_400.jpg)

Figure 7 Example of loss-of-lubrication test during final seconds of

operation.

- Click image to enlarge

_400.jpg)

Figure 8 Loss-of-lubrication data from higher load test 83.6 N*m (740

in*lb).

- Click image to enlarge

Two other tests were conducted at an elevated level of load,

i.e. — ~83.6 N*m (740 in*lb). These tests, in the loss-of-lubrication

mode, produced failures in 7.9 and 9.2 minutes. The test

temperature data from the 7.9-minute loss-of-lubrication test

is shown (Fig. 8). As can be seen from this data, the temperature

did not reach an increased steady-state condition prior to

increasing to failure, as it did in the test shown in Figure 5. After

the primary lubrication system was disconnected, the temperature

just continued to rise. The post-test condition of the test

gears is shown (Fig. 9) with the gearbox cover removed.

_400.jpg)

Figure 9 Post-test photograph of increased load test gears with outer

shroud high-temperature glass fractured.

- Click image to enlarge

Instrumented Gear Test

The most desired test for loss-of-lubrication behavior includes

employing on-component information. While it would be of

great benefit to have instrumentation at the gear-meshing sur-face, this has been shown to be very difficult to accomplish.

Even with full elastohydrodynamic film, the lubricant viscosity

of turbine engine lubricants — as used in rotorcraft drive systems

— is insufficient to develop films thick enough to keep the

on-surface instrumentation from wearing away. Therefore thermocouples

were installed at locations in areas of the gear where

contact does not occur.

The gear used in these tests is shown (Fig. 10); it is the gear

that was installed in the left side of the gearbox. The left-side

gear acts as the driving gear of the test section of the facility.

A total of five thermocouples were attached to the gear at: the

tooth tip mid-face width; root mid-face width; on the side of the

gear at the pitch radius; root radius; and mid-web locations. As

shown (Fig. 10), the thermocouple wires were covered by a thin

metal foil that was spot-welded to the side of the gear to protect

the instrumentation during operation. The rest of the required

hardware is shown (Fig. 11) prior to installation in the test rig;

the assembly in the test rig is shown (Fig. 12).

_400.jpg)

Figure 10 Instrumented LOL test specimen before testing.

- Click image to enlarge

_400.jpg)

Figure 11 Loss-of-lubrication test specimen and related components.

- Click image to enlarge

_400.jpg)

Figure 12 Test set-up for instrumented test gear.

- Click image to enlarge

The initial data for warm-up and operation of the facility

in the normal-to-loss-of-lubrication mode is shown (Fig. 13).

_400.jpg)

Figure 13 On-gear and out-of-mesh thermocouple data from start-up to

instrumentation failure during loss-of-lubrication.

- Click image to enlarge

During this same test the lubricant was shut off and the test run

until failure. The data from loss-of-lubrication initiation to failure

for the shroud (static) and other facility thermocouples is

shown (Fig. 14).

_400.jpg)

Figure 14 Data from shroud and facility (static) thermocouples.

- Click image to enlarge

The data in Figures 13 and 14 indicate that the bulk temperatures

of the gear were exceeding the temperature that was found

from the static shroud thermocouples. In the normal lubrication

condition this value was 20 to 40°F — depending on the location.

In loss-of-lubrication mode this amount was as much as 500°F

higher on the gear than that of the static shroud thermocouples.

In Figure 13 the data beyond 8,200" is believed to be invalid due

to post-test inspection of the thermocouple wiring that was melted

together at the common locations through the shaft. The thermocouple

wiring coating was exposed to bulk temperatures in the

gear beyond the melting point of the wire coating.

The post-test condition of the gears used in this test is shown

(Fig. 15). What can be noted is that a bending failure occurred

before the loss-of-lubrication test — as the failed tooth has no

evidence of running in this post-test condition. A hypothesis

is that tooth failure was initiated by a spot-weld in the root fillet

region from the thin metal protection strap that was used to

cover the thermocouple wiring.

_400.jpg)

Figure 15 Post-test condition after loss-of-lubrication test was

completed. Gearbox housing, slip ring and outer high

temperature glass removed.

- Click image to enlarge

_400.jpg)

Figure 16 Instrumented spur gear post-loss-of-lubrication test condition.

