GWJ Technology Extends Involute Gear Output Options

GWJ Technology GmbH has extended the output option of tooth forms of involute gears. GWJ has extended the output of tooth forms in 2D DXF format in its calculation modules single cylindrical gears, cylindrical gear pairs, planetary gear trains, three- and four-geartrain systems, gear racks and involute splines as part of the new versions of its calculation solutions eAssistant and TBK.

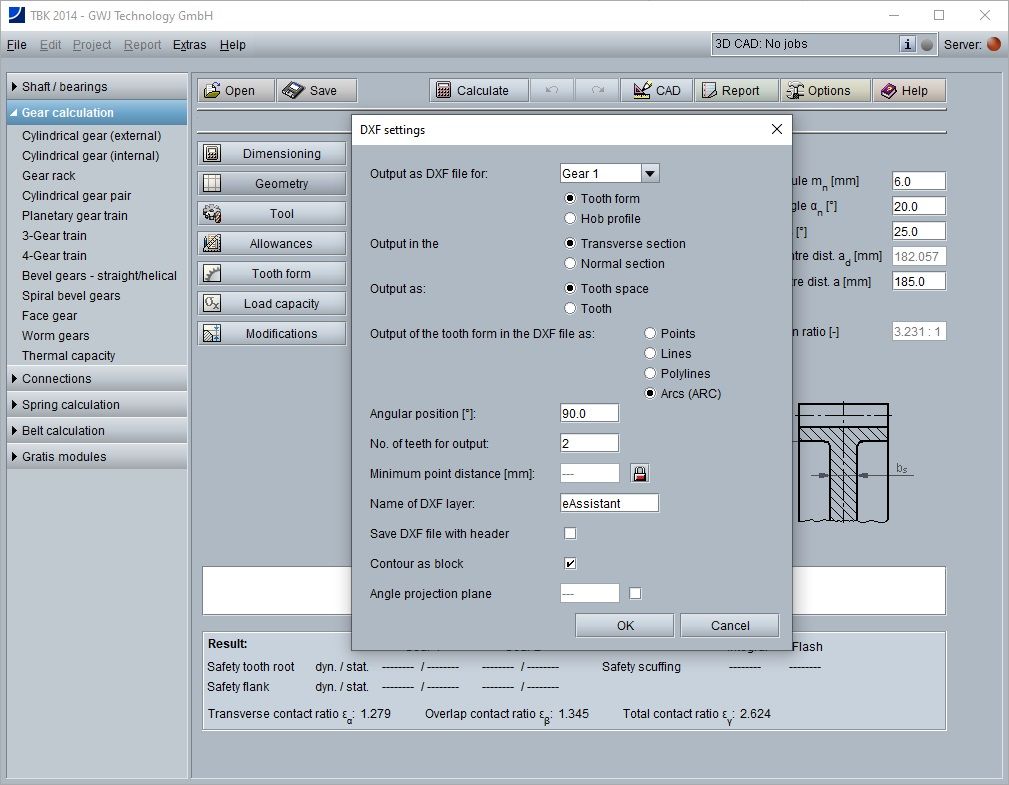

In addition to the output of the tooth forms of the tooth space as points, lines, polylines and circular arcs and a minimum point distance that can be predefined if required, the tooth can now also be output instead of the tooth space. In addition, the angular position can be specified for this. Furthermore, the user can define the number of teeth to be output.

As a new option, the tooth form contour can be exported either as a block definition or without grouping as a block. This makes further processing easier, depending on the CAD or CAM system. In addition, the tooth form can now also be projected onto a specified tilted plane. For this purpose, the user can specify an appropriate angle for the tilted projection plane.

For helical gears, the tooth form can also be output as a tooth space in normal section as an alternative to transverse section. In addition, it is now also possible to output the cutter profile in normal section when calculating the tooth form with a hob. In addition to the 2D DXF output and the 3D CAD plugins for Autodesk Inventor, SOLIDWORKS, Solid Edge and Siemens NX, the 3D output in the neutral formats STEP and IGES has also been possible in eAssistant and TBK for some time.