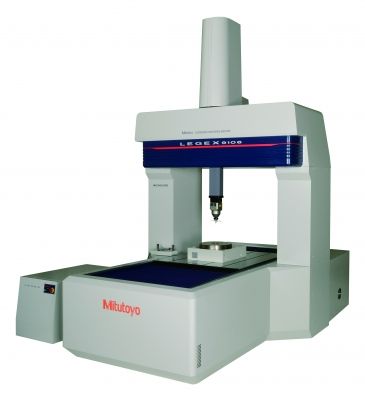

Mitutoyo LEGEX 4 CNC Machine Provides High-Accuracy Measurements

Mitutoyo America Corporation recently released the latest LEGEX CNC coordinate measuring machine (CMM). The LEGEX 4 delivers accuracy in length measurement of E0,MPE = (0.28+L/1000) μm.

With the advancement of scientific and industrial technologies and driving demand for improvements in high-accuracy manufacturing, Mitutoyo LEGEX produces applications such as ultra-precise molds, components and aspherical lenses in the automotive, aviation and medical instrument industries, and calibration of master gages for research institutes. To meet these needs, Mitutoyo started from the elemental technology level and worked upward, with the aim of eliminating all possible sources of measurement error.

Key features include: sources of static and dynamic error minimized to realize world-leading measurement accuracy of 0.28 μm; fixed-bridge structure with moving table; base is made from spheroidal graphite (ductile) cast iron in a sealed-structure design to provide high rigidity and vibration-attenuating characteristics; high-rigidity structure and feed mechanisms increase accuracy and improve cycle times; thermally symmetric structure features full covers around the main body to reduce possible impact in ambient temperature changes; vibration-dampening unit is standard; an air server stabilizes the air temperature to 20°C±0.1°C.