Three Configurations: Affolter Gear Hobbing Machine AF160 Offers Versatility

When developing the AF160, maximum versatility was the key goal of the Engineering Department of the Swiss family enterprise Affolter Group, a world technology leader in high-precision gear hobbing solutions. Vincent Affolter, Managing Director of the Affolter Group, explains: “The AF160 is designed for high precision manufacturers that need flexibility and efficiency. With its eight axes, sophisticated automation solutions, and an innovative quick-change system, the machine provides exactly that.”

3 Gear Cutting Configurations

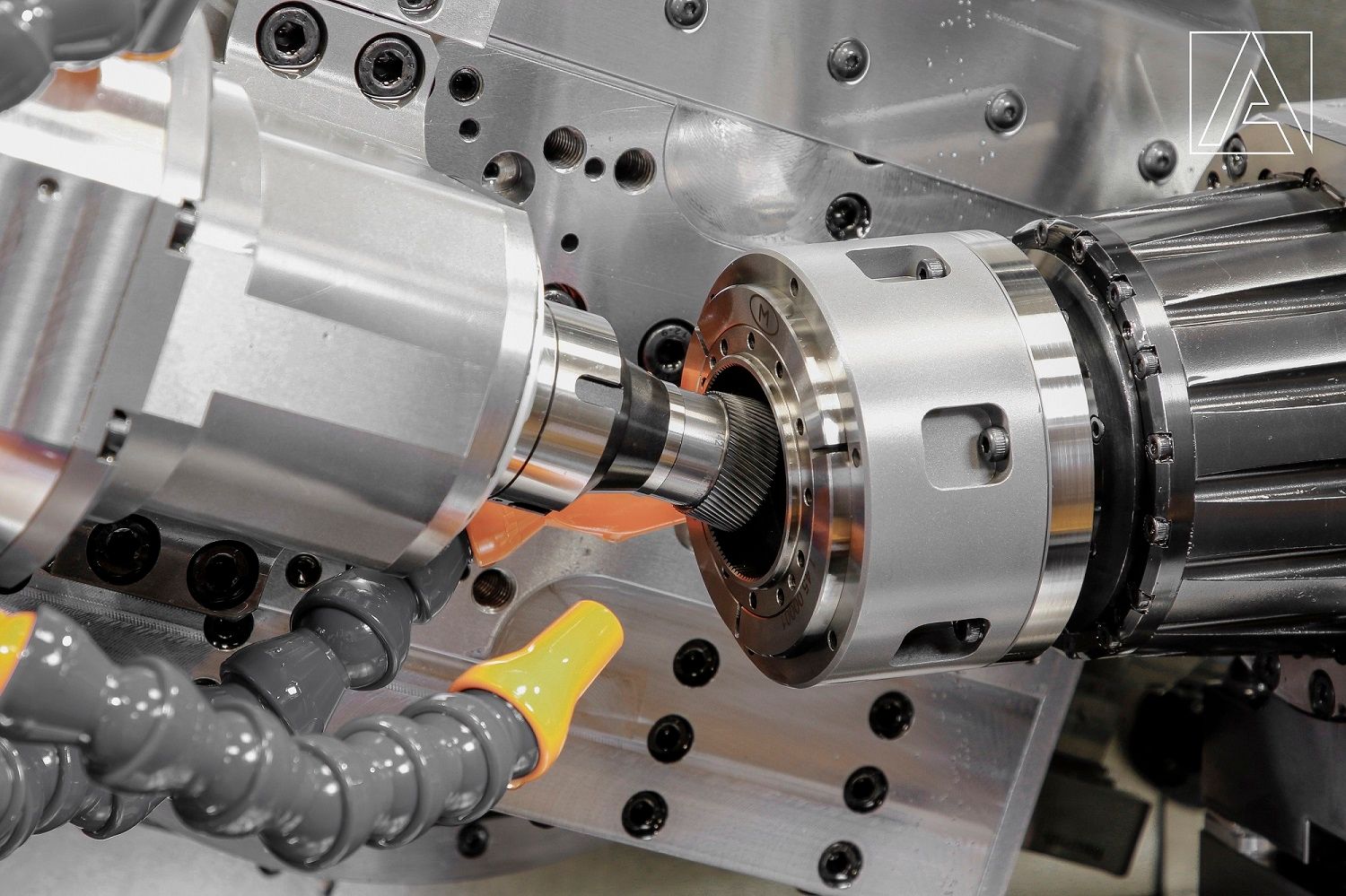

With the optional quick-change system, machine operators can switch from one configuration to the next in only 30 minutes. In configuration I, both the C axis and the C’ prime axis are equipped with driven spindles. This setup leads to an increased cutting quality, more torque, and more rigidity. This set-up offers the A axis +/- 50° swing. “This configuration is ideal for the production of spur, helical, bevel, crowned and face gears”, reports Mr. Affolter.

