Wera Profilator Introduces Scudding Process

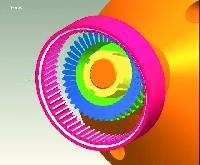

Introduced for the first time at EMO 2007, the Scudding process is a continuous cutting operation that uses a tool design similar to a helical shaper cutter. It can be used for a wide range of gear applications including involute gears like sprocket or ring gears or on non-involute or non-symmetrical gears like belt pulleys or straight synchronic gears.

In Scudding, the cutter feeds directly through the workpiece as the cutter and workpiece spin in a synchronized fashion. According to Scott Knoy, vice president of sales at American Wera Inc., the process can cut a gear in nearly the same time as hobbing and can be five to six times faster than shaping an internal gear.

The machine was originally developed for sliding-sleeve internal splines for manual transmissions, but it was soon realized that it could cut internal gears, external gears and non-symmetrical forms, and it could hard-finish internal gears with a carbide cutter.