- Click image to enlarge

In Figure 16 the tooth that failed in bending shows no apparent

damage from loss-of-lubrication, since it occurred before

this lubrication condition was initiated. Upon closer examination,

the thin metal strapping used to overcoat the wiring that

was spot-welded to the tooth was found to be the initiation site

of the bending failure. Future testing of hardware for this purpose

will not have this as a hold-down feature for the tooth

root-fillet area.

Conclusions

A series of five loss-of-lubrication tests were conducted in an

aerospace-simulated environment using consistent sets of test

hardware. Following is a summary of the test results:

Applied torque can have a drastic effect on loss-of-lubrication

time. An increase of torque by 40%, 59.3 to 83.6 N*m (525 to

740 in.-lbs), resulted in a decrease in loss-of-lubrication operation

time by 75% (42 to 8 min).

Operation in loss-of-lubrication mode at lower torque produced

an elevated steady-state temperature condition. The higher

torque level did not have this operating time at an elevated

steady-state temperature condition. During the higher torque

tests the temperature continued to increase until failure of the

teeth.

On-component thermocouple data revealed that the gears

under normal conditions have bulk temperatures that are 20 to

40°F higher than the fling-off temperatures measured by the

static shroud thermocouples.

On-component thermocouple data indicated that during

loss-of-lubrication, conditions bulk temperatures on the gear

are from 150° to 500°F higher at certain times during this test

mode, when compared to the static shroud temperatures.

References

- ADS-50-PRF. “Aeronautical Design Standard, Rotorcraft Propulsion

Performance and Qualification Requirements and Guidelines,” U. S. Army

Aviation Troop Command, April 1996.

- Handschuh, R. “Thermal Behavior of Spiral Bevel Gears,” NASA–

TM-106518, ARL-TR-403, January 1995.

- Morales, W. and R. Handschuh. “A Preliminary Study on the Vapor/Mist

Phase Lubrication of a Spur Gearbox,” NASA TM-1999-208833, February

1999.

- Morales, W., R. Handschuh and T. Krantz. “Feasibility Study of Vapor-Mist

Phase Reaction Lubrication Using a Thioether Liquid,” NASA/TM—2007-

215035, December 2007.

- Handschuh, R., J. Polly and W. Morales. “Gear Mesh Loss-of-Lubrication

Experiments and Analytical Simulation,” NASA/TM—2011-217106,

November 2011.

6. Oswald, F. “Mechanical Components Branch Test Facilities and Capabilities,”

NASA/TM—2004-212722, January 2004.

- Krantz, T. and A. Kahraman. “An Experimental Investigation of the Influence

of the Lubricant Viscosity and Additives on Gear Wear,” NASA/TM—2005-

213956, ARL-TR-3126, October 2005.

8. Krantz, T. “The Influence of Roughness on Gear Surface Fatigue,” NASA/

TM—2005-213958, October, 2005.

- Pyrowear Alloy 53. Carpenter Technology Corporation, AMS 6308B.

- Vijayakar, S. and S. Abad. Helical 3-D User’s Manual, Advanced Numerical

Solutions, Hilliard, OH, February 2005.

About Author

Dr. Robert F. Handschuh has over

30 years of experience with NASA and

Department of Defense rotorcraft drive

system analysis and experimental methods.

He has served as the Drive Systems team

leader for the Tribology & Mechanical

Components Branch at NASA Glenn

Research Center in Cleveland, Ohio for

over 15 years, and currently leads the research there in

high-speed gearing, including windage, loss-of-lubrication

technology, and hybrid gearing. Handschuh is credited with

successfully developing many experimental research test

facilities at Glenn, and has conducted testing in the following

areas: high-temperature, ceramic seal erosion; blade-shroud

seal rub; planetary geartrains; spiral bevel gears and face

gears; high-speed, helical geartrains; single-tooth-bending

fatigue; and high-speed gear windage.

Lucas J. Gargano is a NASA Glenn Research Center

LERCIP intern.

_400.jpg)

_400.jpg)

_400.jpg)

_400.jpg)

_400.jpg)

_400.jpg)

_400.jpg)

_400.jpg)

_400.jpg)

_400.jpg)

_400.jpg)

_400.jpg)

_400.jpg)

_400.jpg)

_400.jpg)

_400.jpg)

.jpg)