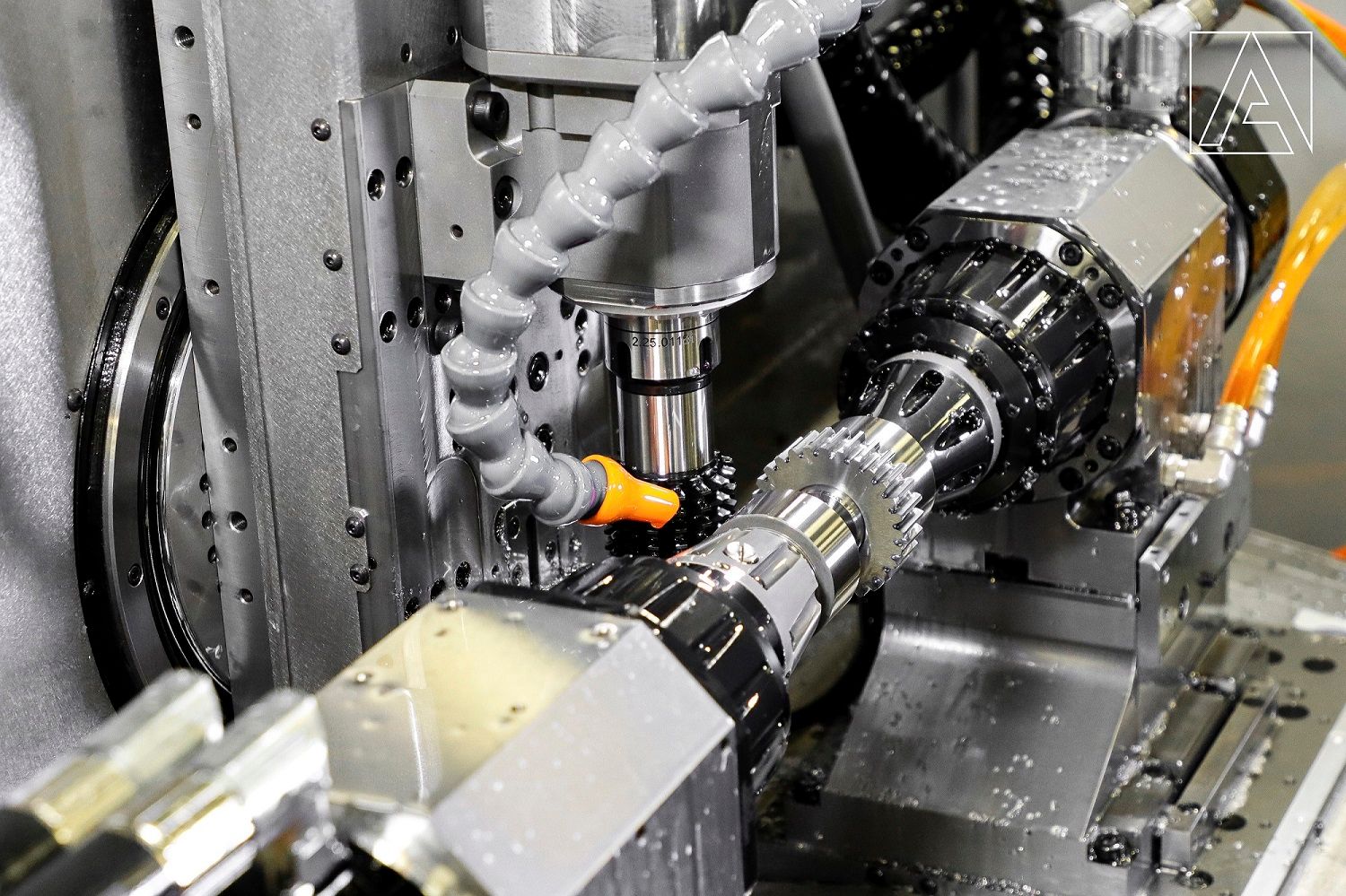

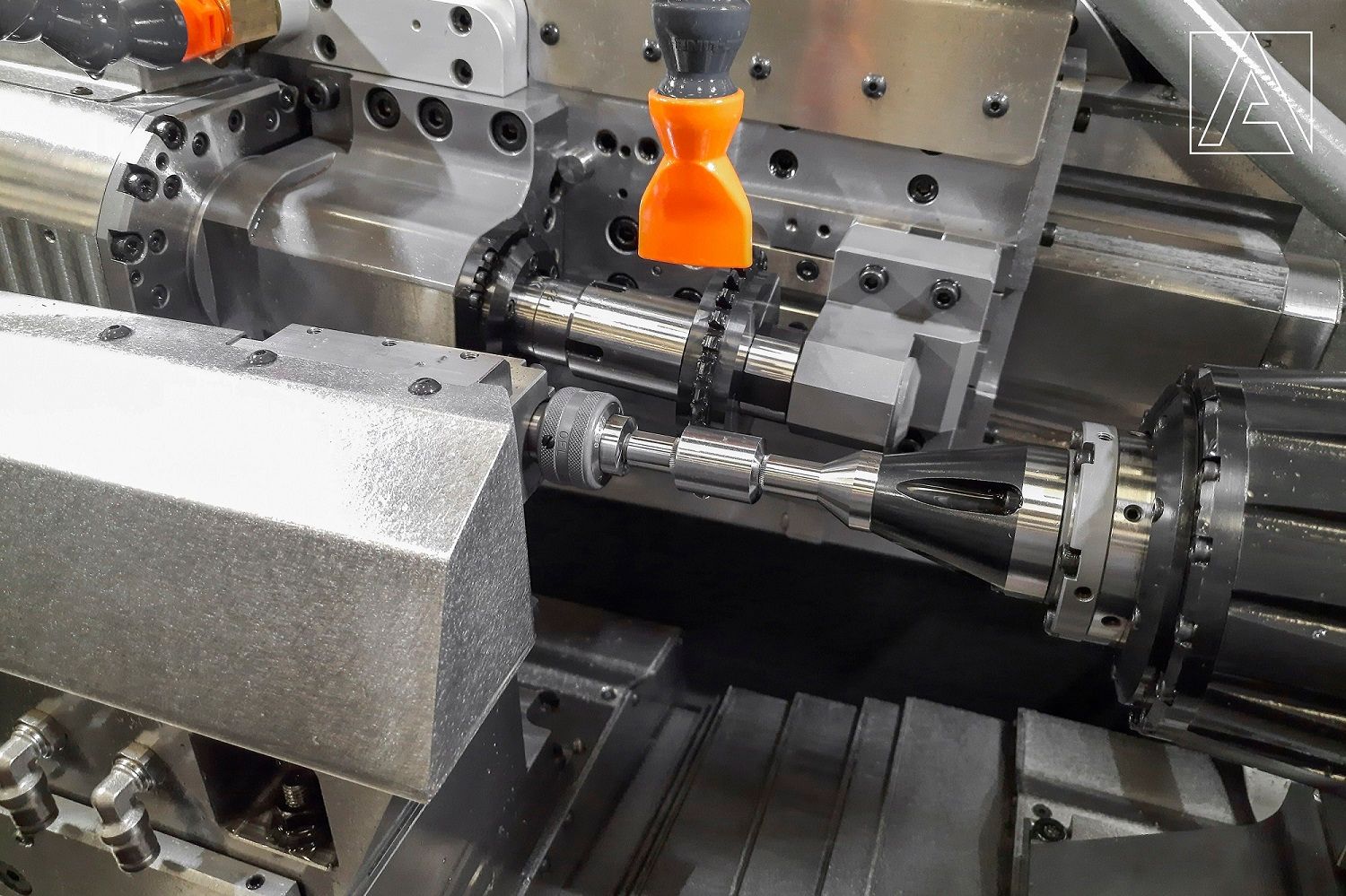

With a tailstock on axis C and a spindle on C’ prime – configuration II – the operator gets more flexibility. The A axis can move from -50° to +115°, making worm milling possible. This configuration can also be used for all gear types mentioned above. In configuration III, the C axis remains empty, and the C’ prime axis is equipped with a driven spindle. Vincent Affolter: “This configuration is designed for the power skiving of internal gears. The production of face gears is possible, too.”

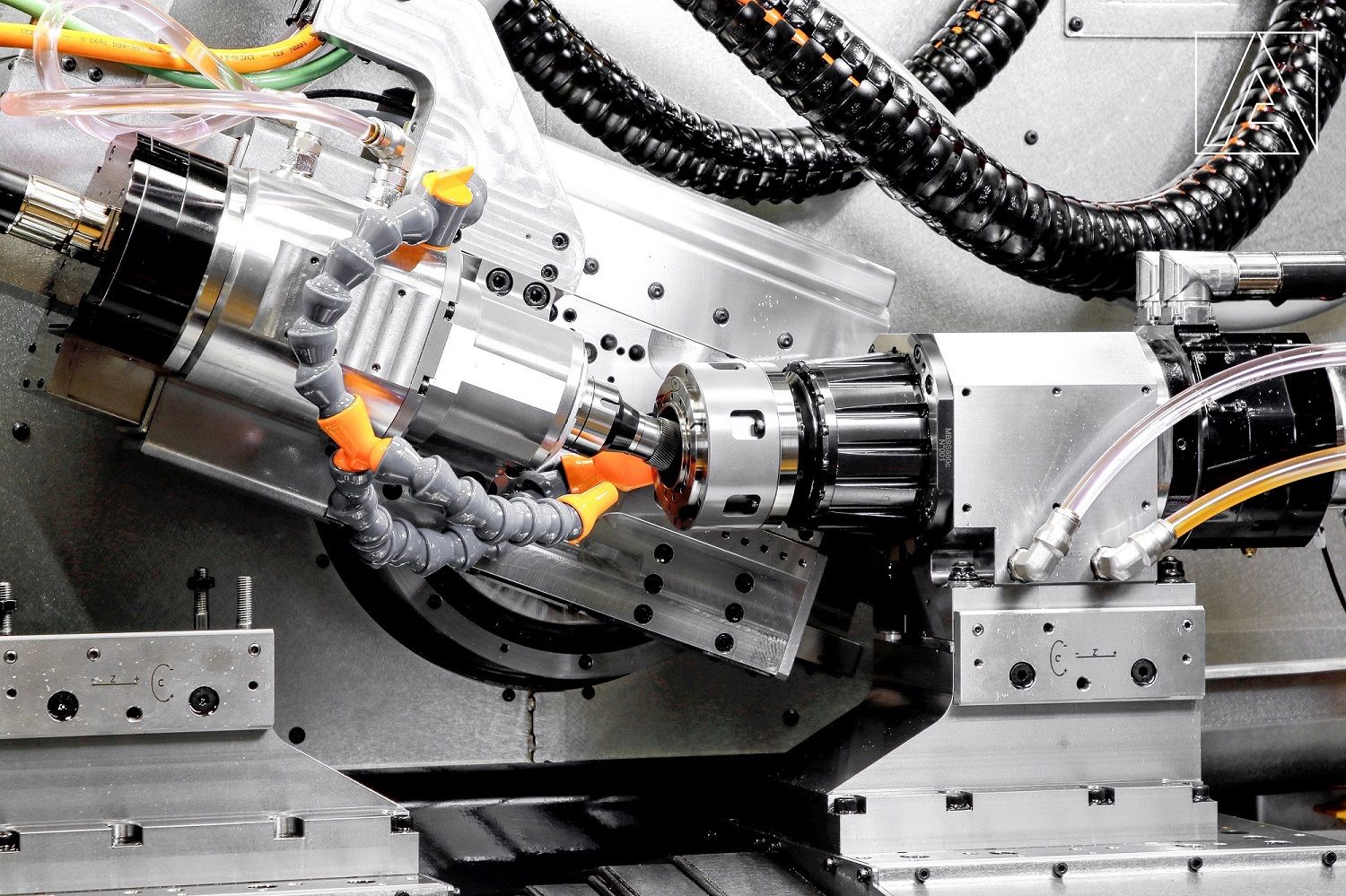

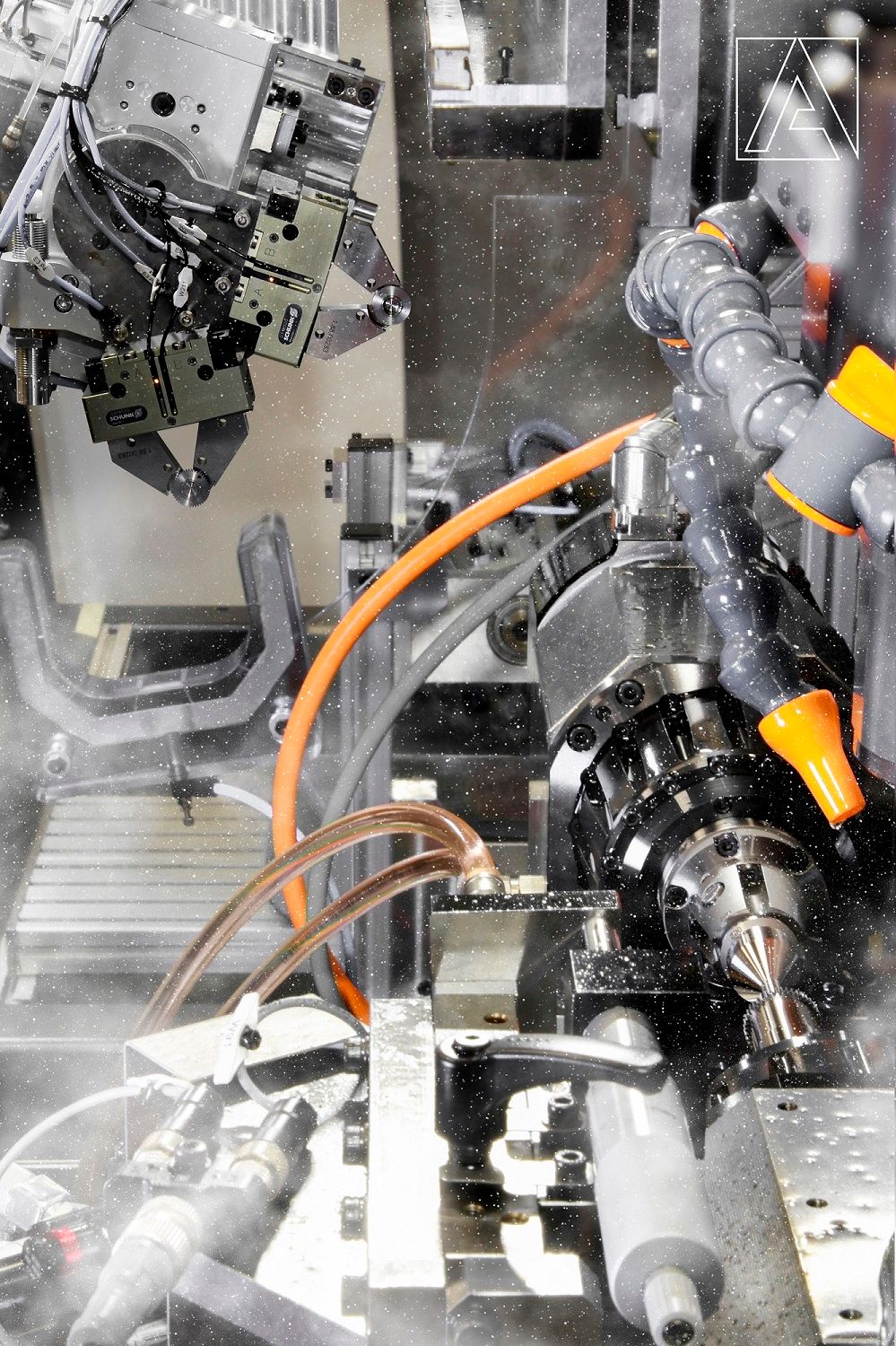

Telescopic Part Loader AF72

The part loader AF72 has been specifically designed for the AF160. With its double gripper system for parallel loading and unloading and a telescopic arm, different configurations depending on the volume, product and application can be chosen for an easy and efficient loading of the parts. The AF72 can be equipped with up to five feeding rails, enabling to preload more parts and let the machine work autonomously for more than 24 hours, with a proper configuration. Mr. Affolter: “The telescopic arm ensures that the working area in the machine remains clear. The arm retracts after loading the parts, giving the operator a good view of the processes during machining.”